The need for a garage is not discussed if you already have a car. In most cases, the car owner tries to provide for his vehicle the safest refuge. But it happens that circumstances favor the need to build a garage with minimal costs and as quickly as possible. Is this really real? This will be discussed in the article.

Preliminary stage

Doing it cheap does not mean doing it poorly. Although different materials can be used to build a garage, preliminary stage will be the same for each of them.

Selecting a location

The convenience of using it will depend on how well and correctly the location for the garage is selected. If there is no other way out, then you can start from the free area in the yard. If possible, it is best to place the garage closer to the main building. In this case, it will be easier to operate it in bad weather, since you will not have to travel long distances, for example, in a downpour. If circumstances allow, then you can build a small transitional canopy for these purposes. It is good to place the garage structure in line with the main gate. If you are planning a parking area in front of the garage, then you need to step back five meters from the main gate. This will ensure that even with a parked car it will be possible to open the gate.

The site on which the garage will be built should not be the lowest point on the site. If this is the case, then rain and melt water will certainly accumulate inside the room, which is not good for both the car and the tool that is in the garage. This is also bad for most building materials from which the garage will be built. When servicing a car, you will definitely need water and electricity, so it is necessary to locate the garage in such a way that you have to put in less effort when connecting communications.

Laying the foundation

The optimal solution when constructing a garage structure at the lowest cost would be a slab foundation. A foundation of this type can hardly be called the cheapest solution, but it will eliminate the need for subsequent pouring of the screed. In the selected area, the dimensions of the future structure are clearly indicated. This can be done with string or fishing line stretched between the pegs. After this, the turf is removed from the designated area. This will make it possible to simplify the task of soil sampling. Next, a pit is dug over the entire area of the structure. Its depth should be half a meter. If it is known that the soil in the area is very frozen and heaving is observed, then additional insulation will be required.

The bottom of the pit for the garage structure is leveled and compacted well. After this, sand is added, which is also well compacted and leveled. A layer of 10 cm will be enough. A backfill of medium-fraction crushed stone is made of the same thickness; it is also leveled and compacted, which will simplify the task of subsequent filling. If insulation is necessary, insulation in the form of extruded high-density polystyrene foam is laid on top of the crushed stone. The one used for insulating routes is suitable.

The next step is to construct a metal grate. For a pouring height of 15 cm, one level of the grid will be sufficient, which is laid out with a cell of 10 cm. The metal rods are tied together using knitting wire. The dimensions of the grate itself should be 5 cm shorter on each side compared to the overall size of the foundation for the garage. The metal structure should not be laid directly on insulation or on crushed stone. It should be raised by 5 cm. This can be achieved with special plastic stands, which are commercially available for these purposes.

The final stage in forming the foundation of the structure is pouring the concrete solution. It is better to use a concrete mixer for its preparation, since it will provide sufficient pouring speed to make the slab monolithic. After pouring, a deep vibrator is used. Its task is to correctly distribute the solution over the prepared base structure while removing air from the thickness. Smoothing can be done with a large trowel. Further work construction of the structure can begin in two weeks, if we are talking about the warm season.

Advice! If groundwater are close to the surface, then the foundation is waterproofed. For these purposes, waterproofing material is placed under the insulation.

Possible options

The most affordable materials for constructing a garage structure at the lowest cost can be considered wood, corrugated board and cinder block. Each garage option has its own nuances that are important to consider during construction.

Wood

The simplest version of a wooden structure can be considered a garage built using frame technology. Without much difficulty, the entire structure can be built independently. In this case, a pitched roof is used, which requires a simplified rafter system. The basis will be a square beam with a cross-section of 10 cm. The first step is to waterproof the surface of the foundation under bottom trim. The latter is made by laying logs around the perimeter of the foundation. The logs are securely fixed to the surface of the structure using anchor bolts. It is possible to provide special metal plates, which are embedded in the foundation and subsequently act as log holders.

After the bottom trim of the garage has been completed, vertical posts are installed. Corner ones are made from the same timber. It is important that they are positioned vertically and secured with jibs. Along the upper edge of the structure, the top trim is made with the same beam. At a distance of 60 cm, additional vertical posts are installed on each of the walls, except for the one where the entry gate will be located. A window and door opening is provided, which, along with the opening for the gate, is reinforced with additional racks. Rafters are laid across the entire length of the garage structure, onto which the roof will be fixed.

Advice! To create a garage roof slope in the required direction, it is necessary to provide in advance that two of the four side posts are longer.

