Popularity frame technology due to lower construction costs and high speed of construction of buildings. Both commercial structures and residential buildings are built on it. Frame baths are especially in demand today. You can easily build them yourself on your own country plot. A 5x5 frame bathhouse is one of the popular construction options that you can build yourself.

Where to start building a bathhouse

Before construction begins frame bath It is worth planning the placement of the building. Pay attention to the following features:

- It is important to determine where the bathhouse will be located - separately or near the selected building on the site.

- Choose a place to install a bathhouse, taking into account the location utility networks, and also mark the routes for laying communications.

- Find out the soil characteristics on the site in order to choose a foundation.

- Develop a new or choose an existing bathhouse project, taking into account your own requirements.

Advice! The more detailed the bathhouse design is, the easier its implementation will be.

Many organizations offer ready-made projects. You can order from them individual project. The minimum size is 3x4 m. Optimal ratio sides of the bath - 5x5 m.

Own bathhouse project

In order not to waste time creating drawings, you can choose an already created project as a basis. In this case, the layout of the frame structure must correspond to the building area. Then it remains to make some amendments to it.

For a future frame building project, it is important to consider:

- layout - it is important for the rational distribution of space;

- costs for the construction and operation of a frame bath;

- terms of work;

- features of the foundation structure.

All interior spaces arranged in accordance with the number of pieces of furniture and their sizes. For example, when creating a drawing of a frame structure, the length of the benches is taken into account. To make the rest room comfortable after the reception water procedures, a table, sofa and armchairs are installed in it.

It is important to correctly determine the location of the dressing room in frame structure. It is designed in such a way that cold air does not enter the bathhouse when the doors are opened. In the washing compartment of the frame structure, a location for a water tank should be provided. The brooms are dried in a warm attic. Comfortable stay possible when creating a veranda or terrace.

Advantages of frame structures

The construction of a frame bath requires compliance with certain rules. This structure consists of load-bearing structure, which is covered with OSB panels. Insulation and vapor barrier are laid between the wall slabs.

Advice! You can save on building a frame structure by choosing straw or sawdust for insulation.

A frame bath made of similar materials is light in weight and therefore does not require the creation of an impressive foundation. It is easy to build it yourself.

Obvious advantages frame construction are:

- low costs for foundation construction;

- all work can be done independently, without using heavy equipment;

- short construction time.

Frame technology also has its disadvantages that require mention. The main disadvantage of such baths is their increased fire hazard. For this reason, it is better to carefully treat all structural elements with refractory compounds. For wiring in a frame structure, non-combustible casings should be selected.

Important! In a frame bathhouse, special attention is paid to moisture insulation of the walls. Mineral heat insulators perfectly absorb moisture, as a result of which their positive properties are lost.

Ready-made baths

It is not always possible to start building a bathhouse with your own hands. In this situation, they buy a ready-made structure. The kit includes the following items:

- mounting beam - it is used to create a frame;

- fastening kit;

- flooring material;

- roofs;

- wall panels;

- documentation package.

The set of documents contains project drawings and a description of the assembly instructions.

Attention! The walls in already manufactured baths are made of SIP panels, which facilitates the assembly process.

Materials

Materials are prepared in advance so that there is no need to purchase them in addition. For any frame bath you need:

Important! It is better not to use polyurethane foam for insulation. At high temperatures it begins to melt. In addition, this material is flammable.

You will also need to prepare nails and screws of various lengths. Considering high humidity inside the bathhouse, galvanized fasteners should be used.

Algorithm for building a bathhouse

A column-type base is best suited for a frame bath. It can be built using asbestos-cement pipes. You will need elements with a diameter of 20 cm and a length of 2 m. They should be buried in the wells to 1.5 m and filled with concrete-crushed stone mortar. The number of pillars varies depending on the size of the structure. For a 3x4 m frame bath you will need 12 pieces. When building a 5x5 m bathhouse, you need to prepare 18 pillars.

After installing the bathhouse supports, a timber frame is attached to them. The elements are fastened with nails. Roofing material must be laid under the strapping beams to ensure waterproofing.

Important! To ensure the tightest fit of the strapping to the foundation of the bathhouse, it is attached to the supports on metal corners.

Logs from boards are laid on the frame - they will be the basis of the bathhouse floor. The frame is treated with an antiseptic and fire-resistant agent. The installation of bath walls is carried out in the following order:

- Supports are installed in the corners, between which intermediate posts are placed.

- The sauna wall cladding sheets are secured to the racks with self-tapping screws.

- After finishing the sewing of the walls, openings for doors and windows are formed.

Important! When sheathing the walls of the bathhouse with OSB sheets, you should check their correct location. To do this, use a level.

The rafter system for a frame bath is assembled on the ground and then raised to the roof. Only then the sheathing is attached and the roofing is laid. After installing the main frame, doors and windows are installed. To build a frame bath yourself you will need:

- three days to install the foundation;

- three days to install the frame with the walls;

- two days for the rafter system;

- two days for laying the roof, installing windows and doors, as well as finishing.

Knowledge of these features helps to design and build durable and practical sauna for the whole family.

Internal and external decoration of the bath

For exterior finishing frame baths use imitation timber or siding panels. Interior decoration requires special attention. First you should choose a lining. For the rest room and vestibule, you can choose pine. It requires no maintenance and looks quite impressive.

The steam room is decorated with linden or larch. These breeds are not afraid high temperatures and are able to retain color. Sometimes other wood is chosen:

- Abashi is a tree from tropical forests that has low thermal conductivity;

- cedar - when heated, it begins to release essential compounds that are beneficial to the body;

- aspen - this tree is resistant to rotting and mold development.

Important! The lining is attached to the vapor barrier in such a way that there is a gap between the wood and the foil material.

A simple project for a 5x5 frame bath

When creating your own bathhouse, you should pay attention to existing projects. Spacious building frame type 5x5 has several types of premises:

- vestibule - clothes hangers and a refrigerator are placed here;

- a relaxation room in this room should be equipped with a table and a sofa;

- washing - it should warm up well;

- steam room.

The steam room in the bathhouse should be finished with aspen clapboard. In this room they install corner shelves, having dimensions of 90x270x270 cm. An additional narrow shelf is also installed in the steam room. The oven is lined with 120x120 cm bricks. A small window is made in the steam room, 30 cm wide.

