Despite the fact that advanced space heating technologies are now widespread, a heating system with natural circulation is in great demand. First of all, this is due to the fact that it is easy to install, and if we also take into account the instability of supplying the private sector with electricity, then the popularity of such an autonomous heating system becomes clear.

How does this work

It’s worth saying right away that thanks to a special device, the system operates without forced coolant circulation. The movement of water in the pipes occurs due to the fact that when cooled, the density of the water increases, and it flows to the boiler through pipes installed at a slope, pushing the heated water out of it.

Although a heating system with natural circulation can work without a pump, it is still better to install one. When the pump is turned on, the coolant flows through the pipes faster, therefore, the room warms up faster.

When leaving the boiler, the water enters the accelerating manifold, reaches the top point through it and, through pipes installed at an angle from the boiler, cools and continues its path in a circle.

Disadvantages and advantages

Let's talk about the disadvantages first. This approach will help you decide whether such a heating system is right for you.

- If the system does not have a pump, then you need to wait quite a long time until the hot water reaches the radiators and passes through them.

- Uneven heating of heating radiators. This is due to the same nuance - hot water on top and cold water below.

- Installation is carried out using more expensive large diameter pipes.

- It is necessary to install an open expansion tank, as a result of which water evaporates and must be periodically added to the system. Installing a closed expansion tank may impair system performance.

- The design of the room suffers.

- The slope of the pipes must not be disturbed, even if it is necessary to bypass the doors.

- The system should have as few turns as possible.

- When planning a heating system without a pump, you need to correctly determine the level of location of the batteries, expansion tank and boiler, which should be installed at the lowest point.

Advantages

- Electrical independence. Even if a pump is installed, if there is a power outage (or if the pump fails), the heating system continues to operate.

- Installation and further maintenance do not require special skills.

- Quiet operation.

Types of systems

As already mentioned, in a gravity heating system there should be no differences in height, otherwise it simply will not work. For this reason, several contours can be made.

Single-circuit

Everything is very clear here - one pipe goes from the boiler, and the other to it, and batteries are connected between them. The presented diagram will help you figure this out.

A single-circuit system can also be single-pipe, only in this case it is necessary to take into account the fact that each subsequent battery in a gravity-flow system will be significantly colder than the previous one.

Dual-circuit

Double-circuit systems may differ in the direction of movement of the coolant:

- With oncoming traffic.

- With passing traffic.

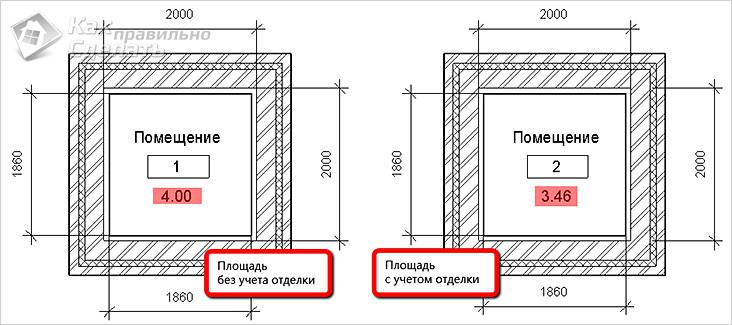

In order not to have to deal with rework later, it is important to find out at the planning stage what the power of the battery (or batteries) that will be installed in a particular room should be. To do this, you can use one of two methods.

By volume

More accurate data can be obtained taking into account the volume of the room. We take measurements and, having received data on the height, width and length of the room, multiply them together, and multiply the result by 40 W. Taking into account the structural features, we introduce a correction factor. For:

- one-story private house with an uninsulated attic - 1.5;

- rooms with an insulated wall – 1.1;

- rooms with uninsulated walls – 1.3;

It is important to consider the number of doors and windows.

- If there is front door, then you need to add another 150–200 W to the resulting figure.

- If the windows are small and energy-intensive, then each will require another 70 W.

- For large or uninsulated windows, add 100 W.

By area

When calculating the number of batteries by room area, an average indicator is used - 1 kW per 10 m 2. The power of a heating boiler purchased for a home is calculated using the same principle.

Let's look at an example of how calculations can be made.

- There is a house with internal dimensions of 9 × 8 m. We multiply the width by the length and get an area of 72 m 2.

- Divide 72 m2 by 10 (1 kW per 10 m2), and we get 7.2 - this is the boiler power in kW.

- Now we find out the battery power for a room of 2x4 m.

- The area turned out to be 8 m2.

- Using the same calculations as for the boiler, we get the figure 0.8 - battery power in kW.

Now let's make adjustments for climate zones. Let's look at the coefficients:

- IN Southern regions – 0,8–0,9.

- For the Far North – 1.5–2.

- In the zone Middle zone – 1,2–1,4.

In our example, a 7.2 kW boiler was required. Taking into account the coefficient, we will calculate the final data for the Middle Band:

- 7.2×1.4=10.08.

- Considering that the boiler must have a power reserve, we purchase heating device power 12–15 kW.

