It's no secret that for comfortable stay In a private house, heating is necessary - sometimes it is impossible to live without heat even in the summer. And if for a small one-room house a small “potbelly stove” is quite enough, then for two-story house something more serious is needed. And the temperature in all rooms needs to be the same. It’s no good if a person languishes from the heat in one room, and freezes in the next room. Today we will try to understand which heating scheme for a 2-story private house is better, whether it is possible to design and install it yourself and what nuances each of them has.

Designing and installing heating systems in two-story private houses is a rather complex process, but quite feasible. And no matter which of the existing schemes is used, installation will not require any special skills. Enough basic rules and careful and strict adherence to instructions. Today we will try to provide this information to our dear reader in as much detail as possible.

Heating in private houses can differ not only in the energy component, but also in the distribution systems - they can be either single-pipe or double-pipe. What advantages one scheme has over another remains to be seen. And how accurate home handyman will understand the difference, the quality of subsequent design and installation depends, as well as the comfortable temperature in all rooms of the building. In the meantime, we can say one thing - having in our hands detailed diagrams water heating in a private house, it is quite possible to install it yourself. But first, let’s figure out what it can be, based on the energy component.

Energy sources for heating a house, their features, as well as positive and negative qualities

Heat sources in residential buildings can serve:

- Electricity– these can be not only various heaters, but also boilers connected to a hydraulic heating system;

- Natural or liquefied gas– again boilers or various heaters (for example, infrared);

- Alternative systems– geothermal heating;

- Using solid fuel– in other words, stove heating.

Previously, houses were heated mainly using stove heating, but now more and more people are switching to electricity or gas. The fact is that progress does not stand still and new types have become much cheaper than solid fuels such as coal or firewood. There is one more advantage of all other types of heating over stove heating - no time or effort is required to transport fuel, prepare it and remove waste combustion products.

So, let’s figure out what this or that type of energy used for heating is.

Heating a private house with electricity - the advantages and disadvantages of such a solution

Nowadays, when many new types of heaters have appeared, such heating has become very economical. But installation in each room of a two-story house infrared heaters or convectors - it’s quite expensive. In addition, it is not a fact that the electrical wiring was installed taking into account such loads. This means that the only option left is to install an electric boiler with. Some homeowners argue that it is cheaper to buy a tankless heater that does not require a storage tank. However, this is a misconception. Indeed, in this case, the boiler will work constantly, 24 hours a day, and with such operation, all savings from the purchase will be negated in the first months of use.

But we won’t talk about it in too much detail today; there is a separate topic for that. Now it is important to understand that the use electric heating in a private home, with proper installation and selection of equipment, it can become a fairly convenient and economical way of heating.

Important information! If you plan to purchase an electric boiler, you need to make sure that the wiring in the house is designed for the load that it will consume. Ideal option There will be installation of a separate line specifically to the boiler with the installation of an automatic circuit breaker and a residual current device.

Related article:

How to significantly reduce costs? We will consider the most economical method in more detail in an article on our portal, comparing some types of heating systems.

Heating a private house with gas and what difficulties are associated with it

A similar system, if it works from natural gas, is also very economical. And yet its installation is quite complicated and impossible to do with your own hands. All work must be carried out service organization, having all the licenses and permits for this. And this, as you might guess, is quite a large cost to pay for their labor. Even the internal installation of a boiler yourself is strictly prohibited, unlike an electric one.

Periodic inspections required during operation, which are also performed only by a licensed company, also become costly. On condition if private house heated gas cylinders, costs increase several times. But even despite this, such systems remain in demand due to the fact that they are still more economical than purchasing and using solid fuel.

Heating a private house gas boiler, in the absence of periodic audits and checks, becomes very dangerous. Very small leak liquid fuel indoors may cause an explosion. That is why homeowners try not to skimp on the services of professionals.

Related article:

As part of this review, we will try to sort it out. How to choose best option and set priorities for ordinary users, what models exist, and how to properly carry out installation on your own.

Heating a private home with solid fuel is gradually becoming a thing of the past.

Or coal is really gradually disappearing from our lives. Of course, it will never completely disappear, even if it remains in the baths. After all, what would a Russian bathhouse be without the birch smell and smoke. Well, in houses, of course, such heating today is extremely irrational. In addition to the expenditure of effort and time, there is also a rather noticeable expense in financially– Firewood is very expensive these days.

Of course, the stoves have not left the houses. Now they are being modernized everywhere for gas. But as heating in a private house without gas and electricity (which is extremely rare), this option is quite good. After all, if compared with imported liquefied gas, there are savings due to the absence of the need to install additional equipment and maintain it. It turns out that, although heating private houses without gas and electricity cannot be called economical, it also has a right to exist.

The use of alternative heating in private homes and what it is

This type is quite rare for Russia, although in America and Europe almost all private homes are heated with it. The essence of geothermal heating of a private home is to use the heat from the lower layers of the earth. After all, still from the course schooling everyone knows that the deeper, the warmer the soil. The principle of this method is based on this. The main work here is performed by a heat pump, which concentrates high temperatures, subsequently supplying them to a private house.

This kind of heating has a lot of positive qualities. For example:

- Absolute fire safety - there is no need for gas or any other fuel;

- Economy - the only cost item is electricity, which requires a negligible amount to operate the heat pump;

- Silence;

- Operation in two modes - heating in winter and cooling in hot weather;

- Environmental friendliness - no harmful emissions into the atmosphere;

- Compactness - the owner does not need to equip a separate room in the house for a boiler room or boiler room.

Of course, most often such systems are laid out at the construction stage. But Russia is not yet accustomed to such heating. Let's hope things change. After all, this is indeed a very profitable option for heating in winter and cooling in summer - after all, there is no need to purchase and install air conditioners and other similar equipment.

Differences between open and closed heating systems: advantages and disadvantages of each of them

Those who have encountered the installation of heating systems know that they can be either closed or open. If not, then now we will try to explain what they are and how they differ.

Schemes of closed heating systems with forced water circulation imply sealed lines. This prevents the pipes located at a higher level from airing. When the water heats up, the valve is activated and the excess flows into the expansion tank. When cooling, the reverse process occurs. A closed-type heating circuit with a circulation pump is implemented in all apartment buildings. Its main advantage is the absence of evaporation and the possibility of using thinner pipes. In such a system, the use of any type of boiler is allowed, regardless of the fuel on which they operate.

The layout of the open-type heating system is fundamentally different from the previous one. The expansion tank, which is located above the level of the boiler and all pipes, is connected to the system directly, without any valves, which means that when the water level decreases, air may enter the highest points, which will lead to the cessation of circulation (in this case it is natural).