A sheathing is made on top of the rafters for a specific type of roof for the garage structure and the finishing flooring is installed. The walls are sewn up with any suitable material. For the garage you can use moisture-resistant OSB plate, which is subsequently painted in the required color or coated decorative plaster. We are installing windows, doors and garage gates. Below in the video you can clearly see how a garage of this type is built.

cinder block

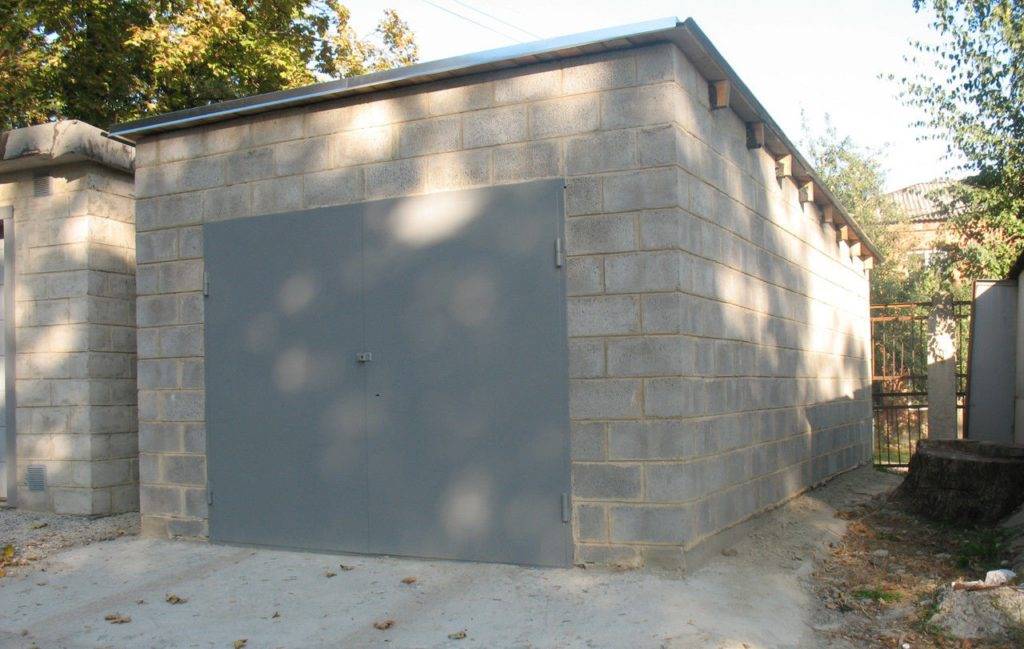

The second material option that can be used to build an inexpensive garage is cinder block. It consists of blocks made from a solution that is mixed with slag, which is a by-product of any production. The cost of a cinder block is low, but you can build a good-quality garage from it. After waterproofing the foundation, construction of the walls of the structure begins. Laying cinder block is carried out in the same way as brick. But in this case it is necessary to try to make minimal mortar joints.

After the garage walls are ready, you can proceed to the construction rafter system. A Mauerlat is mounted on the upper edge of the garage walls, which can be made of wood or poured in the form of a monolithic armored belt. The reinforcing structural element allows you to reduce the load on the walls and securely fix the garage roof. In this case it is also more convenient to use pitched roof, which will save on wood for farms. According to the requirements of the roofing decking manufacturer, the sheathing and finishing sheeting are installed.

The final stage is the installation of gates, doors and windows. Cinder block cannot be left without external finishing, as it absorbs moisture well and can be destroyed over time. To prevent this from happening, the surface of the garage walls can be plastered or covered with siding. The second option will be implemented in more short time and will cost less. Video about finished project There is a garage of this type below.

Corrugated sheet

Another option for an inexpensive garage is a structure made of corrugated sheets. In this case it is best to use metal carcass, which will serve as the basis of the entire structure. Before laying the foundation of the structure, it is necessary to install support pillars. They are installed every two meters. A metal pipe measuring 8x8 cm can be used as garage posts. A hole is made under each post using a garden drill. It must go below the freezing point of the soil, so that when the top layer freezes, the frame does not lose its geometry due to exposure to heaving soil.

After the supports of the garage structure have been walled up and the foundation has been poured, the top frame of the structure is completed with a profile of the same size. The entire structure is further strengthened by jumpers made of square pipes measuring 4x6 cm. The number of elements will depend on the height of the garage and the number of sheets that will be used to construct the structure. The next stage is the assembly of roof trusses. It is better to paint each structural element on the ground, since later you will have to spend more time if you paint them in place. The trusses are lifted and welded to the top frame. The sheathing under the roof deck is installed on the trusses and the roof is laid.