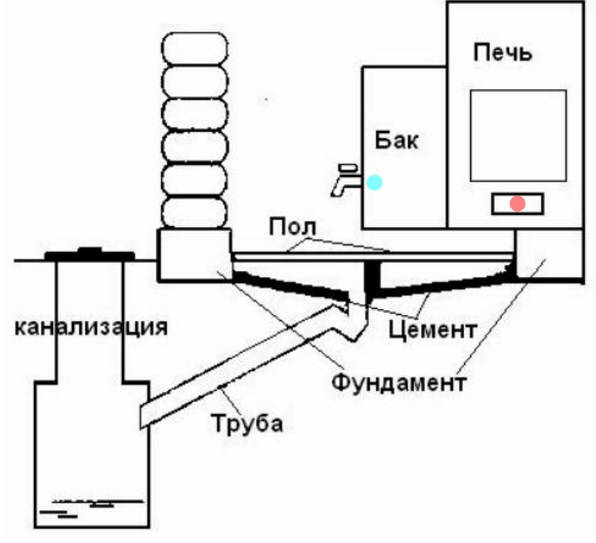

In the washing compartment it is convenient to place a shower stall 90x90 cm. There is also a 90x200 cm lounger and a tank with hot water. The relaxation room in the bathhouse is made spacious - 190x320 cm. A table with a sofa is installed in this room. The window in the rest room is made large so that a lot of light enters it.

A 5x5 frame bath is installed on a columnar foundation. This is due to its low weight and low load on the ground.

When building a frame-type bathhouse, you should follow the advice experienced builders. This will help build a durable building. It is important to follow these recommendations:

- It is worth very carefully securing the vapor barrier layer at the junction of the walls and floor of the bathhouse. This affects the durability of the building.

- Additionally, you can create reliable thermal insulation for a frame bath from the street side. To do this, additional layers of hydro- and thermal insulation are attached under the lining of the bathhouse.

- The inside of the bathhouse lining should not be painted or opened with varnish compounds. Such compounds can release toxic substances.

The ceiling and flooring in the bathhouse are insulated with special diligence. It is necessary to use the same materials that were used to insulate the walls. A frame bath is a profitable and forward-thinking solution. Its construction will not take much time. If you develop a bathhouse project in detail and prepare everything necessary materials, you can build a bathhouse quickly and efficiently. Such an object will become a source of pride for the owners of the site.

conclusions

Build frame bath 5x5 on your site is quite simple. A light columnar foundation is chosen as the base. The walls are made of beams and OSB panels. It is important to properly waterproof the grillage and roof elements. This will extend the life of the building. Based on ready-made projects, you can create own drawing frame bath that meets safety and cost-effectiveness requirements.

There is only one way to build a bathhouse quickly and inexpensively - frame. If you follow the basic rules, the construction will be in no way inferior to its brick and timber counterparts.

We design a bathhouse - different space options

We begin work on the bathhouse with design. At this stage, it is necessary to decide on the size and configuration of the future structure. If your requirements are minimal, you can build a 3x4 m bathhouse. It will have enough space for a steam room for several people with an area of 6 m2. The remaining space can be allocated to a rest room. If you sacrifice the rest room, there will be enough space for a locker room and a vestibule. And if you equip such a bathhouse with an attic floor, you won’t have to give up the rest room.

If the bathhouse will be used as a place to hang out with friends, it is better to make it larger, for example, 6x4. In this case, you can equip it enough spacious room relaxation area of about 14 m2, as well as a steam room of 5 m2 and a small bathroom.

And if you make a 4x6 bathhouse with an attic, then on the ground floor there can be a steam room and a washing room, as well as a relaxation room and a terrace. All attic floor, which is about 20 m2, can be allocated for a rest room.

If the size of your plot allows, and the budget is not very limited, make an attic bathhouse measuring 6x6 m so as not to deny yourself anything. There is room for all the necessary premises, as well as a terrace and a spacious balcony.

Large steam rooms are much more difficult to heat to the required temperature and then maintain the temperature at the same level. Therefore, if there is no need for a large steam room, it is more advisable to allocate no more than 4-5 m2 for it. This will save fuel and time for heating the room.

In order not to rack your brains over the layout, you can take as a basis the ready-made projects offered on our website. If necessary, adjust the layout as desired. When the plan is ready, be sure to draw up a drawing diagram of the frame of the walls and roof.

The frame of the walls is quite simple - it is based on racks, which are located in increments of 600 mm, if measured from the centers, or 575 mm, if measured between the racks. The top and bottom of the racks are connected by strapping - a horizontal beam or board. In the corners, the racks are reinforced with braces. There are horizontal lintels above doorways, as well as above and below window openings. Floor beams are calculated and laid in the same way as in the construction of ordinary houses.

Having such a drawing in front of you will prevent you from making mistakes during the assembly process. In addition, it will allow you to calculate in advance required amount lumber.

Columnar foundation - building the foundation

Since a frame bathhouse is light in weight, in most cases a columnar shallow foundation is sufficient for it, provided that the soil is stable. On unstable soils it is better to perform pile- screw foundation. If you are planning a cellar or arranging other rooms, you will need strip foundation. In other cases, it is better to abandon it, since the construction of such a foundation is very expensive and labor-intensive.

Regardless of what kind of foundation you are going to build, first prepare the site - first of all, you need to properly outline it. Be sure to make sure that the diagonals of the site are the same length. Then get rid of the plant layer. To prevent plants from sprouting under the bathhouse in the future, treat the soil with fungicides.

Now you can begin building the foundation itself. If the base is columnar, you will need the following materials:

- sand;

- crushed stone;

- cement mortar;

- concrete foundation blocks (can be replaced with brick);

- bitumen mastic;

- roofing felt;

- timber 150x150 mm.

After preparing the materials, mark the area for the posts, which should be spaced in increments of 1.5–2 m. Then dig holes to a depth of about 40 cm. Cover the bottom of the holes with crushed stone and sand 10 cm thick. Compact each layer thoroughly. Level the surface of the embankment in a horizontal plane.

Place two in the pits concrete blocks, then apply the solution and place two more blocks with dressing on top. When laying blocks, make sure that the pillars are installed strictly vertically. Then work the blocks on top bitumen mastic and put a couple of layers of roofing felt.

After this, you need to make a grillage, i.e. lay timber around the perimeter of the foundation and fasten it together. During installation, make sure that the angles of the grillage are 90 degrees. It is advisable to make the corner connection of the grillage beam “in the paw” or at least “in half a tree”. Then you need to lay the floor beams on the posts and cut them into the grillage.

A pile-screw foundation is even simpler - piles are screwed into the ground according to the principle of a conventional drill. Their depth must be at least two meters. During the deepening process, you need to ensure that the piles are positioned vertically.