The size of the pipes when using an open heating system in a private house is much larger. For this reason, the costs of its installation increase. It is also inconvenient that it is necessary to use as few shaped elements as possible, such as knees. At large quantities When turning, circulation slows down. Cannot be used as a heater electric boilers. After all, the movement of water is quite slow, and therefore there is a danger of it boiling and failure of the heating elements.

And of course, one cannot help but dwell separately on the types of circulation.

Forced or natural - which is better to give preference to and what other types are there?

Natural circulation is the independent circulation of water in the system, without the use of a pump or pump. Used when installing an open heating system. The fact is that when installing a recirculation pump in this case, the water will take too long to warm up due to the large diameter of the pipes.

Heating diagram for a two-story house with natural circulation quite difficult to implement. This applies not only to the size and number of pipes. The main task is to create the necessary uniform slope of the highway along its entire length. And it’s not easy to do this on such a scale.

A heating scheme with forced circulation of a two-story house is free of such problems, and therefore it is much easier to install - water moves through the pipes using a pump. This means that a uniform slope is no longer necessary.

Important! If the circulation is forced, then you should not think that you can install radiators and mount pipes at random. In any case, accuracy is important. Here, all pipes should be located horizontally and vertically, and radiators should be strictly vertical.

It becomes clear that when choosing between a forced and natural (gravity) heating system for a two-story house, you need to make a decision based on your capabilities and desires. But still, a closed one, according to experts, is more reliable, easier to implement and requires lower financial costs.

Features of various wiring, their pros and cons, as well as the nuances of installing various circuits

Before installation, you need to complete the most important part of the work - draw up a wiring diagram for the heating system in a private house. After all, no matter how simple it may seem, without detailed project can't get by. Especially if you plan to heat a two-story house with many rooms. In addition, he carries within himself another useful function(if really detailed). It is according to the heating project for two-story houses (as, in fact, any others) that one can calculate the number required material, shaped elements and radiators. And based on this data, it will be possible to determine the upcoming costs. But this is a rather important point.

Many people believe that it is very difficult to do such work as installing heating in a private house on their own and that such work can only be done by professionals. However, this is not true. And to prove this, we will now present to the attention of our dear reader several various schemes, which can be used to perform a similar installation. And after that, everyone will decide for themselves which one is closer to them and which one is easier to do on their own. Although, looking ahead, we would like to say that, having understood the very essence of these schemes, it becomes clear that any of them is quite simple.

Single-pipe systems: how to install them

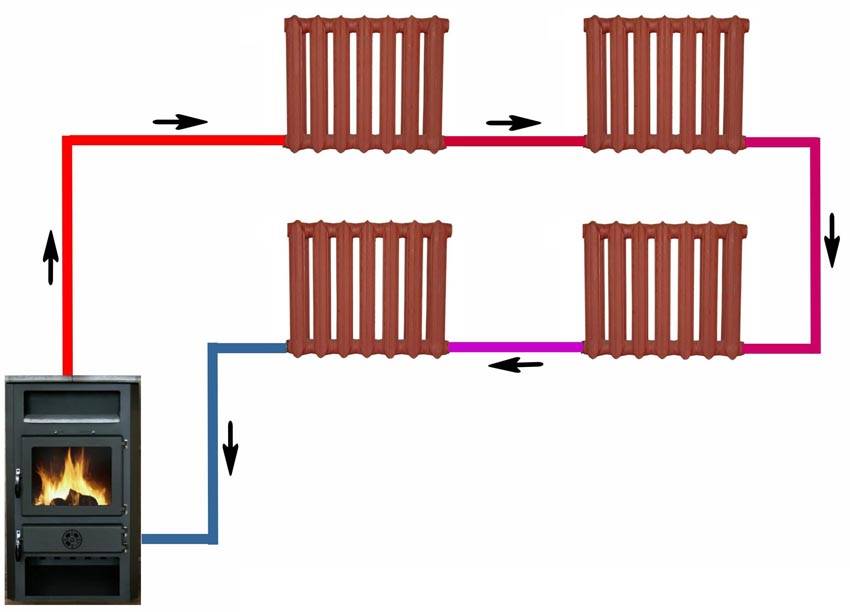

This is the simplest, and therefore the most common heating installation system. Its name already speaks for itself. For convenience, we will try to explain its essence in simple and accessible language. Let's take a room with 5 radiators installed around the perimeter. Then the hot water, leaving the boiler, enters the first radiator, passes through it and goes to the second, and so on in a circle. The output from the last battery is connected to the boiler return. It turns out that one pipe runs around the perimeter. It does not matter how the radiators themselves are mounted to it - whether it will be a parallel connection or a serial one. It also doesn’t matter whether the diagram of a single-pipe heating system will be with bottom wiring or with top wiring (we’ll talk about this a little later).

It is this type of connection that is most often used in houses with a small number of rooms - it allows you to significantly save on the purchase of material. A single-pipe heating system for a private house is quite convenient and unpretentious, but it has one drawback. As the number of radiators increases, the temperature of the last one in the chain will be noticeably lower than the first. This is explained by the fact that the water has time to cool down while it passes through all the rooms. This means that the diagram of a single-pipe heating system in two-story house with a large area and many rooms will not work. This means that other options should be considered.

Two-pipe systems and their advantages in houses with large areas

The design of a two-pipe heating system in a two-story house is also not complicated, but it has its own fundamental differences from the previous version. Taking the same room with 5 radiators around the perimeter, you can build the following “project”. There are two pipes running from the boiler along all the radiators - supply and return. At the last radiator they are connected to form a closed circuit. The connection is made as follows. Hot water from the boiler enters each of the radiators, and from it it returns to the return line (back to the heater). Thus, we get a system in which each heating device works directly with the boiler. It is in this case that there will be virtually no temperature difference between the radiators, which is what is required for comfortable living.

Installing double-circuit heating in a private house with your own hands is not difficult, but it requires care. In addition, material costs increase. But sometimes there is simply no other option. In addition, with such a device, even if in winter you open a window in one of the rooms, cooling it down to the outside temperature, even this will not affect the remaining radiators too much - they will be almost as hot. At the same time, a two-pipe heating system with overhead wiring can be made with both forced circulation and natural circulation. One of the varieties of such a system is the “Tichelman loop”. We will talk about it now.

Tichelman scheme - what it is and why it is better than a conventional two-pipe system

If you look at Tichelman’s diagram for two-story houses, you can see one interesting detail. Innings hot water The same is done to the first radiator, but the return flow comes from the last one, although both pipes run along the perimeter. Thus, a kind of loop is obtained, which, as it were, combines two connections - one-pipe and two-pipe.