The next step is to cover the garage walls with corrugated sheets. This is done by using special roofing screws or rivets. If the presence of windows is provided, then openings for them can be cut after the garage has been sheathed. But mortgages for windows in the garage must be provided in advance. Simultaneously with the sheathing, the roofing decking is laid. The last step is the installation of gates and doors, as well as wiring electrical network around the garage. A similar garage design is described in the video below.

Summary

As you can see, a cheap building can be erected quite quickly and from materials that are available in almost every area. It is worth remembering that when constructing a garage structure from corrugated sheets, you can use wall option. It has a lower cost than roofing, but when placed on the wall it is not inferior in strength. A strip foundation can be constructed for a cinder block structure. To do this, you will have to deepen it below the freezing level so that it maintains its integrity. Inside the room, a screed is subsequently poured, the thickness of which must be at least 5 cm in order to withstand the weight of a passenger car.

Brick is expensive, but lately it has not been in demand, and not only because of its high cost. Yes, the brick looks beautiful and has excellent characteristics, but construction takes too much time. Another thing - alternative materials:

Here are the three main building materials used frugal builders. Let's explore the detailed technologies building a garage cheaply and reliably.

Made from wood

Perhaps, wood- this is the most best option, because here, like no other option, external aesthetics, environmental friendliness, efficiency and ease of construction are successfully combined. But working with wood also has its own nuances.

Please note that there are two construction methods: from rounded logs And frame technology . The first is more reliable, the second is cheaper. Choose the option that suits you best.

Technology

How to build a garage cheaply with your own hands from wood? Preparatory stage consists in choosing the location of the future building and its model. Garages can be free-standing or attached to a building. The types of gate openings are also multivariate. All these points should be decided in advance.

After drawing up the plan and layout, the construction site is leveled, cleared, and compacted. The site must be perfectly flat so that there are no kinks or distortions afterwards.

The site is ready, it’s time to begin the most important part of our construction - pouring the foundation. Along the perimeter of the future building, a trench is dug on which the formwork is installed. A must do pillow from several layers of sand and gravel, which is carefully compacted.

The base is reinforced with metal rods and filled with concrete. Now we need to let the foundation stand at least three weeks. When the foundation is ready, we proceed to the lower trim, which is made from the board 50x100 mm.

ATTENTION: Don't forget about wood's tendency to absorb moisture and rot. Therefore, process in advance construction boards antiseptic.

For corner posts and gate leaves it is best to take timber, while other frame elements are made of boards 50x100 mm. When performing the lower trim, maintain an interval of no more than 120 cm.

Also, if you want your garage to be as durable, strong, solid and last a long time as possible, install braces in the corners. This will give the structure greater stability.

The hardest part of the job is pouring the foundation And erection of the frame. For the frame you need stronger, thicker boards, while for the arrangement you can use a 25x100 mm board; even simple lining will do here. The board is then covered with any finishing material, after which it is necessary to carry out hydro- and vapor barriers by laying several layers of polyethylene or polypropylene film.

As you can see, the garage is the cheapest made of wood not that difficult to build.

Photo of the garage made of wood:

cinder block

Second most popular building material for the garage is cinder block. Today, cinder blocks come in several types:

- made from blast furnace slag, which is famous for its excellent performance and durability;

- shell rock;

- brick fight.

To improve performance, some manufacturers add more perlite, polystyrene and other materials.

Everyone loves a cinder block, but there's one in it. flaw: like a tree, he absorbs moisture, which is why it quickly collapses. In dry soil, this quality of material will not be problematic, and with proper construction it will last up to fifty years, but in places where there are groundwater, it is better to choose another material, because if the wood can still be treated with varnish, you can carry out such manipulations with a cinder block it is forbidden.

ATTENTION: You need to know that cinder blocks are divided into types not only by composition, but also by configuration: hollow, which are used for walls, and solid, intended for the foundation. Ignoring this feature can lead to rapid destruction of the entire structure.

Technology

In the construction of a garage from cinder block, we also conduct preparatory work, clearing and leveling the site, developing a plan for the future structure.

A poured foundation is ideal for wood, but cinder blocks do not need such powerful support; this will work here. The strip foundation is made as follows: the top layer of soil is removed and a trench is dug about 45-50 cm deep and 40-45 cm wide. Then a cushion is made of sand and broken brick, which is then filled with cement.

You can do it another way: the trench is filled with sand and then filled with water. The combination of water and sand gives the structure strength and makes it resistant to time and changes in temperature and humidity. After this, reinforcement is laid at the bottom and the entire structure is concreted.

In a month you can begin construction of the walls. Third construction method strip foundation even simpler: instead of sand, rubble stone is poured into the trench and the entire structure is filled with cement grout, not lower than grade 150.