The tops of the piles are then trimmed so that the edges are at the same horizontal level. After this, a grillage is welded to the piles, which is usually made from I-beams. The same beams are used for flooring.

On metal beams you need to secure the 150x150 mm beam with bolts. It will serve as a strap for the frame posts.

Assembling the frame - materials and installation

To build the wall frame you will need the following lumber:

- timber 150x150 mm;

- timber 100x150 mm;

- board 150x40 mm;

- steel corners;

- wooden dowels.

Be sure to treat all lumber with antiseptic impregnations. They will protect the tree from negative biological influences and also make it more resistant to moisture.

The work begins with the installation of racks in the corners of the building, which are made of 150x150 mm timber. At the end of each rack, drill a hole for the dowel with a depth of 80-100 mm. Make the same holes in the grillage at the corners of the building. Then hammer the dowels themselves into the grillage and place the racks on them. Additionally, strengthen the racks with steel angles and self-tapping screws.

Then the racks must be strengthened with braces, as shown in the diagram above. To make braces, use 150x40 mm boards. Cut the ends of the braces at the angle at which they will adjoin the frame and posts. To fix the boards, use self-tapping screws and corners.

Next, install intermediate wall posts with a pitch of 600 mm, made of 150x40 mm boards. To attach the racks, use steel corners, which should be located on both sides of the brace. In addition, connect the intermediate posts to each other, as well as to the corner posts, using jumpers made from the same boards. Place jumpers in checkerboard pattern, i.e. at different levels.

Tie all the racks from above with a strapping, which is made from 100x150 mm timber, it will also serve as a Mauerlat for the roof. Then install horizontal strips above and below the openings. For the slats, use the same board as for the racks.

Then install the racks using the same principle interior partitions– connect them from above and below with strapping, and also strengthen them with braces and jumpers. This completes the construction of the frame.

Now you need to lay the floor beams, for which you can use 100x150 mm timber. Place them with the edge on the harness and secure with the corners. The pitch of the beams must correspond to the pitch of the rafters - this is usually 900–1000 mm.

Installing an attic roof

As an example, let's consider a roof, since it allows you to get an almost full second floor with a minimal increase in financial costs. If you are interested in or, check out other articles on our portal.

For the attic roof you will need the following materials:

- timber 100x150 mm for racks;

- boards 150x50 mm for rafters;

- boards 150x20 mm;

- slats;

- superdiffuse membrane;

- roofing material.

The work begins with the installation of the supporting structure. For each truss, two racks are installed, which are connected at the top by beams. Those. under each roof truss there is a U-shaped supporting structure.

When installing the supporting structure, it is necessary to correctly determine the position of the racks. Since the rack with the lower rafter and mauerlat (floor beam) forms a rectangle, the distance from the wall to the rack depends on the height of the attic and the angle of inclination of the lower rafter. Knowing the angle of inclination of the rafters and the height of the rack (determines the height of the attic room), you can calculate at what distance from the edge the rack is installed using the Pythagorean theorem, i.e. you need to find out the length of the smaller leg.

Secure the posts to the frame and floor beams with self-tapping screws and angles. Additionally, reinforce them with braces. Then connect both posts with beams. Using this principle, install U-shaped parts on all floor beams. Connect all the resulting load-bearing elements at the edges with purlins, as shown in the diagram above.

Now you can install the lower rafters. They are cut from below and attached to the harness, and from above - to the purlin, in which the grooves are pre-cut. Next, you need to secure the racks in the center of the jumpers of the U-shaped parts. The height of the racks determines the angle of inclination of the upper rafters. Connect all the posts with a ridge girder.

To complete the attic frame, install the upper rafters, which rest on the lower and ridge purlins. First, cut the grooves for the rafters in the purlins. Immediately waterproof the roof - secure the super-diffuse membrane to the rafters with a stapler. Place a special self-adhesive tape over the staples to ensure a tight connection. Please note that the membrane sheets should overlap each other by 20–25 centimeters.

A superdiffuse membrane is capable of transmitting moisture in one direction. Therefore, it should be located on the roof with the smooth side outward and the rough side inward. If it is not secured correctly, moisture can penetrate deep into the insulation, as a result of which it will lose its thermal insulation properties.

Be sure to secure the slats on top of the rafters, which will serve as a counter-lattice. Then attach 150x20 mm boards perpendicular to the slats. As for the sheathing pitch, follow the manufacturer’s recommendations roofing material, which you purchased for the bath.

The roofing covering is mounted on top of the sheathing standard scheme– sheets of material must overlap each other lengthwise and crosswise. Screws or nails are located at the crest of the wave.

We insulate the walls, roof and floor of the bathhouse

To insulate the walls you will need:

- basalt wool 150 mm thick and density 25-35 kg/m 3;

- vapor barrier film;

- moisture-windproof membrane (super-diffuse);

- wooden slats.

To vapor barrier a steam room, it is more advisable to use foil vapor barrier material. It will not only protect the structure from moisture, but will also reflect heat into the room.

Let's start with insulating the walls from the inside. To do this, apply self-adhesive double-sided sealing tape to the racks. Then glue the waterproofing film to the tape. Be sure to place the canvases with an overlap of at least 15 centimeters. Glue the joints on both sides sealing tape. Additionally, secure the foam with a stapler. The result must be an absolutely sealed circuit, otherwise moisture will penetrate inside the walls and the frame will quickly become unusable.

Then lay mineral wool slabs into the frame space. Make sure that the insulation fits tightly to the structural elements and to each other. Carefully fill all the resulting cracks with cotton wool scraps.

Next, you need to secure a moisture-windproof membrane on the outside of the walls. It is installed according to the same principle as a vapor barrier - a sealant is glued to the racks, then the membrane itself is attached using a stapler. On top of the film on the racks it is necessary to fix slats with a thickness of at least 20 mm. Place the same slats on the racks with inside walls, they will serve as lathing for the lining.

The same technology is used to insulate the roof - mineral wool is laid between the rafters, then covered from the inside with a vapor barrier. A lathing for lining or other materials is mounted on top of the vapor barrier. finishing materials.

The floor is insulated a little differently - first of all, you need to make a rough flooring between the floor beams from the boards. Then a waterproofing film is laid on the beams and flooring (you can use a regular vapor barrier). Logs are laid on top of the film as when installing a regular floor.

Insulation is placed in the space between the joists. You can use any material, both slab and bulk, such as ecowool or expanded clay. Another layer of film is laid over the logs and then the flooring is made of boards.