The advantage of installing a Tichelman loop on two floors is that even the slightest difference in the temperatures of the radiators disappears, regardless of which room or room they are located in. Of course, such a system will cost a little more, and therefore it is worth using it only in cases of really large areas and the number of radiators.

Tichelman’s scheme for a two-story house is quite interesting both in terms of design and installation, but it also has its own difficulties. It's much easier to get confused with her. It would be advisable to first stretch one pipe, marking each of its branches to the radiator, and only then take on the second one. Otherwise, there is a chance of mixing up the supply and return.

Leningradka scheme: are there any differences between it and a conventional single-pipe system?

If we turn to a conventional single-pipe system, then Leningradka can be called one of its varieties, and now we will explain why. In fact, taking the same room as an example, with a single-pipe system you can connect radiators in series, which makes it impossible to adjust the temperature of each of them separately. By connecting the heating of a private house with your own hands according to the Leningradka scheme, you can get this opportunity.

Installation is carried out as follows. The pipe from the boiler also runs along the perimeter of the room, but is not interrupted anywhere. Through such shaped parts as tees, both the supply to the battery and the return from it are connected to it. In this case, by installing the regulator on the radiator, you can freely adjust the temperature, setting it to comfortable - this will be the Leningrad heating system. The scheme for a two-story house is quite simple, which means it can be easily done with your own hands, even by a home craftsman who does not have such experience.

Of course, two-pipe circuits are much more reliable and distribute heat better, but if the area of the house is small, then such a circuit will come in handy. It is also possible to perform top wiring. Of course, this is a little more complicated, but then there is the option of installing heating with natural circulation.

It is precisely due to its simplicity that such a scheme has received quite widespread among homeowners. If the building area is large enough, then the Leningradka system is unacceptable for heating a two-story house.

Collector heating system - what is its advantage

The use of a collector heating circuit in a two-story house is a fairly rational solution that is suitable for both one-pipe and two-pipe systems. Let's try to explain what it is.

It is clear that in a two-story house there is more than one room - there are several of them in one. This means the question arises of distributing the hot water supply from the boiler to different radiators. To avoid installing many loops, you can do the following. At the outlet of the boiler, a collector is installed, from which as many pipes depart as there are rooms on the floor. For the second, it is better to install a separate one, through a tee. Shut-off valves are also installed on each supply outlet. As a result, we get each room connected separately, the heating of which can be turned off if necessary. The same steps apply to the return line, but without shut-off valves.

It is this system that will allow you to get by with only one pump. In the case of connection through tees, you will have to install a second one, because one simply cannot cope with two floors. And for a more complete understanding of this topic, we suggest watching a short video about collector heating in two-story houses.

Many people call this home heating radiant, which is also correct. If we consider a conventional two-circuit system, then it is simply impossible to do without the use of such a scheme - after all, a person will not install a two-pipe scheme for 2-3 rooms.

As for installation, the radiant heating system is also at its best - with its use, the implementation of such work is greatly facilitated. In other words - negative qualities We couldn’t find it in it, although we tried very hard. If any of our respected readers succeeds, we kindly ask you to write about it in the discussions, we will be very grateful.

Now regarding the use of radiant heating systems in private houses with a single-pipe scheme. And here it does not fail, comparing almost perfectly the temperature readings of the first and last radiator in the chain, even without the use of a Tichelman loop. This means that the collector system can be considered a real find.

Thermal engineering calculation of a heating system: why it is needed and how to do it

First, let's try to understand why it is needed and what we can ultimately learn.

| Options | Description |

|---|---|

| Boiler power | Indeed, having carried out complete calculations, we will determine this parameter with accuracy. This is necessary in order not to purchase a boiler of less power than necessary (there will not be enough heat to heat all the rooms) or more (why overpay for unnecessary excess consumption of fuel or electricity) |

| Radiators power | This is necessary to determine whether the heat they generate is enough for the room in which they are located and whether they will have to be kept covered, which again will hit your pocket when purchasing |

| Monthly heating costs | Budget planning is a fairly important component. Knowing how much you will need to spend per month, this process will be much easier. |

| How to reduce heat loss | This is also very important. After all, in the absence of heat leaks, savings on heating the house increase. We will definitely talk about this today |

| Will moisture accumulate? | This factor is important not only from the point of view of dampness as a component of heat loss, but also as a factor determining the service life of the house itself. |

Of course, it is better to hire professional designers for this purpose, but in this case the payment for their services will be quite an impressive amount. If this is unacceptable, it is better to calculate the heating of a private house yourself. But you need to be prepared for the fact that this will be quite difficult. Let's look at the main things you need to know for this.

Calculating the power of a heating boiler based on the area of the house is the simplest step

According to generally accepted rules, 1 kW of power is required for every 10 m2. Thus, provided that the total area of all heated rooms in the house is 170 m2, a 17 kW boiler is required. But don’t forget about additional coefficients.

Thus, by adding up all the obtained coefficients, we can conclude that we need to add another 105% to the calculated power. In total we get almost 35 kW. This is quite a lot, but these are just approximate calculations. For more accurate calculations, we suggest using online calculator.

Calculation of an expansion tank for heating a two-story houseFor many this is a minor issue. In fact, let's think about what will happen if:

- There is not enough water in the expander. In this case, regardless of whether the heating is installed open or closed, when cooling, naturally, the coolant decreases in volume, which leads to aeration, in other words, to airing of the system. What happens in this case was described above;

- Too much water (small expansion tank) - water expands when heated and either overflows from the top (open system) or is squeezed out through the emergency valve (closed). Further, the system cools down, there is less water and... see previous.

Thus, these calculations are also very important. Typically, the volume of the expansion tank is 10% of total number liquids in the system. We suggest you, again, use an online calculator. After all, it is much simpler and faster.

First, let's consider a heating system based on popular wall-mounted double-circuit boilers with a power of up to 35 kW, in which the second circuit is aimed at providing hot water supply. These boilers have four pipes: two of which are connected to the heating system, and the other two to hot water supply. The boiler has its own circulation pump and expansion tank, and it would seem that it is enough to simply mount the boiler on the wall, supply gas to it, connect the water supply, hot water supply and heating pipes, and you can start the system. And this is true, but only if there is one heating circuit, for example, a radiator. But what needs to be done if, in addition to the heating circuit in the house, you also want to have “warm floors”, fortunately, the boiler power allows it?

The temperature of the coolant in the heating system and the “warm floor” system is different, so it’s easy to connect two various systems heating using tees to the supply pipe from the boiler is possible, but you need to come up with a scheme for equalizing the pressure differences in two different heating rings. In principle, this is not so difficult, but without having engineering knowledge in the field of heating engineering, you can do it easier - use a system of primary-secondary rings with a hydraulic manifold, which in this case also acts as a hydraulic pressure equalizer. This technique is widely known in heating engineering; such an equalizer is called an “arrow”. “Strelka” ensures a constant flow of coolant through the boiler, which has a beneficial effect on its long-term operation.

