Everything new is not too forgotten old. This statement also applies to the so-called construction technology of Canadian houses. In fact, the method, which attracted the attention of domestic developers only in the current century, was used earlier in the territory of our state, and even more so in Canada, whose name the whole process structures.

Origin of the Canadian method

However, a technological process similar to the Canadian method was used in other countries - Finland, Japan and some other territories, where houses were built in the same way with minor modifications.

However, a technological process similar to the Canadian method was used in other countries - Finland, Japan and some other territories, where houses were built in the same way with minor modifications.

The main reason for creating such structures at one time was the issue of heat conservation. The latitudes of the northern states dictated the need to provide higher heat capacity, which became an alternative to heating technologies. Whatever type of energy is used to heat a house, you still have to incur significant costs during heating season. The motivating factor in the promotion of this technology was the appearance on the market of new technologically advanced materials with the ability to withstand low temperatures and keep the house warm.

And finally one more important point played a role in the development of this technology is the type of material used. In all regions where there is a need for such structures, there is a sufficient amount of wood, which is used as the main material for the frame and other elements of the building.

Advantages and differences of Canadian construction technology

Insulation materials began to appear several decades ago. Around the same time, the first structures began to appear using technology, later called Canadian. Its main advantage is that in such buildings, without additional equipment, it is possible to maintain a stable temperature, quite suitable for permanent residence. Of course, this does not eliminate the need for installation heating system, but its operation is much cheaper compared to houses made from conventional materials and built using classical technologies.

Insulation materials began to appear several decades ago. Around the same time, the first structures began to appear using technology, later called Canadian. Its main advantage is that in such buildings, without additional equipment, it is possible to maintain a stable temperature, quite suitable for permanent residence. Of course, this does not eliminate the need for installation heating system, but its operation is much cheaper compared to houses made from conventional materials and built using classical technologies.

And here another advantage of the Canadian structure becomes noticeable - cost. Such houses do not require a powerful boiler and large number thermal energy storage devices. This means that equipping a house with a heating system is initially beneficial to its owner, who avoids the cost of purchasing expensive heating elements.

At the same time, according to Canadian technology They also have the following advantages:

At the same time, according to Canadian technology They also have the following advantages:

- Speed of construction

- Low labor costs

- No seasonality

- Possibility to build house structures on almost all types of soil

- No need to involve professional construction equipment and special equipment

- Availability and ease of finishing work

- High design indicators, manifested in the ability to veil communication systems under the frame skin

- The prospect of constructing house configurations of varying complexity

When highlighting differences from other construction methods, you need to focus on the types of materials - they all have the ability to retain heat. Difference from brick houses and buildings made of foam blocks are considered to have a high rate of construction work. This is possible thanks to the use of easy-to-install panels and a small number of frame elements. This also includes such a feature as the area of the simultaneously assembled area - thanks to the size of the panels, it is possible to construct a significant size of the house structure in a short period of time.

Materials used for the construction of Canadian buildings

The main materials are the elements of the house frame:

The main materials are the elements of the house frame:

Next, to successfully complete the construction of a frame house, you need to have a board for it. In some cases, concrete is used, on top of which laminate or parquet is laid. In addition, construction work will require roofing materials And facing products- wallpaper, tiles, drywall and so on.

Construction of house panels using Canadian technology

The principle of creating panels for a frame house using Canadian technology is simple and affordable - you only need wood and insulating material. As the last component, all known modern roll-type insulators and material in the form of insulating boards can be used. These could be:

The principle of creating panels for a frame house using Canadian technology is simple and affordable - you only need wood and insulating material. As the last component, all known modern roll-type insulators and material in the form of insulating boards can be used. These could be:

- Foam plastic

- Penoizol

- Mineral wool

- Expanded polystyrene

In construction-oriented trade establishments you can also find analogues of the above materials, produced by different manufacturers and having different indicators of functionality.