To insulate the ceiling, attach a vapor barrier on the side of the first floor, and then make a rough ceiling from the boards. Then, on the second floor side, you need to fill the space between the beams with insulation. A vapor barrier and plank flooring are laid on top of the beams.

Sheathing the walls - the final stage

For exterior wall cladding, it is best to use OSB-4 with a thickness of 12-15 mm. The sheets need to be cut so that the edges fit on the rack. There should be no hanging edges. In the locations of window and doorways You need to make cuts using a jigsaw or hacksaw.

To fasten the sheets, use phosphated self-tapping screws 60-70 mm long. The distance from the edge of the sheet to the screw should be 10 mm. The fastener spacing along the edges should not exceed 150 mm. In the center of the sheets, the screw pitch can be increased to 300 mm.

Be sure to provide a distance of about 5 mm between the edges of the sheets, i.e. the so-called expansion joint. If this is not done, the sheathing sheets may become deformed as a result of thermal expansion. All seams must be filled with foam.

Cover the gables of the building in the same way. Then the walls can be finished with any “dry” facade finishing materials, such as lining, siding, thermal panels, etc. Line the walls with clapboard on the inside. If you do not know how, dedicated to this topic.

That's all the main points. Even if you are a beginner, you can build a small sauna box in one to two weeks.

One of the first and most important stages in the construction of any building is the arrangement of a supporting structure that can withstand the loads created by the structure and ensure its safety and integrity for many years of service. The compact 3x4 m bathhouse is no exception. Despite its objectively modest dimensions, this building also requires a high-quality and correctly installed supporting structure.

While studying the information below, you will learn how to choose a suitable foundation for a 3x4 m bathhouse, on the basis of what indicators the choice of a specific structure is determined, how to correctly calculate it and directly construct it. The information you receive will help you choose the best way a suitable type and optimal dimensions of the support, and also refuse the services of third-party contractors, significantly saving the budget allocated for the construction of the bathhouse.

There are 2 key requirements for the foundation of any building. Firstly, the supporting structure must be as reliable and durable as possible. Secondly, the foundation design must be such that seasonal soil movements do not have a significant impact on it.

When choosing a foundation design and its overall dimensions, in addition to all other factors, it is necessary to take into account the type of soil at the construction site and the depth of soil freezing, according to which such a significant indicator as the depth of the supporting structure is determined. While studying third-party manuals, you probably came across recommendations from not entirely competent authors to lay the foundation to a depth of 60-80 cm, etc. In some cases, of course, such advice is relevant, but not always. The point is that in different regions countries, the soil freezes to different depths and this must be taken into account. Information regarding these points is given in the following table.

In addition to the depth of soil freezing, it is necessary to take into account its type. The images show what types of soils there are and what they look like.

Properties, composition and types of soils

Properties, composition and types of soils  Classification of soil varieties

Classification of soil varieties

The dependence of the laying depth on the level of groundwater passage and soil freezing is reflected in the following table.

Based on all of the above, we can provide a table with recommendations for choosing the type of foundation for a 3x4 m bathhouse in accordance with the properties of the soil at the construction site.

| Foundation | Illustration | Priming |

|---|---|---|

| Belt (prefabricated, monolithic, precast-monolithic) | Non-heaving, dry, sandy | |

| Non-subsidence clayey | ||

| Slab solid | Mobile, heaving, subsidence | |

| Pile | Almost all types of soil |

Band support structures are the most common and...

Slabs are somewhat less common, because cannot be used in combination with all types of soil - too mobile soil will simply destroy the slab.

Pile foundations are the most versatile, however, the purchase and installation of screw piles directly leads to an increase in the final cost of the work performed, which is not acceptable for every developer.

More a budget option supporting structure, in many ways similar to a pile foundation, is a columnar foundation.

In view of the above, we suggest that you familiarize yourself with the instructions for the calculation and construction of the most commonly used types of support foundations: strip foundations and columnar structures.

Foundation calculation: basic principles and important notes

The calculation procedure for strip and column type foundations will differ. Task: to determine whether the foundation with the selected parameters can withstand the load created by the building from the materials chosen by the developer, as well as by precipitation.

Calculation of strip structure

In the example under consideration, a monolithic system of concrete and crushed granite is calculated. The following image clearly demonstrates the plan and dimensional characteristics of the foundation being built. Using the recommendations below as a basis, you can independently adjust the support plan and the procedure for calculating loads.

Our strip foundation has dimensions of 4x3 m. The design is inclined, expanding towards the bottom. Thanks to this feature, higher resistance to soil heaving forces on the site will be ensured.

The 4-meter sections will be subject to the heaviest loads in the structure under consideration, because the ceiling and joists rest precisely on the side walls. Let's calculate what load the ceiling and logs of the bathhouse will create on 1 m of the foundation base. To find the total load, you need to determine what load on concrete structure will create snow, roof structure, ceiling, and also walls. Additionally, the loads created directly by the material used to manufacture the supporting structure are taken into account.

Snow loads are determined by multiplying the standard load created by snow in a particular area by the load area of the roof structure for 1 m of the support system. The value of the standard snow load is determined according to the relevant documentation - here it is SNiP number 2.01.07-85. You can also navigate using a special map.

Additionally, standardized values of the coefficients used to find snow loads will be given in the corresponding table.

To determine the load load of the roof structure per meter of base, it is necessary to divide the total area of the roof by the length of the support. For the calculation, only the lengths of the side strips are used (4+4=8 m). The length of the end parts (3+3=6 m) does not appear in this calculation, because the roof beams, as noted, will rest specifically on the long bath walls.

We calculate snow loads in the following order:

- find the total area of the roof structure. To do this, we multiply the values of the doubled length of the roof slopes and the length of the roof eaves. We calculate the length of the slope as follows: 3/2=1.5/cos 45=2.86 m. We calculate the total area of the roofing structure as follows: 2*2.86=5.72*4=22.88 m2 (rounded to 23 m 2);

- We calculate the load area of the roof structure for a meter of support: 23/8 = 2.88 m 2 ;

As an example, we calculate the support system for a region included in zone II for snow loads. The specific snow load here will be 70 kgf/m2 (we will show the values for other zones in the table). We calculate it like this: 2.88*70=202 kgf.

We determine the load created by the roofing structure. We need to find the load value from square meter horizontal projections of the roofing system. We have a 1.5 m tiled gable roof. It is mounted at an angle of 45 degrees.

We select the appropriate value in the following table.