We take a ready-made hydrocollector, for example, “element-Micro” from the company “Gidromontazh” and connect it to the boiler, and “place” a radiator heating system and a “warm floor” system on the outlet pipes (Fig. 54). That's all the boiler piping.

Rice. 54. Wiring diagram for a wall-mounted boiler

If it is necessary to install several “warm floor” circuits, a conventional collector is also connected to the hydrocollector (Fig. 55), the main thing is that the total coolant flow in the secondary rings does not exceed the flow in the boiler. In other words, the boiler can produce full power with its pump, rotating hot water through the primary ring (through the hydrocollector and its own circuit), and consumers (secondary rings) should not pump out more hot water from the hydrocollector than it can produce. Otherwise, water will, of course, be present in the circuits, but the boiler will not have time to heat it. The power of the secondary rings is calculated based on the volume of the coolant, by setting the speed of movement of the coolant in the heating circuits, and by selecting the length and internal diameter of the pipes. The sum of all volumes of coolant flowing through the secondary rings in one hour should not exceed the volume of coolant supplied by the boiler in the same hour.

Rice. 55. Increasing the number of consumers for piping a wall-mounted boiler

If a simpler boiler is used, for example, a floor-standing one, in which there is no hot water supply circuit, expansion tank, automatic air vent and circulation pump, then these devices must be included in the heating circuit (Fig. 56).

Rice. 56. Heating system with vertical hydrocollector

With an increase in the number of consumers, this circuit can also be changed by including ordinary collectors in its circuit (Fig. 57). Please note that in this case, as in the case of the circuit shown in Figure 55, the number of secondary rings was not increased, it remained the same. One of the secondary rings was simply replaced with a two-pipe manifold system. It is this combination of heating systems with primary-secondary rings and conventional systems heating (collector, two- or one-pipe) and is called a combined heating system.

Rice. 57. Heating system with a vertical hydrocollector with an increase in the number of consumers

How they will work combined systems? Let us assume that in the secondary rings the four- or three-way mixers are in the closed position, that is, the secondary rings do not send a request for coolant. In this case, the coolant is heated in the boiler and, forced by the circulation pump, “spinning” in the primary ring - the hydrocollector. Water enters the boiler at approximately the same temperature as it left it. This has a very good effect on the operation of the boiler: there is no thermal shock, there is no large pressure drop. All modern boilers They are equipped with automatic equipment that measures the temperature of the coolant at the supply; since the water enters the boiler hot, there is almost no need to heat it up. The automation gives an order to the boiler burner and it reduces the flame height or completely turns off the burner. The boiler operates in economical mode. Next, the coolant circulating through the secondary ring cools down and the mixer opens - a command to request heat follows. The circulation pump of the secondary ring begins to pump out hot water from the hydrocollector through the mixer and discharge cooled water into it. The return flow, mixing with water in the hydrocollector, enters the boiler. The temperature sensor on the boiler detects a drop in temperature and immediately increases the burner flame. Thus, the more requests for heat from the secondary rings, the more the boiler will heat the water and, conversely, if there are no requests for heat, the boiler goes into an economical mode, until the burner is completely turned off.

For floor-standing boilers with a power of up to 50 kW, you can use the Kompakt hydrocollector from the Gidromontazh company, mounted on a special steel module, which is attached to the wall and floor (Fig. 58). This design uses an "extendable" primary ring with soft hot water heating priority. When the boiler is full hot water, the four-way mixer is in the closed position, the coolant, driven by the circulation pump of the primary ring, flows through both sections of the hydraulic collector and returns to the boiler. When the hot water supply is turned on, the boiler sends a request for heat and the mixer opens, so the primary ring seems to lengthen and already includes the boiler. The boiler automation is configured in such a way that it allows you to configure water heating in “hard”, “soft” and “parallel” modes. In other words, when “extending” the primary ring, the boiler can have priority over other heat consumers or work in parallel with them.

Rice. 58. Heating system with horizontal hydrocollector. Module "Hydro-Compact" with installed system automation and pumping and mixing groups

Like previous schemes, the heating system on compact hydrocollectors can be expanded to connect additional consumers (Fig. 59). To do this, special inserts or conventional collectors can be connected to the hydraulic manifold using a two-pipe scheme. If necessary standard scheme may not be expanded, but rather reduced.

Rice. 59. Increasing and shortening the heating system on hydro-Compact hydrocollectors

Agree that not everyone will use a scheme designed for a boiler power of up to 50 kW, capable of heating a house with an area of up to 500 m². However, it is necessary to clarify that hydraulic collectors designed for such power can be used at lower thermal loads. But we repeat once again that when purchasing hydrocollectors, it is necessary to compare their open cross-section with the coolant flow rate from the boiler, so that the speed of water movement through the collector is within normalized limits. For weak boilers, the collector should be chosen smaller, for powerful ones - larger. For example, for a boiler with a capacity of 30 kW, the coolant flow rate is 1.8 m³/h (30 l/min), if we take the coolant movement speed through the collector to be 0.3 m/s, then the open cross-section of the collector should be: f lc = Q/( 3600×V) = 1.8/(3600×0.3) = (m³/h)/(m/s) = 1.8×(100³ cm³/h)/3600×0.3×(100 cm/ c) = 1800000/108000 = (cm³/s)/(cm/s) = 16 cm², this can be a box with dimensions 2×8 or, for example, 3×5.5 cm. If a collector of the same cross-section is taken for the boiler with a power of 50 kW, then the speed of fluid movement in it will be (we’ll skip the calculations) 5.2 m/s, that is, the cross-section of this collector is not enough and it must be increased. But if the boiler power is less, for example, 15 kW, then the speed of the coolant in the collector will be 0.26 m/s, which corresponds to the standards - this hydraulic collector is suitable for a boiler of this power.

Rice. 60. Heating system with horizontal hydrocollector. Module "Hydro-Compromise" with installed automation system and pumping and mixing groups

In heating systems with a power of more than 50 kW, a pressure equalizer (other names: hydraulic separator or “arrow”) must be installed in the piping circuit (Fig. 60). In this scheme, the primary ring consists of a boiler circuit and a hydraulic equalizer, in which the coolant circulates under the action of the boiler pump. The hydraulic equalizer (Fig. 61) ensures unhindered guaranteed circulation through the boiler, as well as slowing down the flow and reducing the pressure drop between the forward and return lines of the collector. When heat is requested from consumers, the coolant circulates through the boiler, hydraulic equalizer, hydraulic collector and the corresponding consumer ring. Heat is removed from the secondary rings from the upper chamber of the collector.