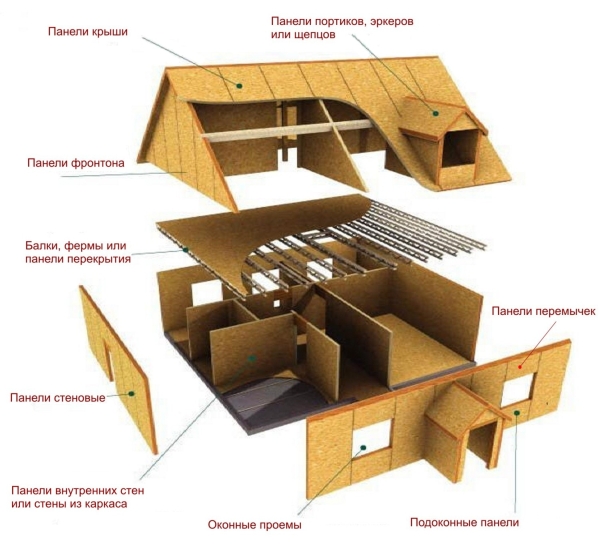

The panels have the format of a delicacy known in many countries – a sandwich. In honor of this similarity, they are called sandwich panels. Between two wooden bases Such a panel is covered with a layer of insulating material. The outer layers of the structure are tightly connected to each other. The simple design of the panels, however, has been developed in construction practice, resulting in the emergence of three modifications of this building element. The designs of the houses themselves began to differ according to the type of such panels:

Frame houses

A feature of these structures is the use of stronger timber with a cross section of 50 mm by 150 mm; panels assembled from such beams have a significant mass, but at the same time their thickness is also greater. Natural wood beams ensures the preservation of all the inherent qualities of this material.

Prefabricated panel structures

For these buildings, either a panel made of beams or a lighter structure made of . Such boards are a prototype of chipboards, but with improved technological parameters. Panels for such buildings are designed and built in factories, and their designs may include window and door openings. Such shields are heavy and are mounted using special lifting equipment.

For these buildings, either a panel made of beams or a lighter structure made of . Such boards are a prototype of chipboards, but with improved technological parameters. Panels for such buildings are designed and built in factories, and their designs may include window and door openings. Such shields are heavy and are mounted using special lifting equipment.

SIP panels

This technology is considered innovative. To implement it, OSB sheets are used, inside of which a layer of foam plastic is attached with an adhesive base of organic origin. The dimensions of such panels are usually classic - 2.50 meters by 1.22 meters.

If you are just thinking about building a house using this technology, we recommend that you familiarize yourself with the construction of a foundation for a Canadian house in. Almost every type of foundation is suitable for such a house.

Having studied the features of Canadian houses and become familiar with the properties and type of materials for their construction, two things become obvious. Firstly, the construction of such buildings is accessible even to those who do not have construction experience. And secondly, such houses are justified for reasons of budget savings, affordability of construction and operational process criteria.

Video on how to build a Canadian house

construction of a Canadian house

How to build frame houses using Canadian technology

Construction of houses using Canadian technology

Canadian house construction technology (reviews)

Doubts about what material to choose for building a house begin to plague its future owners even before purchasing the site. What should you give preference to so that the house turns out to be warm, durable, comfortable for living, and its construction proceeds quickly and does not ruin the owners? To make the right decision, you need to study not only information from manufacturers and developers, but also find out reviews from people living in such a house.

Opinions and reviews differ especially strongly about houses built using Canadian technology, that is, panel-frame houses. Many are so accustomed to durable and solid buildings that “frameworks” inspire outright mistrust. The statements of older people who lived in similar buildings in the middle of the last century are especially skeptical.

The first panel-frame houses, indeed, were not of very high quality, comfortable and durable. But time passes, construction technology changes, new ones appear finishing materials. Today, such houses have become much stronger, warmer, while remaining affordable.

What is Canadian technology?

Panel-frame dwellings came to us from Canada, hence their popular name - “Canadian houses”. Later, the technology was improved more than once. In each country (Germany, Finland, Sweden) various additions and improvements were made taking into account local climatic conditions. Half a century later, “Canadian houses” ended up in Russia. There is a certain advantage in this belated appearance: proven foreign technologies have come to us and have proven their right to exist.

A panel frame house can be compared to a multi-layer cake. On a frame made of timber, the manufactured industrially SIP panels. They are also called sandwich panels because of their multi-layer construction: insulation is sandwiched between two layers of particle board.