And we calculate: 1.5*80=120 kgf.

To determine the load from the floors, first look at the table.

In this example, the cargo area also falls on the sides of the supporting structure (the floors rest on the side bath walls). We find the load area of bath floors for each meter of the foundation system as follows: 4 * 3 = 12/4 = 3 m 2. Density wooden floor– 300 kg/m3. We find the load like this: 3*300=900 kgf. If the ceiling in your bathhouse is made of reinforced concrete, in the calculations we use a value equal to 500 kg/m3, instead of the mentioned 300 kg/m3, which is relevant for wooden structures.

Let's find out what load will be created on the bath base external walls. Let's first study the following table.

We take the load value from the table above, then multiply it by the height of our bath walls, and then by the thickness of the wall. Let's take the height of the wall to be 3 m, let's take the thickness at 0.4 m. Our walls are built from logs/beams. We count: 3*0.4*600=720 kgf.

To calculate the load from the foundation, we multiply the volume of a meter of tape and the density of the material for its manufacture. We take the density from the table.

We make a foundation of concrete and use granite crushed stone. The volume of a meter of tape specifically in our example is 0.45 m 3 . We find the load: 0.45*2300=1035 kgf.

Prices for granite crushed stone

granite crushed stone

All that remains is to find the complex load per 1 m of the sole of the strip structure in section AA (shown in the figure above).

Let's sum up the calculated values: 202+120+900+720+ 1035=2977 kgf. The supporting structure with this cross-section has an area of: 50*100=5000 cm2. We determine the pressure on the ground: 2977/5000 = 0.6 kgf/cm 2. We build on plate clay soil. For such soil, the calculated comparison of bearing capacity is equal to 1.5 kgf/cm 2. Consequently, the loads are more than acceptable, and a foundation with such parameters will serve well for many years. You can take a calculated comparison of the bearing capacity for your soil from the following table.

Calculation of a columnar foundation

Let's calculate the columnar foundation. For its manufacture we use monolithic reinforced concrete. You can see the approximate design diagram in the following image.

Note! The picture shows a foundation plan for a building measuring 6x12 m. For a 3x4 m bathhouse, the parameters will remain the same, only the number of support pillars will change (according to the standard, it is recommended to install them every 2 m, i.e. each wall will be supported by 3 pillars - each 2 in the corners and 1 in the middle of the length).

At the top, the cross-section of the supports is 400x400 mm, at the bottom - 800x800 mm. The specific dimensions in your case may differ, depending on the situation.

Let us find the total load created by the sole of the support on the soil. To do this, we need to subtract the mass of the support system from the load found in the previous calculation: 2977-1035 = 1942 kgf.

We multiply the load indicators created at the interval between the supports: 1942*2=3884 and add the weight of one support to the found value. Each of the supports we use has a volume of about 0.25 m 3 . The density of the reinforced concrete used was indicated in the previously given table. We calculate the mass of the column as follows: 0.25*2500=625 kgf. The load of one column on the soil will be equal to: 3884+625=4509 kgf. Each pillar has supporting surface, equal to 6400 cm 2 (we find it by multiplying 80 by 80). In our example, the bearing capacity of the soil is 1.5 kgf/cm2. To determine the maximum possible loads, we do the following: 6400 * 1.5 = 9600 kgf. The obtained value significantly exceeds the loads we found (4509 kgf).

A columnar foundation with such characteristics will calmly bear the loads created by a 3x4 m bathhouse and will not even “move.” If desired, the dimensions of the supporting structures can be proportionally reduced - the main thing is that the resulting calculated loads do not exceed the maximum.

At the same time, the arrangement of a columnar foundation, all other things being equal, will require approximately 3-4 times less concrete than a strip support. Excavation work will also be significantly reduced. In the next section, we invite you to familiarize yourself with the results of calculations of the required volume of material for arranging a strip support structure. You can then proportionally determine the consumption of concrete for pouring pillars, taking into account the above information regarding saving materials.

Calculation of materials for pouring the foundation

The configuration of the strip base directly depends on the selected internal layout of the bath, and the consumption of materials depends on it. In the case of a 3x4 m bathhouse, there are few options for the internal layout of the bathhouse - we will show them, and you will choose the one that is relevant for your case. The foundation will be poured with 200 grade concrete - for compact bath The indicated dimensions are quite enough.

In our area, the soil freezes to 80 cm. We lay the tape 20-30 cm deeper than the specified value. Let's take 110 cm. We equate the width of the tape (A) to 3 m, length (B) to 4 m, height (C) to 110 cm, thickness (D) to 40 cm. Depending on the layout, the following will appear in the calculations: new values. We will further describe them in the appropriate sections.

First layout option

Support for a bathhouse consisting of one room. This is what the foundation looks like.

The calculation for the tape is as follows (taking into account 10 cm of reserves on each side).

Second layout option

A more common internal bath configuration. Consists of a steam room, a wash room and a dressing room/rest room.

In this example, an additional element appears, marked E. The total length of its constituent elements is 4 m.

The foundation drawing looks like this.

It is pointless to consider other layout options for a 3x4 m bathhouse - the most rational ways of distributing the available space were presented above.

Making a strip foundation for a 3x4 m bathhouse

The structure we are equipping schematically looks like this.

Let's get to work, following the instructions from the table.

Table. Arrangement of strip foundation

| Work stage | Description |

|---|---|

| Firstly, we remove debris from the site and, in general, everything that will interfere with us during the work process. Secondly, we remove the top fertile ball of soil (usually its height is 150-200 mm). If this is not done, rotted plants in the future will ruin the foundation. It is better to try to remove the soil level and carefully level it - this will simplify the process of subsequent marking of the base (you will not have to waste time determining the highest and lowest angles, which will save time). In the future, the space of the site not occupied by the concrete strip will need to be filled with compacted soil, cleared of various types of organic matter. |

| We have leveled the site and can start marking from any angle - there will be no differences in height. At the location of any external corner, we drive a reinforcing rod into the ground or wooden block. We measure the distance to the next corner and drive a new block/rod there. We stretch the rope between the driven landmarks. Repeat for each corner of the tape. Having marked the corners of the tape, we will get pairs of bars located next to each other (as shown in the photo). For convenience, we connect them from above with a horizontal crossbar made of timber. We measure the lengths of the diagonals. If they match, everything is fine, if they diverge, we made a mistake. We repeat the marking process more carefully. |