Rice. 61. Hydraulic leveler

For powerful heating systems with boilers from 50 kW, hydraulic levelers with separating grids and magnetic plates are used. The hot coolant from the boiler supply pipe, driven by the primary circulation pump, flows into the hydraulic equalizer and, colliding with the partition, enters the upper part of the housing. There is another partition here that separates the coolant, separating the air from it. Next, the hot water is mixed with cooled water received from consumers and supplied to the heating system. The coolant coming from the heating system collides with magnetic plates, which attract metal particles and serve as a brake for the cooled water; here the water slows down its flow and discharges sludge into sediment. This is also where hot water return from the boiler supply is mixed with the cooled water - the heated return coolant enters the boiler. Thus, the hydraulic leveler simultaneously serves as an air separator, mixer, brake and settling tank.

For weak heating systems, up to 50 kW, a hydraulic equalizer is used, which is no less functional, but of a simpler design. This is usually the capacity rectangular shape with a clear cross-sectional area ensuring a reduction in coolant velocity from 0.2 to 0.4 m/s. Due to the low speed, sludge falls out of the coolant and settles at the bottom of the hydraulic equalizer and air is released, which is released by automatic air vents. 1–3 perforated partitions are installed in the center of the hydraulic leveler (in the mixing chamber), without sealing around the perimeter. If you cut such a hydraulic equalizer, it very much resembles a car muffler, and it works approximately the same way.

One of the most popular designs based on hydrocollectors is the circuit on two half-rings (Fig. 62), which is a development of the circuit shown in Figure 56. The heating system on two half-rings allows you to expand the number of consumers (secondary rings), but with the condition that the loads on the half-rings will be approximately the same. The scheme is used with boilers of any capacity; if one boiler is not enough, then a second boiler can be included in the scheme.

Rice. 62. Heating diagram of two half-rings of the copyright holder, prohibited.

Contacts.

Autonomous heating system for private country house– in itself is a very difficult project in terms of planning and practical implementation. It is necessary to take into account a lot of nuances, carry out the necessary thermal calculations, and correctly select all the equipment required for the system by type and technical specifications, decide on the schemes for its installation and laying the necessary communications, correctly carry out the installation and carry out commissioning work. All this is done to ensure that the creation in residential premises the most optimal microclimate was fully combined with the ease of operation of the heating system, the reliability of its operation and, without fail, with the highest possible efficiency.

Well, if a heating scheme for a 2-story private house is being developed, then the task becomes even more difficult. Not only is the number of premises and the length of thermal routes increasing. It is important to achieve the necessary uniform distribution of heat throughout all rooms, regardless of what floor they are located on and what area they have.

This publication will examine the main elements of the heating system of a private house and provide several schemes that have already been tested in operation. Of course, it is necessary to mention the advantages and disadvantages of each option.

What heating systems are there?

First of all, it is necessary to consider and compare two basic schemes - open and closed heating systems. What is their main difference?

A coolant circulates through the pipes - a liquid with high heat capacity, transferring thermal energy from the place of heating - the heating boiler, to heat exchange points - radiators, convectors, underfloor heating circuits, etc. Like any physical body, a liquid has the property of expanding when the temperature increases. But, unlike, for example, gases, it is an incompressible substance, that is, it is necessary to provide a place for the excess volume that appears so that the pressure in the pipes, according to the laws of thermodynamics, does not increase to critical values.

For this purpose, an expansion tank is provided in any heating system with liquid coolant. Its design and installation location determine the division of heating systems into closed and open.

- The principle of an open heating system is shown in the diagram:

1 – heating boiler.

2 – supply pipe (riser).

3 – open type expansion tank.

4 – heating radiators.

5 – return pipe

6 – pump unit.

The expansion tank is an open container of factory or handicraft production. It has an inlet pipe that is connected to the supply riser. It can be supplemented with pipes to prevent overflow when filling the system, to replenish the lack of coolant (water).

The main condition is that the expansion tank itself must be installed at the highest point of the system. This is necessary, firstly, so that excess coolant does not simply overflow outward according to the rule of communicating vessels, and secondly, it serves as an effective air vent– all gas bubbles formed during the operation of the system rise to the top and freely escape into the atmosphere.

No. 6 in the diagram shows the pumping unit. Although very often open-type systems are organized according to the principle of natural coolant circulation, installing a pump never hurts. Moreover, if you tie it correctly, with a bypass loop and shut-off valves, this will make it possible, as necessary, to switch from natural circulation to forced circulation and back.

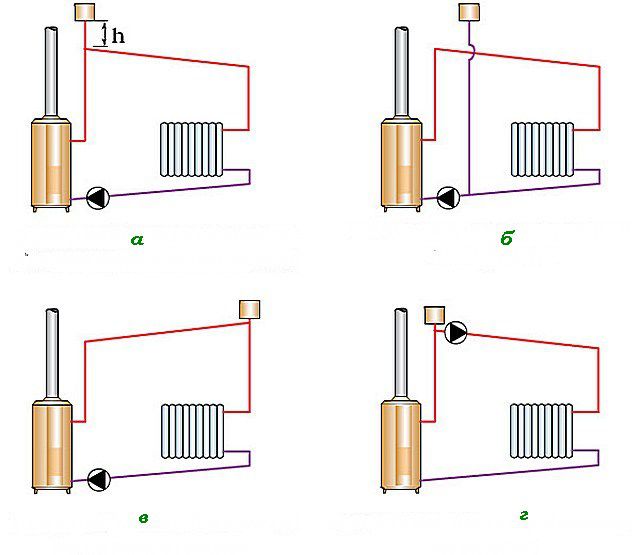

By the way, installing an open expansion tank at the top point of the supply pipe is not at all a mandatory rule. There are possible options here, the choice of which is made based on the specific features of a particular heating system:

a – the tank is located at the highest point of the main supply pipe leaving the boiler. One might say - a classic version

b – the expansion tank is connected by a pipe to the “return”. Sometimes you have to resort to this arrangement, although it has a significant drawback - the tank does not fully perform its functions air vent, and in order to avoid gas locks, such a device will have to be installed with special taps on risers or directly on heating radiators.

c – the tank is installed on the far supply riser.

d – a rare location of the tank with the pump unit directly after it on the supply pipe.

- Below is a diagram of a closed type heating system:

The numbering of common elements is preserved by analogy with the previous scheme. What are the main differences?