The top of such a house is sheathed with siding, clapboard or false beams. In addition, both inside and outside there is a special film that protects the insulation from negative impact environment and temperature changes.

Positive Feedback

Everyone is familiar with scenes from Hollywood films, where frame houses shatter into pieces from the blow of the main character. Actually this is not true. The owners claim that they very durable. Indeed, according to Canadian standards, they must be able to withstand not only a small tornado or earthquake, but also much more common troubles, such as a half-meter layer of snow on the roof or the ravages of time. The service life of the first houses built in Russia using Canadian technology has exceeded 20 years, but they still look new and delight their owners.

Panel frame house builds very quickly This is appreciated by those who are limited in time, for example, by the need to repay a loan to build a house. Its construction does not require a complex, labor-intensive and expensive strip foundation. The final weight of the structure is small compared to a similar structure made of brick, blocks or logs.

The “Canadian” house does not shrink - this is important for those who are in a hurry to move into it. You can begin interior decoration of the building immediately after construction is completed: the tiles in the bathroom will not burst, the plaster will not crack, and the wallpaper will not peel off.

Another advantage of a frame house is that it is relatively inexpensive construction technology. Such a house will cost less than building a brick cottage, and the level of comfort in it will not be lower. The price-quality balance can be considered ideal for most ordinary consumers.

Warm frame house. Experts claim that thanks to the use modern materials the thin walls of a panel-frame building are equivalent to meter-long walls made of brick or expanded clay-concrete blocks. At the same time, heating them requires much less resources. How true this is can be seen by reading the forum threads dedicated to heating frame houses. Some owners manage to heat the entire house with just two oil heaters!

Negative reviews

Unfortunately, houses built using Canadian technology also have disadvantages. At incorrect assembly construction, high heat losses through cracks are inevitable, although the house itself is quite warm. If the walls, floor, ceiling and roof are assembled without technological violations, it will definitely not be cold. On the other hand, when assembled correctly, the house is like a sealed thermos, and it needs ventilation, at least in the form supply valves and a common ventilation pipe.

As with building houses from other materials, materials must be selected carefully. Owners of frame houses, who decided to save money on this during construction, complain that over time the frame made of raw wood begins to leak, and cracks appear in the cracks. Another common nuisance is mold, which is almost impossible to remove from such a house, since the frame is covered on all sides with panels.

Raises some doubts strength of the house. Not the durability of the building, but rather the strength. Not everyone is pleased to realize that they are quite separated from the street. soft materials- siding, insulation, interior cladding. However, this is rather a psychological problem and a lack of a sense of security.

They talk about low sound insulation. Indeed, in the panel frame houses it is slightly lower than that of similar buildings made of denser materials. But this can be compensated for by additional layers of special noise-insulating material and a thicker layer of outer cladding.

Is it possible to call a panel-frame house optimal choice? For a young family with a small budget - yes! This is practically the only chance for independence from the clumsy central heating, noisy neighbors and other unpleasant circumstances.

The technology for creating composite materials and the panels themselves for building a house using Canadian technology make it possible to obtain high-quality housing at an affordable price, which has a lot of advantages. At the same time, a structure can be built extremely quickly, in a matter of weeks, after which the final finishing of the building is carried out immediately, since shrinkage amounts to hundredths of a percent. Thanks to the low mass of composite parts, this task can be solved quite successfully. However, like any technology, Canadian technology has disadvantages, as well as pitfalls that an inexperienced developer of residential building projects may encounter.

What is a SIP panel

The composite for building houses using Canadian technology is quite simple in an engineering sense. SIP panel consists of:

- finishing, which is oriented particle boards. Depending on the class of the SIP panel for houses and its purpose, cladding of different thicknesses and densities is used;

- insulation, modern parts for construction using Canadian technology use free-foam polystyrene foam. This is a very strong, light, durable raw material. Unfortunately, there are SIP panels on the market in a frankly cheap segment, where polystyrene foam is used.

Three layers of the composite (two cladding slabs and insulation) are connected to each other using a polymerizing special glue. It is applied at the factory, technology ensures full coverage surfaces.

After polymerization is completed, all parts of the SIP panels for building houses using Canadian technology are connected over the entire contact area. This guarantees high strength of every part of the building and reliability of connections. Empirical tests show that a standard SIP panel, used to build house walls using Canadian technology, can easily withstand the weight of an average SUV.