After the foundation is erected, the base is equipped with heat and vapor barrier materials. The most universal option hydro-, heat- and vapor barrier is simple roofing felt.

- walling;

- floor screed;

- roofing;

- hanging the gate.

Cinder block laying identical with bricklaying, only here this work is carried out several times faster. Laying can be carried out in half a stone (spoon method) or in one stone (poke method).

Masonry of 2 and 1.5 stones is also practiced. You choose the option that suits you, remembering that the thickness of the walls directly affects the durability of the garage and its ability to withstand sudden temperature changes. A garage of one stone will freeze in winter, even if several heaters are installed in it, while one and a half and two stones will be warm and cozy.

When erecting walls, you should first lay out corners, and only then, stretching construction cords between them, begin laying blocks brick method, that is, overlapping the seam of the previous row.

When constructing a floor, remember that the screed must be not less than 10 cm. Concrete is good for screeding M200, which is poured in several layers and then, after drying, rubbed over.

The final stage – electrification And interior decoration

.

Photo of the garage from cinder blocks:

Corrugated sheet

What's the easiest way to build a garage? A universal material is suitable for this. corrugated sheet. It is perfect for fences, for sheds, and also makes good garages. But the most important condition here is the competent choice of corrugated sheeting: for the construction of a cheaper garage, only brand PS or WITH.

The corrugated sheet is marked with a letter and a number. Letter "WITH" stands for "purpose for walls", number – sheet stiffness. The higher the number, the stronger the sheet. S-20– the most optimal option for construction.

Sometimes sellers, due to their illiteracy or when there is no twenty in stock, recommend a ten or an eight for construction, but! Never fall for this sales trick! A garage made of such a sheet, although it will cost much less, will not last long, and in winter it will be icy, and it will be impossible to warm it up. And the wind will make the walls shake. You need it? We think not, so we stick to the standard one. twenty.

Ideal flooring thickness: half a millimeter.

Technology

How to build cheap garage with your own hands from corrugated sheets? We will need:

- reinforcement and concrete for foundation construction;

- elements for the frame: corner, bars, metal rods;

- metal elements for gates;

- self-tapping screws

Arm yourself with the following tool:

- screwdriver;

- welding machine;

- Bulgarian;

- metal scissors;

- jigsaw

Photo of the garage from corrugated sheets:

Let's get to work. First of all, fill it in. Having cut off half a meter of soil, fill the resulting trench with sand and fill it with water. Wells are made for frame racks, which will also become foundation racks.

This work will help make the foundation stronger and more resistant to ground movement. The wells are driven to a depth of at least half a meter.

The following is all according to the standard: A wooden formwork is erected, onto which the reinforcement bars are installed. For strength, the rods are secured with wire. Now the main thing is not to forget to install frame structure racks in the wells.

IMPORTANT: Before installing the racks, it is necessary to process bitumen underground part of the structure.

To prevent the racks from becoming warped, they are carefully aligned using level. Final stage work – pouring concrete into reinforcement. Use mark 300, for this case, this is the ideal option.

Some builders claim that construction can be done within two or three days after pouring concrete, but professionals still advise waiting until the required time. three weeks, otherwise the foundation may crack, and then it will no longer be possible to correct the mistake. Patience and more patience is the key to success.

When the foundation is ready, they build metal carcass. Both welding and a grinder with a jigsaw for cutting metal pipes will come in handy here. the right size, and some more welding skills. With basic welding skills, the frame can be welded in a day or two. It takes a newbie a week. In order to make a frame, you need to carefully study the drawing several times and cut the material according to its data.

Using welding, we weld horizontal metal rods to the racks. Welding is underway at three points. If the frame is made of timber, then in addition to everything, special fastenings for wooden crossbars are welded to the racks. The bars are attached using self-tapping screws.

Now the corrugated sheet is attached self-tapping screws. You can adjust the sheets to size using a jigsaw. It's better to do this job team of three or four people, it is almost impossible to cope with it alone.

When the frame is completed, the gate installation stage begins. Here you also need to show patience and maximum attention to avoid mistakes. The gate frame is made from metal corners and sheathed with corrugated sheets. This work can be completed in a day or two.

As a rule, it is performed in a single-pitch version. The roof frame is made of crossbars (wooden or metal), onto which a clapboard sheathing is attached. It is important to take into account the climatic features of your region.

In the southern regions, a lightweight sheathing design can be used. In the northern ones, where winter period with blizzards and snow drifts is quite long, it is better to make a stronger, high-quality structure that can withstand a load of snow.

We described the main stages of construction technology. Now it's your turn to choose from what cheaper build a garage with your own hands for your swallow. And all we can do is wish you good luck and peaceful skies above your head!