| We dig trenches in accordance with the markings. Recommendations for choosing the optimal trench depth were given earlier. We don’t remove the soil far from it - we then use it to fill the depressions formed at the first stage of work (mentioned in the corresponding paragraph). We level the bottom and walls of the trench and compact it. If the soil crumbles, we install temporary formwork from boards. |

| We use clean fine-grained sand. The thickness of the backfill layer is from 200 mm. The higher the soil heaving index, the more sand needs to be poured (up to 600 mm or even more). It is more convenient to fill the sand in small (10-15 cm) layers. The photo shows a device for manual tamper sand. |

| The photo shows another version of the device for manual compaction of backfill. To make the sand compact better, we spill it with water. It is better to do this before laying the material in the pit to prevent it from washing away. |

| Using a level, check the evenness of the pillow. We eliminate differences by removing excess sand or adding it where the backfill is not of sufficient height. Note! In areas with high level groundwater Instead of a completely sandy cushion, it is advisable to arrange a backfill of sand and crushed stone in a ratio of 1:1.5. Crushed stone is usually poured underneath the sand. |

| The previous calculations indicated what materials and in what quantities would be needed to construct the formwork. The diagram shows in detail what elements this structure consists of. All you have to do is prepare the required number of blanks, fasten them with screws (to make it easier to disassemble in the future) and install them in the trenches. |

| In the photo you see what the installed formwork for a strip foundation looks like in reality. A layer of waterproofing material (for example, polyethylene film) can be laid in the formwork. The presence of this will prevent moisture from leaving the concrete solution. |

| The calculations indicated how much and what kind of reinforcement should be used for the strip foundation of a particular structure. Follow the recommendations you receive. The reinforcing mesh can be made directly in the formwork (first, vertical rods are installed in 2 rows, then, perpendicular to them, horizontal crossbars, usually having a smaller diameter, are attached) or “on the ground” (then the finished mesh is placed in the formwork). The second option is more convenient to implement, otherwise there are no differences between them. To connect the rods at the intersection points, we use either binding wire or special clamps for reinforcement (a more convenient option). We do not recommend fixing it by welding - this design will last less. Important! The reinforcing mesh cannot be placed directly on the base - it will lead. It is necessary to provide a minimum of 5 cm gap between the pillow and the rods. To do this, we use either stable stones (cheaper) or special clamps-stands (more convenient, simpler and faster). A similar gap must be provided between the reinforcing mesh and the “top” of the fill. Both tapes for external walls and supporting elements for internal partitions are reinforced. |

| If you wish, you can buy the solution ready-made - save time. Helpful advice! Even to build a strip foundation for a compact 3x4 m bathhouse, you will need quite a lot of concrete (calculations were given earlier). It will be quite difficult to quickly prepare it by hand - it is better to worry about buying or at least renting a concrete mixer in advance. We prepare concrete according to the standard recipe: take a share of Portland cement brand M400, add 3 shares of clean fine-grained sand, and add 5 shares of crushed stone. The amount of water is determined by the weight of the cement - the liquid should be approximately half of this figure. At the output we get homogeneous mass medium thickness. |

| We pour the solution into an even horizontal layer, leveling it at the same time with a shovel and piercing it with a reinforcing rod to eliminate excess air (if possible, it is recommended to purchase/rent a special device for this - a deep vibrator). Make sure that the fill is level. After pouring, tap the walls of the formwork with a wooden hammer or block - this will additionally guarantee the correct distribution of the mixture. |

| According to the standard, concrete hardens and gains the required strength within 28 days. Helpful advice! In order for all the cement to react, we spill the pouring surface daily with a relatively small amount of water (this is especially true for the warm season - if there is a lack of liquid, the fill will crack). After spilling water, cover the foundation with polyethylene (it will prevent the sun’s heat from evaporating the water too quickly and will additionally protect the concrete from precipitation). If it is cold outside, we lay a layer of insulation on top of the polyethylene (it is most convenient to use polystyrene foam, it is not afraid of moisture, weighs little and is easy to install/remove). We remove the formwork no earlier than the concrete has hardened (this takes 1-1.5 weeks). In general, professionals recommend leaving the formwork until the concrete reaches full strength. |

Video - DIY strip foundation

Making a columnar foundation for a 3x4 m bathhouse

The structure being arranged can be schematically represented as follows.

We propose to make a columnar foundation using asbestos-cement pipes as formwork. We will fill it with the same solution as the strip structure. For reinforcement we use similar rods. Preparatory activities - from garbage collection to removing the fertile ball of soil - are carried out in the same order. We also do the marking according to the already familiar pattern, with the only difference being that here we mark on the site the places for future installation of pillars: in the corners of each wall and partition, as well as along their length in increments of up to 2 m.

Prices for asbestos cement pipes

asbestos cement pipes

We proceed to arranging a columnar base for a 3x4 m bathhouse, following the provisions of the table below.

Table. Making a columnar foundation

| Work stage | Description |

|---|---|

| Armed with a hand drill with a working “nozzle” of the appropriate diameter (most often, pillars are made with a diameter of either 250 mm or 400 mm, depending on the expected loads on the base), we prepare recesses for future supports. It is recommended to make the holes a couple of centimeters wider than the future pillars (the gaps will later be filled with compacted earth or sand). The pillars are usually raised 200-250 mm above the ground. We select the depth so that the pillars are lowered below the freezing point of the soil by 200-300 mm. Recommendations regarding determining the freezing depth were given earlier. |

| Cover the bottom of each hole with a layer of sand. Recommendations regarding the choice of layer thickness, its alternative composition and compaction remain similar to the provisions for arranging a strip foundation. A log of the appropriate diameter with handles attached to the top for greater ease of operation is perfect for tamping. |

| We assemble the reinforcing frame, focusing on the dimensions of the pillar being installed. Recommendations for choosing the characteristics of the rods, their fastening and the size of the gaps between the bottom and top are the same as for the construction of a strip support structure. Additionally, it is recommended to leave 3-5 cm gaps between the mesh and the walls of the formwork (pipe). An approximate view of the reinforcing structure is shown in the photo. Select the shape of the frame in accordance with the shape of the pipes. We insert the pipes into the recesses and align them vertically, place the reinforcing mesh in the pipes and proceed to the next stage of work. |

| The order is as follows: - pour concrete into the formwork pipe to a height of approximately 5 cm; - we lift the pipe - concrete fills the space under it, due to which an additional supporting platform is formed; - lower the pipe; - pour concrete to full height. We align the pipes vertically by level/plumb. |

| We fill the gaps between the pillars and the walls of the pits with compacted soil/sand. We provide additional stability to the pipes in any suitable way, for example, by installing temporary supports or by covering the pipes closely with massive stones. Let the concrete harden. |

| We lay waterproofing on top of the hardened concrete: - spread a layer of molten bitumen; - lay the roofing material, press and level; - we repeat again. The formwork does not need to be dismantled - it will not interfere. It is recommended to continue construction after the concrete has reached the required strength, i.e. a month later. |

Video - DIY columnar foundation

Video - DIY foundation for a 3x4 bathhouse

We will send the material to you by e-mail

If you have your own plot of land, then one of the objects can be a bathhouse with your own hands. Projects, photos and features of construction work are presented on our website. You can choose any one for construction interesting option or a project from our review.