There are different classes of composites on the market. They differ in both insulation and cladding slabs. For example, CSP (cement particle boards) guarantee high resistance to moisture, CML (magnesite) have record strength indicators, zero reaction to water, and have a perfectly flat surface. The technology used for installation is the same for any class of composite.

A separate segment of SIP panels for construction using Canadian technology is intended for the construction of industrial buildings and structures functional purpose. The role of insulation in this material is specially treated mineral wool made of basalt fiber, and the cladding is galvanized, non-corrosion sheets of metal.

On external slabs profiling is done to increase strength indicators, and groove connecting locks are formed on the edges of the parts, which facilitates installation. It is possible to construct a building from a composite of this class in a matter of days.

Negative opinions about technology

You can find many negative reviews about SIP panels for building houses using Canadian technology, which mainly come from developers who work with classic materials. We will try to debunk most of the myths.

The main disadvantages of houses made of SIP panels are associated with emergency situations, primarily fires

This opinion is not true. If we take it as a guide wooden houses, buildings made from SIP panels have, even when using the cheapest composites, much greater resistance to the elements. Facing OSB resists direct exposure to flame for one and a half hours. Both the cladding and the insulation do not have the ability to support combustion in air of normal composition.

Implies a careful approach to the issue of security. Treat the wooden parts of the building with special impregnations, lay the wiring in a corrugated sleeve or install it in steel tubes, carefully develop projects engineering systems houses. The main requirement is to follow the basic rules for using heating devices. Issues of ensuring the fire safety of a development project also play an important role, since nearby wooden buildings most often cause trouble.

Wooden parts of SIP panels for houses of Canadian technology are destroyed by rodents

This factor is difficult to assess and predict. Rodents of all kinds breed anywhere. In concrete skyscrapers, damp basements, they destroy wiring, concrete structures, bricks. If you want to guarantee, or rather, reassure yourself that there are no terrible problems from the actions of mice and rats, you can protect wooden structures during the installation of a house using Canadian technology using steel mesh. But it’s better to use traps or preventive measures in the form of impregnations.

Harm to health

The opinion that SIP panels in houses of Canadian technology emit harmful substances is completely untrue. Expanded polystyrene is the most neutral material; bacteria and mold do not multiply in it; the walls of the microchambers in which air is clogged are very durable. The insulation has no micropores and does not conduct gases and steam. Cladding material for houses uses much less binder than chipboard and MDF for making furniture. And the connecting glue that is used in the composite is certified by a huge number of countries and is safe. Therefore, if you decide to build a house using Canadian technology, it’s a matter of allocating harmful substances shouldn't even be on the agenda.

Mandatory forced ventilation of a house made of SIP composite

A factor that, so to speak, takes place. However, it is incorrect to say that after installing a house using Canadian SIP technology, people are placed in a thermos. Rationally and thoughtfully designed projects always involve natural, so-called convection ventilation. But if you want to follow the path of technological progress, you can install modern convector heaters for Canadian homes. This small device, placed in the window opening area, controls humidity, temperature, supplies air from outside and is capable of preheating it.

As can be seen from the above, building a house from SIP panels has disadvantages, but they cannot be called significant or unexpected. In fact, if you implement a residential building project from any materials, it cannot be characterized only by positive features.

Mistakes of novice builders

If you decide to build a house from SIP panels using Canadian technology, you shouldn’t get carried away and flaunt it. The composite has great strength. This blinds the eyes of novice builders, and they begin to save money, install large elements without using measures to strengthen the structure of houses, and make mistakes in design. The most typical are:

- desire to save time and money. Construction involves the installation of large elements, this allows you not to cut parts, work at great speed, using less timber;

- simplification of power structures of houses. Installation of an interfloor floor made of solid slabs, a floor covering in the corridor made of a long section of SIP panels - all these elements will eventually become loose and begin to creak.

The list of beginner mistakes can go on for a long time. Therefore, if you decide to build a house from SIP panels using Canadian technology, it is better to use a project created by a specialist or order its development from an architectural company.