Useful video

How to correctly lay cinder blocks during construction budget garage, watch the video:

A car needs a separate room where the car will be safe from thieves and weather conditions. You can build a garage from different materials, the choice of which will determine the cost of the structure and the time for its construction. The project is selected taking into account your own budget and skills construction work. To decide how to build a garage cheaply and quickly, consider available materials and simple designs.

Construction technology divides garages into two main types: capital and light. Substantial structures have a solid solid foundation and stone walls. Lightweight structures are made on a strip or slab base, and the material for them is corrugated sheeting and sandwich panels.

Placement of the building

- On a small plot of land, a built-in garage is being designed, located on the ground floor. It does not require the construction of a separate foundation; the ceiling of the first floor is the roof. The main difficulty will be to ensure reliable waterproofing and protection of the house from exhaust gases.

- The home extension option provides a ready-made wall. It is easier to make a common roof than two separate ones, and heating does not have to be carried out far. But such a neighborhood is not very convenient, so it is better to connect the garage with outbuildings.

- It is better to place a separate structure for a car right next to the fence, so as not to lay a driveway along the site.

A quick and inexpensive construction of a garage for a car is made from cinder block or foam block. Latest material It is relatively light and inexpensive, and thanks to its significant dimensions, the construction process is accelerated. It’s easy to build a foam block garage with your own hands. For foundations on heaving soil it is worth using monolithic slab, and normal soil makes it possible to install a shallow strip foundation.

The blocks are laid using special glue or a solution of sand and cement. Before the construction of the walls begins, a metal frame for the gate is installed. Laying the blocks starts from the corner and is tied together. Masonry requires the installation of reinforcing belts. Due to the hygroscopicity of the material, the garage requires external finishing. The walls are plastered, covered with facade paint or siding is used. The roof is made of a single or gable roof, beams and boards are used for the rafters, and slate or corrugated sheets are used as the roofing. Ventilation is required in the garage; for profitability, you can use natural system. Two holes are made on opposite walls - one at the bottom, the second at the top. The dampers installed on them will allow you to control the air flow.

Until recently, lightweight and prefabricated buildings consisted of a frame and smooth steel sheets. Now corrugated sheeting is used to cover the garage. The material is not inferior in characteristics to siding, but has affordable price. The building can be used for up to 40 years. The large area of the sheets and the simple process of attaching them to the frame with self-tapping screws occurs quickly and does not require professional knowledge.

When laying the foundation under the garage, fasten metal pipes for the frame. A strip foundation is made; if an inspection hole is planned, it is dug out and concreted at the same stage. The remaining parts of the structure are attached to the walled pipes. If you don't know how to use welding machine, then a bolted connection is used. The pitch of the vertical posts depends on the operating conditions; if insulation is planned, it must correspond to the width of the mineral wool strip. If mineral wool is purchased in wide rolls, then they are cut in half.

Wall profile sheets are fastened vertically with self-tapping screws with a rubber gasket. The roof is made gable and covered with corrugated sheeting. The sheets are placed with an overlap of at least 20 cm, the joints are sealed with sealant. Fastening is carried out sequentially in each wave. The edges of the covering should hang down by 40 cm to prevent water from flowing down the walls. Before insulating the room, all cracks are blown in polyurethane foam, then insulation is laid on the walls and ceiling. Mineral wool covered with plywood or other wood-based boards. The floor is poured with concrete screed. As a result, in a few days you have a cheap garage .

Construction using sandwich panels

The use of sandwich panels allows you to create a structure ready for use; no additional external or internal finishing is required. The panel consists of two layers of metal separated by insulation. For a garage, it is enough to make a strip foundation and pour the floors concrete screed. You can build on concrete base, then a mesh of reinforcement with a diameter of 8 mm is laid under the finishing coating with the solution.

The walls are assembled from metal profile, diagonal elements are made for rigidity. Additional ribs are placed at a distance of 50 cm. The side and rear walls are assembled according to the diagram, and a place for the gate is marked on the front. To install the roof you need a profile bigger size to withstand high loads. The finished frame is connected with special fasteners. Sandwich panels for the walls are installed first, they are fastened together lock connection, but you should coat it with sealant. After covering the walls, the panels are laid on the roof.

You can make a garage without investing a significant amount; any of the presented methods is presented in the video.

Video

This video is about building a metal garage. You will see how the metal structure was assembled in a day and a half:

Photo

This collection of photos shows inexpensive garages that you can do yourself.

A garage on the property gives the owner a lot of advantages. No need to think about where to park your car. The car is safe at any time of the year. The garage is constructed from the following materials. Suitable timber, foam blocks, cinder blocks, stone, brick or finished metal structure. If you carry out the construction of a garage yourself, you will be able to avoid large expenses, saving on the labor costs of professional builders.