So, to build a quality building you need to think through the following points:

- choose the ideal project;

- think through each stage of work;

- purchase suitable material;

- plan all communications;

- important point is the interior decoration.

A beautiful bathhouse on the site can be not only a functional building, but also a luxurious element landscape design

To make a bathhouse correctly and correctly choose its location, you need to adhere to all SNiP standards. Important attention should be paid to the material for the construction of the building. The choice of location must take into account certain distances in relation to other objects.

Before building a bathhouse, take into account the characteristics of the site: design, climatic conditions and soil characteristics, local features landscape territory and soil properties. If the territory is uneven, then it is better to carry out construction on an elevated area, since this will ensure optimal water flow. You should not install such a building on sandy soil. In any case, the foundation should be strengthened. The harder the soil layer, the better. Most often, the construction of such buildings is planned on the leeward side of the main buildings. This placement protects from heavy rainfall.

- Budget wood concrete is also often used. At the same time, the building turns out to be warm and durable.

Bathhouse made of timber

How to build such buildings depends on the material options. Projects can be made from the following materials:

- natural wood;

- edged timber;

- glued timber;

- profiled timber;

- rounded logs.

There are several ways to build a sauna with your own hands. A simple option can be seen in the video:

Most often, construction is carried out using rounded logs and timber. A timber bathhouse is a simpler option than rounded logs. is a cheaper material than logs. Construction from timber is carried out using.

When deciding how to make a building from timber, you must follow some rules. This kind of construction refers to lightweight buildings, so you can use a shallow or non-buried foundation.

How and what kind of foundation to make depends on the type of soil. The columnar option is not suitable for clayey and swampy soil. In this case, or are used.

Before deciding how to lay the timber, it is necessary to carry out waterproofing. To do this, a layer is distributed on the surface of the foundation, and a sheet of roofing material is placed on top. Then the second layer is applied. And the boards adjacent to the foundation are processed antiseptic solutions. This is how we build a bathhouse, no matter how small or large it is. A common option for construction work is a small bathhouse made of half-beams.

When deciding how to build a sauna yourself, you must first choose high-quality wood. The material is most often harvested from December to March. Blanks 150×150 or 100×150 are made from felled trees. At the same time, they must be cleared of bark. It is important to inspect the material before construction work. There should be no signs of rotting or cracks. The wood should be smooth and even. When choosing beams, drawings and dimensions must be prepared in advance. In this case, the purpose of the material is important, for example, a floor made of edged boards. At self-construction you need to know how it's done step by step construction and methods for joining 3x4 or 4x4 logs.

It is important to know how to install 50x150 boards on edge, as well as options for increasing the length. There are such connection options as in the paw and in the head. For a structure made of profiled timber, the burl method is suitable, in which the connection is made when creating key grooves.

Frame bathhouse in the country

Consider a variety of projects for . The walls are lattice structures. For the walls you will need:

How to build such a structure depends on the main project. This construction technology has many advantages. This is a high installation speed and low labor intensity. According to reviews, this is an economical construction. The finished building is characterized by rapid heating of the premises. A mini sauna or even a 4x6 or 6x6 design does not require long-term shrinkage. There is also big choice materials for both interior and exterior decoration. Can be used different option s foundation, for example strip or on piles.

How to make such a design is demonstrated by a photo report, where the photo shows detailed diagram and features of the construction of such buildings. Such structures also have certain disadvantages. First of all, careful thermal insulation of such structures is required. Also, such structures have a short service life. Depending on the projects: 3x4, 2x4 or 3x5, drawings are selected. The finished project must contain working drawings with the correct assembly of the structure, with utilities and specifications of materials.

We build a bathhouse with our own hands: a brief description of the construction stages

Any construction of a bathhouse in a country house requires careful planning. Before construction begins, it is necessary to mark the site. To do this, you will need a project, according to which marks on the ground are made. Where to start marking the dimensions depends on where the corner of the building is located. This place is where reporting is done from scratch. At the same time, a peg is driven in, and the lengths of the sides are measured from it. Then compact pegs are installed and other walls are also measured.

The design of the bathhouse and dimensions are indicated in accordance with the project data. After this, the marking is made depending on. When building a bathhouse with your own hands from stone, brick or blocks, you need to level the foundation. At the same time, roofing material is laid, and then roofing material is placed on top.

How to build a building will depend on what material it will be built from - from boards or from. Specialists can show you the installation features. Useful videos can be found on YouTube.

If used brickwork, it should start from the corners. In this case, the first blocks are placed on the cement mortar. They must be located in the same plane. If you don't know how to do it correctly, use string as a guide.

In the video below you can see a step-by-step demonstration of construction work:

After installing the jumpers over the windows or doors, an armored belt is mounted and then made. The foundation bolts are attached to this part. Simple or panel structure involves the construction of a frame made of wood. This element is sheathed and insulated with various types of finishing materials. To make the frame, boards made of aspen, linden or larch are used, since these options are characterized by low.

The wooden frame made from timber is made on the foundation. In this case, cuts are made at the ends of the bars and fastened to each other with self-tapping screws. For small bars, metal corners are used.

Let us note the main stages of manufacturing a frame base:

Any sauna is subject to high humidity, so the steam room is treated with a vapor barrier film. This will protect against moisture accumulation from the inside. As thermal insulation material fiberglass or mineral wool. Such options provide an excellent level of sealing. Insulation and wall covering are carried out after the roof is installed. This approach will protect the wood and insulating materials from getting wet.

Particular attention should be paid. Before choosing equipment for a bath, you must completely complete construction works. The finished building is equipped with furniture and all necessary equipment. A country bath can be made from various materials, but not from slab.