Panel-frame houses using Canadian technology

Houses built using Canadian technology are distinguished by ease of installation, efficiency and durability. They are not afraid high humidity and earthquakes. Buildings made from SIP panels have become more and more common in suburban areas. What is the secret of their success?

“Canadian” houses are buildings built using SIP technology (Structural Insulated Panel). They are assembled from pre-fabricated panels at the factory. Sometimes such structures are mistakenly called frame structures, although they are more typical “panels”. However, sometimes the design of such a house actually includes a frame base. But today we will talk about classic panel houses, manufactured using Canadian technology.

Advantages of houses built using Canadian technology

The main advantage of SIP technology is that it has been actively developed in countries North America and Europe, and in the process of designing houses, every detail is taken into account. "Canadian" houses have withstood hurricane winds and other bad weather and have repeatedly proven their effectiveness due to numerous advantages.

Unique thermal protection and thermal insulation

Although the walls of Canadian houses do not look massive and durable, they are pressed from “warm” materials, thanks to which they have achieved impressive thermal insulation. SIP panels do not require additional insulation, unlike brick or frame structures. Innovative walls also have a positive effect on the usable area of the house - it increases only due to the fact that the panels take up less space compared to walls in conventional houses.

Light weight of slabs

Canadian panels are distinguished by very low weight. Most of their mass is occupied by polystyrene foam - a lightweight and durable material. The role of the frame is performed by a block, and inside and outside this “sandwich” is covered with OSB boards. And if brick wall with an area of 1 sq.m. will weigh more than a ton, then the weight of 1 sq.m. of a wall made using SIP technology will barely exceed 20 kg. Lightweight panels reduce foundation costs: for such houses, a strip or column foundation will usually be sufficient. These houses can also be built on difficult soil - with close proximity groundwater etc. In addition, you can build floors from SIP panels above existing floors.

Good sound insulation

Maybe, private house does not need soundproofing as much as city apartment, however, home owners also periodically think about unnecessary sounds. And again, SIP panels are in the lead. They significantly reduce noise levels and dampen indoor sound.

The degree of sound absorption of a SIP panel can be compared with brick wall. They absorb shock waves and vibrations less well (for example, those occurring when walking), but if you lay carpet on the floors, this will significantly reduce the background noise inside the room.

Increased strength

Canadian technology was developed taking into account the seismic activity of certain regions. Therefore, houses built using this technology can withstand longitudinal load 18-20 t and transverse 3-3.5 t. This is excellent result for such a light and thin material.

Minimum construction time

A house using Canadian technology can be erected within a few months. And for this you will not need to involve any special equipment or hire one-of-a-kind specialists. “Wet” solutions are not needed, so work can be carried out in any weather. Interior work You can start finishing work almost immediately after the construction of the “box” - after all, a “Canadian” house does not shrink. The material also retains its shape, so the walls and floor are always level.

More light!

It is always very light in a house built using Canadian technology. In this case, windows can be installed smaller than, for example, in a brick building.

Disadvantages of houses built using Canadian technology

There are only three disadvantages to a “Canadian” house. At least, this is the opinion of some builders, who are still wary of the new “unknown material” from which houses are made. However, upon detailed study, it turns out that these shortcomings are indirect and can be completely neglected.

First disadvantage: the flammability of Canadian houses

Indeed, according to the degree fire danger panel houses of SIP panels are classified as class K3. It's similar wooden house. At the same time, it is often forgotten that the polystyrene foam “filling” actively prevents the spread of fire across the surface of the building. Also, the panels do not emit toxic substances such as carbon monoxide, released during the burning of wood. An additional layer of plaster or drywall can reduce fire hazards.

Second disadvantage: rodents love them

This is not always fair. Not all rodents will be able to chew through the layer of OSB coating and boards, as well as cope with the solid substances with which the slab is impregnated.

Canadian style homes are becoming increasingly popular. This is due to many factors: economy, efficiency, lack of shrinkage and no need to use heavy special equipment. And if we take into account that Canadian houses are very popular in harsh latitudes due to their high ability to retain heat, then the desire of developers to learn as much as possible about such technology becomes understandable.