What is needed to build a garage

- Select building materials.

- Find a suitable location.

- Develop a project.

- Make a layout of the future object on the site.

- Carry out excavation work.

- Pour the foundation.

- Arrange the basement.

- Install gates.

- Build walls.

- Build floors.

- Cover the roof.

- Make a floor and blind area.

- Complete the interior decoration.

Selecting a location

- Take general plan plot.

- Look at how residential and outbuildings are located.

- Choose a place that is allocated for the construction of a garage, observing fire safety regulations.

- Pay attention to how the future building is located in relation to the house.

- Note the ease of entry and exit.

Three options for the location of the garage on the site:

- In the depths of the site.

- On the line of the external fence of the site.

- On the border line between two areas.

In the first option there is freedom of action. You just need to take into account that the distance from the residential building to the garage is at least 9 meters. If there are buildings with plastic finishing on the site, the distance to them is at least 15 meters.

In the second option, you need to pay attention to ensure that the opening garage doors do not interfere with the movement of cars or people. Therefore, the distance to the fence of the site is at least a meter.

The third option imposes the following distance restrictions: at least a meter to the border of the neighboring plot. At least 10 meters to the windows of the neighboring house.

The size of the building depends on the size of the car and the number of cars. If you are building a garage for one standard car, its dimensions are as follows:

- length – 6 meters;

- width – 3.3 meters;

- height – 2.4 meters.

For a car longer than a standard one, you will need a garage up to 7.8 meters in length.

Two car garage size:

- length – 6 (7.8) meters;

- width – 6 meters;

- height – 2.4 meters.

Development of a garage project

When developing a project, you can use two options:

- Order technical documentation from specialists.

- Make a plan yourself.

With the first option, you won’t be able to save money; a lot of time will be spent waiting, but the result is guaranteed.

The second option, if you can afford it, does not require costs or a long time. Mentally imagine the future structure and draw its diagram.

Please note the following points:

- location of the building;

- dimensions;

- the presence of an inspection hole;

- building material used;

- capital construction, or installation of a finished structure.

Georeferencing

When the plan is ready, you need to lay out the structure on the site. The plan is transferred to real soil. To do this, mark the corners of the future structure with marking stakes or reinforcement on the ground.

- Drive one peg in first.

- Then from it, using a square and a tape measure, measure the remaining three.

- Stretch a rope between the stakes.

- Start excavation work.

Do-it-yourself garage foundation

During the excavation work, a trench is dug to fill the strip foundation. Trench width – 40 cm, depth – from 60 cm to 1 m, depending on the degree of soil freezing in your area winter time. The bottom of the finished trench is trampled down, the walls are processed vertically with a shovel so that the earth does not crumble.

It is better to make a rubble concrete foundation; you can save on cement by using rubble crushed stone.

Place large fractions of crushed stone or stone in rows at the bottom of the trench. Spill each row cement-sand mortar until the trench is filled. To prevent the foundation from shrinking, use cement good quality, and add no more than 2 parts of sand to 1 part of cement. Water usually leaves according to the amount of cement.

If you plan to install a ready-made metal structure, it is necessary to fill the entire area under the garage with concrete.

Basement and walls

IN capital construction After pouring the strip foundation, install plank formwork around the perimeter of the trench. Use a level. Fill the base with concrete. When the concrete has dried, lay roofing felt waterproofing in two layers. Install gates before building walls. The gates must be special garage doors made of metal. They must be fixed in the masonry (stone, brick, block).

After installing the gate, begin laying out the walls. Start laying from the corners. Stretch a cord between the corners, along which you carry out the laying in rows. Use a building level and check yourself with a plumb line.

Ceilings and roof

The ceilings of a permanent garage are also its roof. The difference in the height of the ceilings will provide the necessary slope of the roof for water drainage. The roof slope is 5 cm per meter.

The ceilings are made of steel beams with a laying step of 80 cm. Sew them up with boards, lay roofing felt, pour slag, sand or expanded clay, make cement screed. After the cement has dried, cover the roof with waterproof material.

Floor and blind area

The garage floor must be concrete. Level the base of the floor, compact it, cover it with sand or crushed stone in a layer of 15-20 cm. Fill it with a concrete screed. Outside, along the perimeter, arrange a blind area at least 50 cm wide. The blind area is made at a slope to drain rainwater.

The interior arrangement of the garage, the decoration of walls, floors, the availability of lighting, heating depends on the wishes of the owner. The garage can accommodate not only a car, but also various tools and equipment. You can use the garage as a workshop. Many people make a basement or cellar in the garage.