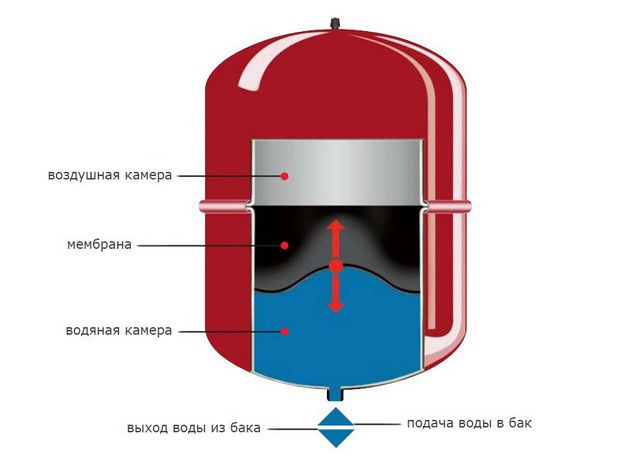

The system has a sealed expansion tank (7), which has a special design. It is divided by a special elastic membrane into two halves - a water and an air chamber.

This tank works very simply. With thermal expansion of the coolant, its excess enters the closed tank, increasing in volume water chamber due to stretching or deformation of the membrane. Accordingly, in the opposite air chamber pressure increases. As the temperature drops, air pressure pushes the coolant liquid back into the system pipes.

Such an expansion tank can be installed almost anywhere in the heating system. Very often it is located in close proximity to the boiler on the return pipe.

Since the system is completely sealed, you should protect yourself from a critical increase in pressure in it in emergency situations. This necessitates another element - a safety valve, set to a certain response threshold. Typically this device is included in so-called "security group"(on the diagram - No. 8). Its standard equipment includes:

"Security group" assembled

1 – control and measuring a device for visually monitoring the state of the system: a pressure gauge or a combined device - a pressure gauge-thermometer.

2 – automatic air vent.

3 – safety valve with preset upper threshold pressure or with the ability to independently regulate this parameter.

The security group is usually placed in such a way that the state of the system can be easily monitored. Often it is installed right next to the boiler. In this case, the upper sections of the heating system will require additional air vents on risers or on radiators.

Systems with natural and forced circulation

The principles of natural and forced circulation have already been mentioned in passing, but it is worth taking a closer look at them.

- The natural movement of coolant along heating circuits is explained by the laws of physics - the difference in density of hot and cooled liquid. To understand the principle, let's look at the diagram:

1 – point of primary heat exchange, boiler, where the cooled coolant receives heat from external energy sources.

2 – pipe for supplying heated coolant.

3 – secondary heat exchange point – heating radiator installed in the room. It should be located above the boiler by an amount h.

4 – return pipe going from the radiators to the boiler.

The density of a hot liquid (Pgor) is always significantly less than that of a cooled liquid (Rohl). The heated coolant, therefore, cannot have any significant effect on a denser substance. Therefore, we can conditionally remove the upper “red” part of the diagram and consider the processes in the “return” pipe.

The result is “classical” communicating vessels, one of which is located higher than the other. Such a hydraulic system always strives for balance - to ensure equal levels in both vessels. Due to the excess of one over the other in the return pipe, a D.C. liquid towards the boiler. Such a naturally created pressure with proper planning of the wiring is sufficient for the general circulation of the coolant through a closed heating circuit.

The greater the excess of radiators over the boiler (h), the more active the natural movement of liquid is, but it should not exceed 3 meters. Very often, in order to achieve an optimal location, the boiler is installed in the basement or basement. If this cannot be done, then they try to slightly lower the floor level in the boiler room.

To facilitate and stabilize natural circulation, it is also assisted by gravity - all circuit pipes are placed with a slope (from 5 to 10 mm per linear meter).

- The forced circulation system requires the mandatory installation of a special electric pump of the required capacity.

As already mentioned, the system can be combined - a properly connected pump will allow switching from one circulation principle to another. This is especially important in cases where the electricity supply in the area where you live is not stable.

The optimal location for the pump is considered to be the return pipe in front of the boiler entrance. This is certainly not a dogma, but in this area he will be less influenced by high temperatures coolant and will last longer. Nowadays, they are increasingly being purchased heating boilers, which structurally already contain a circulation pump with the required parameters.

Advantages and disadvantages of various systems

First of all, it should be noted that there is no clear division of systems according to the two mentioned parameters at once. Thus, an open system can operate on the principles of both natural and forced circulation, depending on its design features. The same can be said to a certain extent about a closed hermetic system, although already- With certain assumptions.

But if we look at the projects presented on the Internet, we will notice that an open system often involves natural circulation or a combined one, with the possibility of switching. Closed heating circuits most often provide for the installation of forced circulation - this way they work more correctly and are easier to adjust.

So, let's look at the main advantages and disadvantages of both systems.

In the beginning - oh merits open system with natural circulation.

- In an open type system, the expansion tank performs several functions at once.

— This scheme does not require the installation of a safety group, since the pressure can never reach critical values.

— Installation of the expansion tank at the highest point on the supply pipe ensures spontaneous release of accumulated gas bubbles. Most often, this is quite enough, and installing additional air vents not required.

- The system is extremely reliable in terms of operation, as it does not contain complex components. In fact, its “life” is determined only by the condition of the pipes and radiators.

- There is no complete dependence on the power supply, no electricity is consumed.

- The absence of electromechanical components means silent heating operation.

- Nothing prevents you from equipping the system with forced circulation.

- The system has an interesting property of self-regulation - the intensity of circulation of the coolant depends on the rate of its cooling in the radiators, that is, on the air temperature in the rooms. The higher the heating, the lower the flow rate. This often allows the system to be balanced without the use of complex adjustment devices.

Now - about her shortcomings:

- The rule for installing an expansion tank at the highest point often leads to the need for its location in the attic. If the attic is cold, then reliable thermal insulation of the tank will be required - to prevent serious heat losses and to avoid freezing in low winter temperatures.

- An open tank does not prevent the coolant from contacting the atmosphere. And this, in turn, entails two negative aspects:

— Firstly, the coolant evaporates, which means you need to monitor its level. In addition, this limits the owners in choosing a coolant - the evaporation of antifreeze entails certain material costs. Moreover, the concentration of chemical components may also change, and for some boilers (for example, electrolytic ones) this is unacceptable.

“Secondly, the liquid is constantly saturated with oxygen from the air. This leads to the activation of corrosion processes (steel and aluminum radiators are especially affected). And the second negative is increased gas formation during the heating process.

Aluminum radiators for open heating systems are of little use

- Such a system causes certain difficulties during installation - it is necessary to maintain the required level of slope. In addition, pipes will be required different diameters, including large ones, since for each section with natural circulation it is necessary to maintain the required cross-section. This circumstance also complicates installation and leads to significant material costs, especially when using metal pipes.