- In the same way, we approach the calculations of battery power for the room used in the example: 0.8 × 1.4 = 1.12 kW. We round up and get 1.2 kW.

The battery power is indicated in the product data sheet. If you are not sure of the correctness of your calculations, then purchase a more powerful radiator by installing a thermostat on it.

Installation

- As already mentioned, the boiler should be installed at the lowest point.

- No pipe should be located below the level of the return inlet to our heating device. Neglecting this requirement will lead to a significant deterioration in the performance of the heating system.

- The location of pipes and radiators is marked on the walls.

- The radiators are hung - their position is checked with a building level.

- An accelerating manifold is mounted from the boiler supply pipe. This should be a large diameter pipe.

- An open expansion tank is installed at the top point. If it is located in the attic, then the container and pipeline must be thoroughly insulated.

- The pipes are fastened with a slope of 1 cm per linear meter pipes. If it is not possible to adhere to this norm, then you can reduce the difference to 0.5 cm, but not less. It must be taken into account that as the pipe slope decreases, the efficiency of the entire heating system decreases.

- IN in the right place The pipe going to the radiator is inserted. In a metal pipeline, the outlet can be welded or connected through a tee. When working with plastic pipes you need to use fittings, soldering them, not forgetting about taps and thermostats (if their installation is provided).

- At the lowest point of the system (usually near the boiler), you need to install an outlet with a tap - through it, water will be poured into the system.

Planning the manufacture of a gravity system in two-story house, you need to take into account that the coolant is supplied to the second floor, and then it is lowered through risers into radiators installed on the first floor.

All that remains is to fill the system with water, and, after checking it for leaks, heat the room without worrying that the electricity may be turned off.

Video

Watch a video on how to calculate natural circulation heating:

This video shows an example of natural circulation heating.

One of the simplest is a heating system with natural circulation. However, this simplicity, in the absence of proper experience in working with such systems, can “come out sideways” during operation.

Heating with natural circulation was widespread ten years ago in suburban areas. big houses and some apartments with individual heating. Now the market is being “conquered” by systems with forced coolant circulation, thanks to the opportunities they provide.

But let's talk about water heating with natural circulation.

Design features of the system

Natural circulation heating systems include:

- heating boiler that heats water;

- supply pipeline “supplying” hot water to heating devices (radiators);

- return pipeline through which water returns to the boiler;

- heating devices - radiators that give off heat to environment;

- , designed to compensate for the thermal expansion of the liquid.

Operating principle of the system

Water, heating up in the boiler, rises up the central riser and through the supply pipeline enters the heating radiators (heating devices), where it gives off part of its heat. Next, the cooled water again enters the boiler through the return pipeline and is heated again. Then the cycle is repeated, ensuring a comfortable temperature in the heated room.

To ensure natural circulation of the coolant (usually water) in the system, the horizontal parts of the pipeline are mounted with a slope of at least 1 cm per linear meter of the length of the horizontal section of the heating system.

Hot water, due to a decrease in its density when heated, rises up the central riser, squeezed out cold water, returning to the boiler. Then it spreads by gravity along the supply pipeline to the heating radiators. After “staying” in them, the water also flows by gravity back into the boiler, again squeezing upward the water already heated in the boiler.

Air that gets into the system with the coolant can create air lock in heating radiators, but, often, in such heating systems with natural circulation, air bubbles, thanks to the slopes of the pipeline, “travel” upward and exit into an open-type expansion tank (a tank in contact with atmospheric air).

The expansion tank is designed to maintain constant pressure in the heating system, due to the fact that it is filled with a volume of coolant that increases during heating, which then “releases” back into the system when the temperature of the liquid decreases.

Let's draw conclusions!

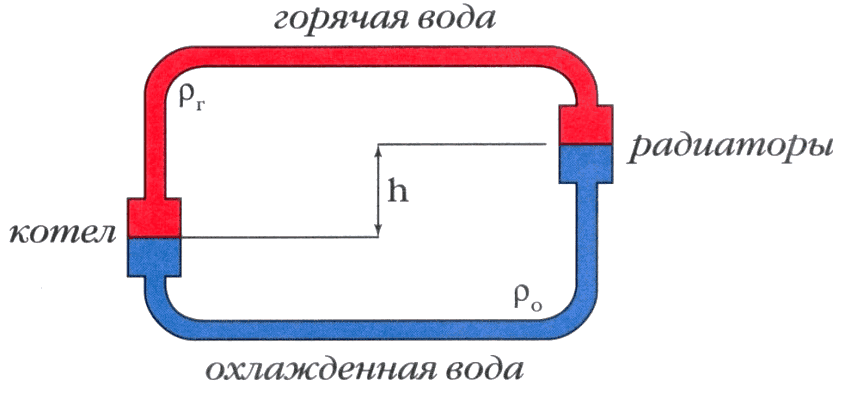

So! The rise of water in the system (riser to the supply pipe) is carried out due to the difference between the densities of the heated and cooled liquid. The movement (circulation) is also supported by gravitational pressure (return pipe).