How to build a garage with your own hands (video)

See how to build frame garage with your own hands

Bottom line

It is very possible to build a garage yourself. Just remember to carefully prepare the project and choose quality materials. In this case, the fruits of your labor will make you proud of your work.

Many city residents try to go to their dachas in the summer to relax and breathe fresh air, and at the same time work on the land. Besides garden house on summer cottage It is advisable to have a garage that houses not only a car, but also various garden tools, equipment, power tools. Many summer residents use this room as a workshop, placing machines and other equipment near the walls. As they say, if only there was a garage, a thrifty owner will always find a use for it. You can build a garage at your dacha with your own hands from different materials: timber, brick, foam blocks, cinder blocks, etc. When you carry out construction work yourself, you can reduce the cost of the structure, saving a lot on paying for the services of a team of builders. A person with little experience in construction and free time can cope with this task. The process will speed up significantly if you call a few friends for help.

The garage can be wooden, metal or stone. Metal garages collected very quickly from ready-made kit, although this will require the help of an experienced welder. Such structures require additional insulation if they are planned to be used in winter. The most common are garages made of stone materials:

- bricks;

- gas silicate blocks (gas blocks);

- foam concrete blocks (foam blocks);

- cinder blocks (cinder blocks).

Stone buildings are the most reliable, which is why they are called capital buildings.

Stylish wooden garage, built on a summer cottage with your own hands, can fit perfectly into the overall design of a suburban area

A metal garage, purchased in disassembled form, is assembled in a few days at a summer cottage with active participation experienced welder

Main stages of garage construction

Any construction requires preparation, during which a project of the facility is developed, everything is purchased necessary materials, excavation works are being carried out and further down the list. Let's consider each stage separately.

First stage: development of the project in a simplified form

Before building a garage for a summer residence, you need to mentally imagine the future structure and draw a small project diagram on a piece of paper. Of course, you can order technical documentation from professional designers, but then you will have to forget about savings, since the services of these specialists are not cheap. A garage is not a work of architecture, so you can design this object yourself. At the same time, decide on the answers to a number of questions:

- For what purpose is a garage being built? Just to provide a parking space for the car? If you plan to repair and maintain a machine, is an inspection hole necessary? Do you need a cellar? Write down all your wishes on a piece of paper and take them into account when developing a project plan.

- What size can a garage have, based on the available free space on a summer cottage? The width of the building, length and, of course, height are determined. If a garage is needed only for parking a car, then 3 m wide and 5.5 m long are enough. The height depends on the height of the car owner, because he will have to be in this room the most.

Sketch of a permanent garage built from bricks, blocks and other stone materials, with pitched roof, small window openings, ventilation system

Second stage: setting up a summer cottage

At this stage, they begin to transfer the diagrams sketched on a piece of paper to the real area. In the professional language of builders, this sounds like “terrain binding.” They determine the location of one of the corners of the future garage and drive in the first peg with a sledgehammer or a heavy hammer.

Next, using measuring instruments (tape tape, square), measure other angles and also drive in stakes. A thin nylon cord is pulled between the pegs, which can take up to 40 meters, depending on the size of the garage.

40-centimeter pieces of reinforcement with a diameter of 10-12 mm can be used as stakes. Usually it takes up to 10 pegs.

Third stage: excavation work

Active construction of a garage at the dacha begins with excavation work, during which a trench is dug for pouring a strip foundation. The width of the trench is usually 40 cm, but the depth depends on the degree of soil freezing in the area. An insufficiently deep foundation can cause cracks in the garage walls and other damage. In some regions, 60 cm is enough, while in others you will have to dig twice as deep.

To ensure that the bottom of the trench dug for the foundation is not loose, the soil is selected up to a layer with natural density (that is, the soil in this place should not be bulk). The walls of the trench are carefully processed with a shovel, ensuring their evenness and verticality.

Stage four: pouring the strip foundation

Of all types of foundations, it is worth choosing the rubble concrete option, since when pouring it, it is possible to reduce the cost of cement through the use of rubble stone. The work on installing a rubble concrete foundation is quite simple. Rubble stone is laid in rows in a dug trench, pouring cement mortar over each layer. The operations are repeated until the dug trench is filled to the brim.

When building a garage at the dacha, a rubble concrete foundation is poured. On the diagram: 1. Waterproofing. 2. A blind area that prevents water from entering the foundation. 3. Rubble stone filled with cement-sand mortar

It is important to note that the strength of the foundation directly depends on the quality of the cement. To prevent the garage building from shrinking and becoming covered with a web of cracks, it is necessary to purchase cement (Portland cement) of at least grade 400.