- The capabilities of such a system are very limited - if the distance from the boiler is too great, the hydraulic resistance of the pipes may be higher than the natural liquid pressure created, and circulation will become impossible. By the way, this completely excludes the possibility of using “warm floors” without special additional equipment.

- The system is very inert, especially during a “cold start”. A serious starting “impulse” is required, that is, starting at high power to ensure the start of fluid circulation. For the same reasons - there are certain difficulties in finely balancing the system across floors and rooms.

Now let's look at closed system with forced circulation.

Her dignity:

- Provided the circulation pump is correctly selected, the system is not limited by the number of floors of the building or its plan size.

- Forced circulation ensures faster and more uniform heating of radiators during startup. It is much easier to make fine adjustments.

- The coolant does not evaporate and is not saturated with oxygen. There are no restrictions on the type of liquid or the type of radiator.

- The tightness of the system prevents air from entering pipes and radiators. Gas formation in the liquid gradually disappears over time and is easily eliminated air vents.

- It is possible to use pipes of smaller diameter. When installing them, no slope is required.

- The expansion tank can be installed in any place convenient for the owners in a heated room - the likelihood of it freezing is completely eliminated.

- The temperature difference at the boiler outlet and in the “return” with stable heating operation is significantly less. This circumstance significantly increases the service life of the equipment.

- This system is the most flexible in terms of the use of heating devices. It is suitable for “classic” radiators, and for convectors and “heat curtains”, wall-mounted or hidden, and for “warm floor” circuits.

Disadvantages not much, but they are still there:

- For correct operation, it will be necessary to carry out a preliminary calculation of all components of the system - boiler, radiators, circulation pump, expansion tank, in order to achieve complete consistency in their functioning.

- It is impossible to do without installing a “security group”.

- Perhaps the most important drawback is the dependence on the stability of the electricity supply.

This will most likely require purchasing and installing sources uninterruptible power supply(if the design does not allow for the possibility of switching to natural circulation with a non-volatile boiler).

Wiring diagrams in a two-story house

How to route heating pipes throughout a two-story house? There are several schemes, from the simplest to the quite complex.

First of all, you need to decide whether the system will be one pipe or two pipe.

- An example of a one-pipe system is shown in the diagram:

One-pipe system is the most imperfect

The heating radiators seem to be “strung” onto one pipe, which is looped from the outlet to the entrance to the boiler and through which both the supply and removal of coolant are carried out. The obvious advantages of such a scheme are its simplicity and minimum consumption materials during installation. Unfortunately, this is where its advantages end.

It is quite obvious that the fluid temperature drops from radiator to radiator. Thus, in rooms located closer to the boiler room, the temperature of the batteries will be significantly higher than in rooms located further away. Of course, this can be compensated to some extent by a different number of heating sections, but this is seen only in small houses. Considering that the article is about a two-story building, then such a scheme is unlikely to be the optimal solution.

Some problems are solved by installing a single-pipe system - “Leningradka”, the diagram of which is shown in the figure below. The input and output of each battery in this case are connected to each other by a bypass jumper, and heat loss as it moves away from the boiler is no longer so significant.

The Leningradka scheme eliminates some of the problems

"Leningradka" lends itself to even greater modernization. So, you can install a control valve on the bypass. The same valves can be installed on one or even both radiator pipes (shown by arrows). This immediately opens up wide possibilities for fine-tuning the heating system for each room individually. There is access to each radiator - if necessary, it can simply be turned off or removed for replacement, without at all interfering with the functionality of the entire circuit.

Improved "Leningradka" with shut-off and balancing valves

By the way, with its flexibility, simplicity, and low consumption of pipes, the Leningradka has gained enormous popularity - it can often be found in one-story houses(especially with a significantly large wall perimeter), and in high-rise buildings. It is quite suitable for a two-story mansion.

And yet it is not without its shortcomings. The possibility of connecting underfloor heating circuits, heated towel rails, etc. to it is completely excluded. In addition, the relative position of rooms, doors, exits to balconies and etc.. It is not always possible to stretch pipes along the entire perimeter, and the Leningradka must ultimately be a closed ring.

- A two-pipe heating system is much more advanced. Although it will require more materials and will be more difficult to install, it is still preferable to stick with it.

In essence, it consists of supply and return pipes running parallel to each other. The radiators are connected by pipes to each of them. An example is shown in the diagram:

The radiators are connected to the supply and return pipes in parallel, and each of them in no way affects the operation of the others. Each “point” can be very precisely adjusted individually - for this, bypass jumpers (item 1) are used, on which balancing valves (item 2) or even three-way control valves-temperature regulators (item 3) can be installed, constantly maintaining a stable temperature heating of a specific battery.

The advantages of a two-pipe system are undeniable:

- The general heating temperature at the inlet to all radiators is maintained.

- The total pressure loss from the hydraulic resistance of the pipes is significantly reduced. This means that a lower power pump can be installed.

- Any of the radiators can be turned off or even removed for repair or replacement - this will not affect the system as a whole.

- The system is very versatile, and it is quite possible to connect any heat exchange devices to it - radiators, heated floors (through special manifold cabinets), convectors, fan coil units, etc.

Perhaps the only drawback of the two-pipe system is its consumption of materials and complexity of installation. In addition, there will also be an increase in calculations when designing it.

One of the complex, but very effective options for a two-pipe system is collector or radial wiring. In this case, two individual pipes are stretched from two collectors - supply and return - to each radiator. This, of course, greatly complicates the installation - incomparably more material will be required, and it is more difficult to hide the collector wiring (usually it is placed under the floor surface). But the adjustment of such a circuit is highly accurate and can be carried out from one place - from a manifold cabinet equipped with all the necessary adjustment and safety equipment.

By the way, on the scale of a two-story building, it is very often necessary to resort to a combination of connection schemes, two-pipe and one-pipe, in certain areas, where it is more profitable and easier from an installation point of view, and does not affect the overall heating efficiency.

Next important question– floor-by-floor pipe distribution.

Two main options are used. The first is a system of vertical risers, each of which provides heat to both floors at the same time. And the second is a scheme with so-called horizontal risers (it would be more accurate to call them “loungers”), in which each floor has its own wiring.