Panel arrangement

The principle of creating panel elements is quite simple: wood boards with thermal insulation material laid inside are held together with an adhesive composition. The main thing is to tightly glue all the elements, having previously selected required thickness heat insulator. The latter can be mineral wool, polystyrene foam insulation, penoizol and others. The design of a simple type is widely used in construction, and modifications of all are allowed building elements, Canadian frame houses began to be distinguished by the type of panels:

- Frame technology involves the use of durable timber with cross-sectional dimensions of 50*150. The panels are heavy, but also very thick. Natural wood, of course, is more expensive, but this indicator is compensated by maintaining the highest practical and aesthetic qualities of the products.

- Prefabricated panel Canadian technology construction - these are elements where it is permissible to use timber panels or lightweight structures made from OSB sheets. These structures are the prototype of chipboard. The boards are manufactured in a factory manner and can be equipped with doorways, window frames and other elements, if they are included in the project. The elements are heavy, so they will have to be installed using special equipment.

- SIP panels are the most popular innovative option today. Implemented using block elements, which are two OSB sheets with a sheet attached between them thermal insulation material. Standard sizes 2.5*1.22 m, weight from 56 kg. Durable and practical slabs have high thermal insulation characteristics, which allows you to save on heating costs, and large format elements make prefabricated houses using Canadian technology even more attractive to developers.

Advantages of houses

When considering frame houses using Canadian technology, you should take into account the following advantages:

- Inexpensive cost of building materials and fasteners.

- Efficiency and all-season installation of buildings. Arranging a house from sip panels from the foundation to the roof can take 3-8 weeks, after which all communications will need to be laid, interior decoration and arrange the furniture.

- No use of heavy equipment and minimum earthworks.

- Wall panels have a high energy saving rate, which means you don’t have to spend money on additional insulation and heating of the building.

- Excellent sound insulation.

- Minimum requirements for the foundation: sip panels have a lightweight mass, so it is possible to install strip and pile foundations.

- Possibility of laying communications in a hidden way.

So what is a Canadian home? This is a building characterized by practicality, warmth, quick construction and affordable cost. Home improvement is done with minimal effort. When ordering panels, the material is delivered numbered, and all work is reduced to assembling the elements using self-tapping screws. Having minimal construction skills allows you to complete all the work yourself, having previously purchased polyurethane foam for filling seams and a large number of screws (they will always come in handy).

Limitations for frame frames using Canadian technology

Not only the nuances of construction work are mandatory, but also compliance with the rules established by the design documentation. In particular, these are climatic, geological and other regulations adopted in each specific region.

- The height of the house does not exceed 3 floors;

- The distance between internal walls located perpendicular to the load-bearing ones should not be more than 12 meters;

- The total area of window and door openings cannot exceed more than 30% of total area walls;

- The load on the floors between floors is permissible up to 2.4 kPa;

- The calculation takes into account wind and snow loads, the parameters of which are considered in the SNiP of each specific region.

FYI. Thus, the Canadian technology for constructing frame private houses must fully comply with the above rules and before starting construction it is a good idea to clarify the established regulations and tolerances.

The material requirements are as follows:

- A frame house can be built from lumber with the required moisture content of no more than 15%. The use of coniferous wood is allowed. In this case, all elements must be subjected to pre-treatment antiseptics, antiprens and be carefully protected during transportation.

- Additional materials used in sip panels, as well as insulation, finishing, slab elements, cladding, roofing products, sealants must meet the requirements and have hygienic and fire safety quality certificates.

Features of frame construction

It all starts with the foundation. Canadian construction technology allows for the construction of lightweight foundations. The structure of the building is quite light, but extremely strong due to numerous stiffening ribs, so it is possible to erect buildings on any type of soil. The foundation can be a pile foundation, slab foundation, strip foundation, or columnar foundation with a grillage. Most often, developers make do with pile-screw foundations or use an insulated Swedish plate.

The main elements used for the construction of frame houses using Canadian technology are wood and slab fragments with which the walls are sheathed. Insulation is laid between the panel sheets and the frame stand. And then everything is simple:

- Installation of the first floor floor platform under a wooden frame skeleton;

- Assembly of walls in a horizontal position;

- Lifting wall sip panels and installation on the lower strapping beam;

- Alignment of the structure;

- Installation of the top trim;

- Arrangement of interfloor ceilings or roofing.