To mix the solution, take cement and sand in a ratio of 1: 2.5. In other words, to one part cement there should be two and a half parts sand. Water is added gradually, achieving mobility of the solution. They usually take the same amount of water as cement.

Stage five: construction of the base, installation of gates, construction of walls

Along the entire perimeter of the trench, formwork is installed level, using boards to fill the base concrete mortar. If construction site was not leveled initially, then the highest point is taken as the basis for measuring the height of the base. Add 10 cm to the base and draw the horizon. Two layers of waterproofing are laid on the dried surface of the base, for which a roll of roofing material is used. Horizontal waterproofing protects walls from penetration of capillary moisture coming from the ground.

Before starting the construction of walls, it is necessary to install metal Garage Doors, which will be fixed in the masonry. The strength of the connection between the gate frame and the wall is ensured by embedded parts welded to it in the amount of four pieces on each side. Round rods are used as embedded parts, the diameter of which should be at least 10-12 mm. When doing masonry, metal rods are embedded in the seams.

By the way, do not forget to paint the surface of the gate before starting installation, preferably in two layers. When installing, check with a level that their position is vertical; if necessary, place flat stones or iron plates under the corners. The exposed gates are supported by wooden braces.

Having completed the installation of the gate frame, they begin to lay out the walls of the garage using the chain laying method. In this case, the seams of the previous row are overlapped by the next row of cinder blocks or other stone materials chosen for the construction of the garage. In accordance with technology, masonry is always started from the corners. A cord is pulled between the exposed adjacent corners, along which the remaining blocks are placed in the row. Next, the corners are raised again, the cord is pulled again and the next row of blocks is laid out.

Using a building level when laying garage walls with your own hands allows you to ensure the evenness of all surfaces, both vertically and horizontally

Using a plumb line, periodically check the verticality of the walls. Close attention is paid to the verticality of the corners. The horizontal position of the laid rows is verified with a building level.

The garage floor also serves as its roof, so the end walls have different heights, thereby ensuring the necessary roof slope necessary for rainwater drainage. The upper part of the side walls is also sloping, with a height difference of five cm for every meter. The height of the front wall into which the garage door is built is usually 2.5 meters, and the back (solid) wall is 2 meters. If it is necessary to make the walls higher, then the masonry needs reinforcement, which is provided metal mesh, laid on every fifth row.

The cement-sand mortar used for laying garage walls is mixed in the following ratio:

- bucket of Portland cement grade 400;

- four and a half buckets of sand.

Water is added until the solution reaches the consistency of thick sour cream. Ordinary clay or lime paste will give plasticity to the cement-sand mixture. The finished walls are rubbed with cement mortar or plastered, and then whitewashed with lime.

To lay blocks at height, use scaffolding that must support a worker, several blocks and a container with mortar

Stage six: flooring and roof

The ceiling is made of steel I-beams, the height of which can be 100 - 120 mm. Such beams can easily cover a garage whose width does not exceed 6 meters. Add 20 cm to the width of the garage and thereby obtain the length of the beam. IN long wall the beams are inserted 10 cm, while the cinder blocks in the place of supports are replaced with blocks made of monolithic concrete. The beam laying step is 80 cm.

Then the ceiling is “sewn up” with 40 mm boards along the lower flanges of the beams. Roofing felt is spread on top of them, on which slag, expanded clay is poured or laid mineral wool slabs. Next, a 35 mm screed is made from cement mortar, the surface of which must be carefully leveled.

After the screed has completely dried, it is coated with a primer and coated with waterproof roofing material(for example, bicrost, rubemast, etc.), glued using mastic or by melting.

Seventh stage: installation of the floor and blind area

The garage floor must be concrete to support the weight of the car. A layer of fine crushed stone or sand is poured onto the leveled earthen base, compacted well and filled with a 10-centimeter concrete screed. Concrete is prepared from cement, sand and small crushed stone (1:2:3). With the help of exposed beacons, they monitor the floor surface, preventing the appearance of bumps and depressions.

Outside the garage, a blind area is built around the perimeter, the width of which is half a meter. Also, the earthen base is covered with crushed stone, on top of which concrete 5 cm thick is poured. The blind area is built at a slight slope, which facilitates the rapid drainage of rainwater from the walls of the car garage.

The interior decoration of the garage depends on the preferences of the car owner and the availability of additional purposes for using the room. Lighting and, if possible, heating must be provided.

Videos with a step-by-step example of construction

This is how you can, without haste, build a garage at your dacha with your own hands. By carrying out the work according to the plan and moving from stage to stage, you will be able to get a good, reliable place to park your car.