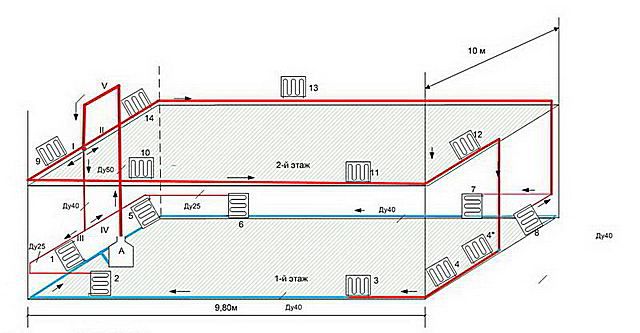

An example of wiring with risers is shown in the figure:

This option presents risers with bottom wiring. From the horizontal beds of the first floor, the supply pipes go up, and the “returns” return here. In this case, it would be advisable to place at the upper end of each riser air vent.

There is another option - risers with top supply. In this case, the supply pipe leaving the boiler immediately rises up, already on the second floor or even in the upper technical room, vertical risers are connected to it, penetrating the building from top to bottom.

The scheme with risers is convenient if the floor plans are largely the same and the radiators are located one above the other. In addition, this option will be optimal when the decision is made to apply open system heating with natural circulation - in this case the most important task is to minimize the length of horizontal (sloping) sections, and the risers do not provide serious resistance to the flow of coolant from top to bottom.

An example of such a system is shown in the following diagram:

A common large-diameter supply pipe rises from the boiler (item 1), which enters a large-volume expansion tank (item 3), located at the top point of the system approximately in the center between the risers. The solution is quite interesting - the expansion tank simultaneously plays the role of a kind of collector, from which supply pipes radiate in all directions to the vertical risers. Radiators of both floors are connected to the risers (item 4), the precise adjustment of which is carried out by special valves (item 5).

As already mentioned, systems with natural circulation are quite demanding in terms of accurate selection of nominal pipe diameters. These are shown in the diagram by letter designations:

a - dy = 65 mm

b - dy = 50 mm

c - dy = 32 mm

d - dy = 25 mm

e - dy = 20 mm

The disadvantage of a system with risers is considered to be its rather complex execution - it will be necessary to organize several interfloor transitions through the ceiling. In addition, vertical risers are almost impossible to “remove from sight” - this can be important for those owners who have decorative finishing rooms are a priority.

An example of a two-pipe system with individual wiring for each floor is shown in the following diagram:

Here there are only two vertical risers located side by side - for submissions and for “return”. This principle looks quite rational from an installation point of view; it allows you to completely turn off an entire floor if for some reason it is temporarily not in use. In addition, the underground installation of pipes makes it possible to almost completely hide them from view, closing flooring and leaving only the inlet and outlet pipes of the radiators outside.

In fact, each floor can have its own layout, depending on the layout of the rooms. There are many options for the location of pipes and connection of radiators for floor-to-floor wiring. Some of them are shown in the diagram, where a conditional division is made into three floors.

- Conventional first floor - a simple two-pipe “dead-end” type wiring with counter-movement of the coolant was used. The scheme has its own characteristics. The supply and return pipes are mounted parallel to each other until the very end of the branch (there can be several branches - two are shown in the diagram). The diameter of the pipes gradually narrows from radiator to radiator. It is very important to provide balancing valves, otherwise radiators installed closer to the boiler can short-circuit the coolant flow through themselves, leaving subsequent heat exchange points unheated.

- Shown on the second floor the so-called "loop"Tikhelman". A very successful scheme in which the supply and return flows go in the same direction. A diagonal connection of the batteries is provided - inlet from the top and outlet from the bottom - this is considered optimal from the point of view of heat transfer. Very often, with such a scheme, radiator balancing is not even required. But there is an important condition - the pipes must be of the same diameter.

- The third floor is equipped according to the already mentioned collector scheme. From the two collectors there is an individual wiring to each radiator with pipes of strictly the same diameter. The system is the most convenient to fine-tune. This is what should be used if you plan to install underfloor heating circuits. It is desirable that the collectors be located as close as possible to the center of the floor - to maintain approximate proportionality to the lengths of all “rays” extending from them.

There are many other options for wiring in a two-story house, and it will not be possible to consider all of them on the scale of one article. In addition, a lot depends on the “geometry” and architectural features of the house, and it is simply impossible to develop “universal recipes”. In such matters, it is better to trust experienced specialists - they will help you choose the right scheme for specific conditions.

Video: useful information on radiator heating schemes

Basics of calculating the main elements of a heating system

It is not enough to decide on the type of heating system and pipe laying scheme - you need to clearly define the operational parameters in order to correctly purchase and install its main necessary elements - heating boiler, heating radiators, expansion tank, circulation pump.

How to calculate the required boiler power?

There are many methods for calculating this indicator. Very often you can find recommendations to proceed from total area heated rooms in the house, and then carry out calculations at the rate of 100 W per 1 m².

Such a recommendation has the right to life, and can give a general idea of the required thermal power. However, it is more suitable for very average conditions, and does not take into account a whole range of important features, which directly affect heat loss at home. Therefore, it is better not to be lazy and carry out the calculation more carefully.

The best way to approach the matter is as follows. To begin with, draw a table in which you will list, floor by floor, all the rooms where the installations will be installed. heating devices. For example, it might look like this:

| Room | Area, m² | External walls, quantity, included: | Number, type and sizes of windows | External doors (to the street or to the balcony) | Calculation result, kW |

|---|---|---|---|---|---|

| TOTAL | 22.4 kW | ||||

| 1st floor | |||||

| Kitchen | 9 | 1, South | 2, double glazing, 1.1×0.9 m | 1 | 1.31 |

| Hallway | 5 | 1, S-W | - | 1 | 0.68 |

| Dining room | 18 | 2, C, B | 2, double glazing, 1.4 × 1.0 | No | 2.4 |

| … | … | ... | ... | ... | ... |

| 2nd floor | |||||

| Children's | ... | ... | ... | ... | ... |

| Bedroom 1 | ... | ... | ... | ... | ... |

| Bedroom 2 | ... | ... | ... | ... | ... |

| … | … | ... | ... | ... | ... |

Having a house plan before your eyes and having information about the features of your home, walking around it, if necessary, with a tape measure, it will not be difficult to collect all the necessary data for calculations.

Then all that remains is to sit down to do the calculations. But we will not bore readers with a long formula and tables of coefficients. In a nutshell, the calculation is carried out based on the already mentioned standard of 100 W/m². But this takes into account many corrections that affect the required power heating system to maintain a comfortable temperature and compensate for heat losses. All these correction factors are included in the calculator offered to your attention - you just need to enter the requested data and get the result.

Calculator for calculating the required thermal power of a heating boiler

The calculation is carried out for each room separately and the result is entered into the table. And then all that remains is to find the amount - this will be the minimum thermal power that the heating boiler should produce. Naturally, when choosing a model, you can also include a “reserve”, about 20%.

Make sure that using the calculator, the calculation will take very little time!