The process of constructing a building is never long; in addition, the construction technology is unique - houses do not shrink, so there is no need to wait an additional period, and you can immediately begin interior finishing work.

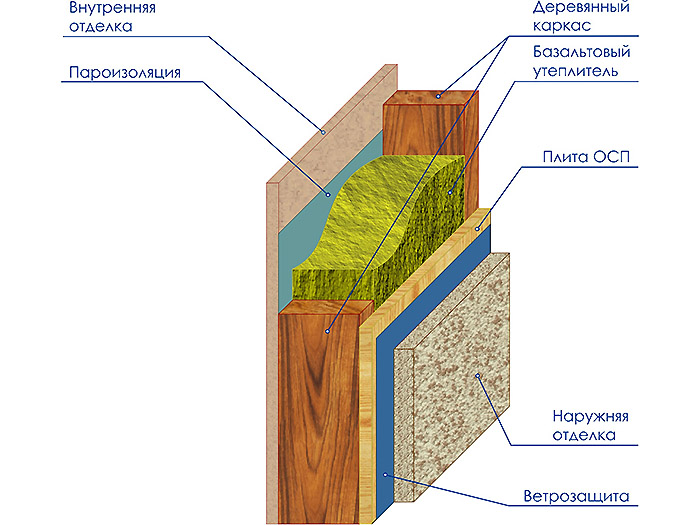

Standard “pie” of a wall panel, insulation options

Small price square meter and high thermal conductivity of houses from Canada are due to the use quality materials and insulation. As for the “pie” of the wall, it consists of the following elements:

- Outer facing layer;

- OSB board;

- Hydro- and wind insulation membrane;

- Insulation;

- Vapor barrier membrane;

- OSB board;

- Interior finishing.

The insulation insulated between the slabs and membranes plays a huge role; not only the preservation of comfort depends on it temperature regime, but also soundproofing. In classic sip panels it is used stone wool or ecowool.

Stone wool based on basalt fiber has a reduced thermal conductivity, is a breathable material and is affordable. There is a drawback: the slightest moisture will lead to a complete loss of the quality characteristics of the material.

Ecowool is non-toxic, retains heat well and allows steam to pass through. Lack of rotting, resistance to open fire, low cost are also advantages of the material. Ecowool is applied either by spraying or simply poured into the cavity.

Roof

The most common materials for roofing are: ceramic or polymer-sand tiles. But at the request of the customer, it can be asbestos-cement sheet, ondulin, slate. The low weight of sip panels with high strength allows the use of any roof, as long as the slope of the roof slope corresponds to the permissible angle of inclination of the roof made of the selected material.

Facade cladding

There are also no special restrictions here. Good sound insulation and the evenness of the surface, which they possess, reduces the finishing requirements. However, regardless of the choice of materials, it is necessary to comply with the established protection requirements interior spaces home from exposure to external atmospheric phenomena.

Having completed the construction of a Canadian house, it is worth once again checking the presence of drainage holes and drainage systems - these are reasonable precautions that prevent the accumulation of moisture in the space between the frame and the cladding. If it is necessary to reduce the noise threshold, you can add a soundproofing layer and create an air gap.

Advice! Careful sealing of the joints between the sheathing elements and the places where they connect with window and door openings minimizes the risk of precipitation getting into the internal space between the frame and the finish.

Frame construction is a simple and inexpensive process compared to many other options for constructing low-rise housing. At the same time, the construction of sip using Canadian technology must not only comply with the standards adopted in the Russian Federation, but also be carried out taking into account all the nuances. Otherwise, the customer risks being left with a cold house, which will constantly need heating and improvements. That is why you should give preference to trusted developers. As the professionals say: “a cheap construction crew is what you pay for their training.” Perhaps, somewhere, some errors and shortcomings are acceptable, which are then covered up by finishing, but not in the construction of buildings using Canadian technology - the slightest violation will manifest itself in a decrease in the performance of the building.

Well, to visually imagine what a mansion from Canada is and choose your project, see photos of Canadian houses. These are aesthetic and diverse buildings, characterized by lightness of form and very high living comfort, otherwise the technology would not have been popular in such a practical country for at least a couple of centuries.