Do-it-yourself bathhouse foundation: step-by-step instructions

How to build a bathhouse depends on the type of foundation used. It is worth noting the following options:

- slab foundations are not performed often. It is suitable for massive and complex buildings. The markings are made according to the dimensions of the building or slightly larger;

- You can make a strip foundation for a 4x4 sauna with your own hands. In this case, the marking is done so that the tape runs along the perimeter of the building;

- columnar is used for the installation of wooden buildings. Depending on the dimensions 3×4, 3×5 or 3×6, markings are made according to the number of supports;

- . The advantage of this option is the ease of installation. With its help, it is possible to install it on a foundation even on a sloping site. Marking is carried out according to the number of piles.

It is even possible to build without a foundation. A shallow strip foundation can be used when the soil is hard and dry, the groundwater level is low and the buildings are not very heavy. The shallow version is the simplest. Here are the main points to consider:

How to install a screw foundation can be seen in the video below:

Bathhouse with shower in the country: how to supply and drain water

Exist different ways How to arrange a shower inside a bathhouse with your own hands. There is even a special step-by-step guide. The photo report demonstrates different shower installation options. The easiest option for cooling is to mount a simple wooden bucket on the wall. Water can be poured into it through water pipe with tap. In this case, no special heating is required. In the photo below you can see a shower with hydromassage jets. In this case, it is necessary to consider water heating, as well as pressure using pumping equipment.

A shower does not require a large area; it is enough to allocate some space in the dressing room. Necessarily . It is necessary to install a drain for the bathhouse. You can also make inside the bathhouse Summer shower. In this case, there is no need to set up a separate cabin in the yard. Even in an already constructed building you can find a corner for a washing room. But this will require constructing a drain in the bathhouse.

Instructions for building a bathhouse roof with your own hands

When building a bathhouse, you need to figure out how to install the roof. The stages of such construction can be seen below:

Options for creating a roof may be different, but in any case you need to think about waterproofing and thermal insulation. Without waterproofing, steam will travel into the attic and settle on the rafters and beams. In this case, condensation may drain onto the insulation, which will affect the durability of the material. It is important to take into account some features of buildings:

Organization of internal equipment for a bathhouse in the country

An important point is the arrangement of the internal environment. A variety of interior photos will help you decide how to design the interior. Any projects should start with installation. This design will reduce the concentration of hot air.

After construction is completed, it is also done outside with your own hands. Another important point is. If there is insufficient ventilation, electric heating will cause a decrease in oxygen levels.

We must remember to constantly monitor temperature regime. Do not install a mercury thermometer. Better buy a bath thermometer. To control humidity, use -.

Special attention deserves interior decoration. The most suitable material is wood. A good solution and an economical option is lining. Wall decoration should be done in pastel colors. It is worth considering the floor in the bathhouse.

Step-by-step instructions include stages finishing works, as well as lighting and ventilation layout. must be of high quality. Also think about bath accessories. Step by step guide also provides for good sound insulation.

Article

It is much easier and faster to build a frame bathhouse than a brick or log house. Large-scale drawings, expensive materials and work, an impressive foundation - all this is missing. The main thing is proper thermal and waterproofing, as well as a ready-made project that you can focus on.

A strip or column foundation is sufficient for such a building. The structure practically does not shrink due to its lightness, so for the base of a small frame bath you need to purchase only well-dried timber measuring 20x20 cm for the racks and a board. Drawings of the most simple and low-cost baths can be seen below.

The advantages of frame baths also include the absence of deformation, the ability to make utility lines hidden, and a variety of finishing materials. A building with a square area of 12 m2 also retains heat perfectly, like a log house.

To ensure that your bathhouse lasts a long time and does not require repairs, you need to pay attention to the following points:

- the frame must be located on a flat surface;

- you should not choose the cheapest thermal insulation;

- the wood must be of high quality, not thin and carefully treated with antiseptics;

- if the frame is in doubt about its instability, it must be strengthened with struts.

Frame baths are not afraid of shrinkage, since the material is quite elastic and is not afraid of shrinkage. The upper sections of the base rest on supporting, well-waterproofed beams. It is better if they are made of oak, larch or hornbeam. To connect the wooden belt and the foundation, I use anchors made of reinforcement (1.4-1.6 cm) with hooks buried in concrete up to 20 cm. On the other side there should be threads for a nut.

Corner joints, as a rule, are made “under the paw” and secured with anchors. Next, the outer racks (10x15 cm) are placed vertically and secured using jibs. The thickness of the racks should correspond to the thickness of the insulation.

For buildings 3x4 m, it is permissible to install struts on corner posts.

If the bathhouse is two-story, it is better to install struts in each span. The pitch of the frame posts is 0.6-0.8 m. They are attached to the support beam using steel brackets. The beams must have a cross-section of at least 5x15 cm.

Features of building a frame bath

A frame bathhouse will last quite a long time if high-quality and reliable thermal and waterproofing is used. The outside of the building can be protected from external influence siding or blockhouse, which will make the bathhouse look like a log house and protect it from rot or mold.

In fact, it is quite possible to equip a mini-bath yourself. No special skills are required. The main thing is to imagine how it should look (with or without a terrace), think about ergonomic heating and drainage, thermal insulation and familiarize yourself with typical options. Photos of 3x4 frame bathhouse projects with your own hands can be seen below.

The finished project is small bathhouse building You can order from a number of companies, however, in order not to be disappointed in the end and, if desired, you can do everything yourself. First, you need to lay a foundation, which means purchasing asbestos-cement pipes up to 40 m long and with a diameter of at least 10 cm. You also need to drill a well - diameter - 20 cm, depth - 1.5 m. And, prepare a solution of water and small crushed stone , cement and sand.

An important step in building a bathhouse with your own hands is strapping, which requires 5x10 cm boards treated with antiseptic solutions. The walls are marked and the material is laid along the outer contour. The board is laid with its outer edges and fastened with nails. The base is connected using supports.

The straps (upper, lower) are made of boards, the roofing felt flooring is cut off from the lower surface. I control all work carried out by level. If there is a deviation, additional installation of roofing felt is carried out. In order for the structure to be strong, the strapping and logs are secured using pre-installed metal plates. They also need to be treated with an antiseptic.

The construction of walls requires measuring the footage between the axes. If there is no connection with the walls, 0.6 m is enough; if they are present, a gap of 0.4 m is required.

Post-to-post spacing will vary depending on dimensions window openings and doors. The frames, after fastening, must be checked for exact coincidence with the rectangular parameters. It is better to assemble rafter structures on open area land. The roof is provided with ventilation system. To give the structure rigidity, the walls are covered with plaster shingles.