When the coolant moves through a pipeline in a heating system with natural circulation, resistance forces act on the liquid:

- friction of liquid against pipe walls (large diameter pipes are used to reduce this);

- changing the direction of movement of liquid at turns, branches, channels of heating devices (radiators).

Basic physical parameters of a natural circulation heating system

Circulation pressure Рс - physical quantity, determined by the difference in height between the centers of the boiler and the lowest heating device (radiator).

The greater the height difference (h) and the difference in densities of heated (ρ g) and cooled (ρ o) liquids in the system, the better and more stable the coolant circulation will be.

R c =h(ρ o -ρ g)=m(kg/m 3 -kg/m 3)=kg/m 2 =mm.water column.

Let’s “look” for the reason for the appearance of circulation pressure in a heating system with natural circulation in the “wild” of the laws of physics.

If we assume that the temperature of the coolant in the heating system “jumps” between the centers of the devices (boiler and radiators), that is, the upper part of the system contains hotter water than bottom part systems.

Density (ρ g)(ρ g).

We cut off (mentally) the upper part on the circuit diagram and... What do we see? A familiar picture from school - two communicating vessels located on at different levels. And this will lead to the fact that liquid from a higher point, under the influence of gravitational force, will flow to a lower one.

Due to the fact that the heating system is a closed circuit, the water does not splash out, but simply strives to equalize its level, which leads to the heated water being pushed upward and to its further “independent gravitational” path through the heating system.

The conclusion is this! The fundamental indicator of the circulation pressure is the difference in the installation heights of the boiler and the last (lowest) radiator in the system. Therefore, in heating systems of private houses, boilers are located in basements whenever possible, observing maximum height at 3 m.

IN apartment options they try to “deepen” the boilers to the floor slab, accordingly “fireproofing” the “nest” for planting the boiler in the floor.

According to the formula given above, the circulation pressure is significantly influenced by the difference in the densities of cold and hot water in the system.

A heating system with natural circulation is a self-regulating system, that is, for example, when the heating temperature of the coolant increases naturally (see formula), the circulation pressure and, accordingly, water flow increase.

At low temperatures in a heated room, the difference in water densities is large and the circulation pressure is quite large. When the room is heated, the coolant no longer cools down as much in the radiators, and the difference in the densities of the heated and cooled coolant decreases. Accordingly, the circulation pressure decreases, reducing the “consumption” of water.

Is the air in the room cool? For example, someone opened the doors to the street. The density difference increased again, increasing the water pressure.

Disadvantages and advantages of natural circulation heating systems

The disadvantages of natural circulation include:

- Low circulation pressure, which determines the limited use of such heating systems - a small horizontal radius of action (up to 30 m).

- Greater inertia of the heating system, due to the large volume of coolant in the system and low circulation pressure.

- The likelihood of water freezing in, which is usually located in a cold (unheated) attic.

The main advantage of such systems is the energy independence of solid fuel boilers. That is, such systems can be used in homes where there is no power supply. The large inertia of the system due to the sufficiently large volume of coolant in the system can play as positive (something like thermal battery with an “extinguished” boiler), and a negative role - a significant time for changing the temperature of the system, especially at the start-up stage.

Types of heating schemes with natural circulation

Which heating system with natural coolant circulation will you choose? We hope it's correct!

Video: coolant circulation in the heating system

Reality and delusions.

Gravitational circulation is also colloquially called natural circulation. A system with gravitational circulation differs from a system with forced (pump) circulation in that circulation is carried out not under the influence of the force of an electric circulation pump, but under the influence of gravity.

The question may arise: “How can gravity force circulation?”

I'll try to explain it this way. Imagine that you placed on the left and right scales each an identical open canister, filled with water to the brim (and connected from below by a tube, i.e. communicating vessels). And then they began to heat the water in the left canister (even just in the rays of the Sun). As a result of heating, the water in the left canister will expand (at the same time it will decrease specific gravity, i.e. density), will become larger in volume. And since our canister was filled to the brim, some of the water will spill out onto the ground (in the heating system, this part of the water is not poured out, but is squeezed into the expansion tank, accumulating in it.).

Can you guess that the left canister will be lighter than the right? As a result, the left pan of the scale will rise up, and the right pan will fall.

If you now try to imagine that these canisters were suspended by a cable from a rotating block (a wheel with a hook) suspended from the ceiling. As long as the water in the canisters was the same temperature, both canisters weighed the same. When the water in the left canister heated up, due to the water pouring out of it onto the ground, this canister became a little lighter than the right one. It is clear that in this case the left canister will begin to rise upward, because the right canister turns out to be heavier and outweighs the left canister.

The same principle is used to implement gravitational circulation. Imagine that the left canister is a cauldron that is constantly heating. And the right canister is radiators in which the water continuously cools. Only the canisters are connected to each other by tubes and on the bottom and top in a ring. In heating, such a ring is called a circulation ring. Then it turns out that the right side of the motion ring always turns out to be heavier than the left side (while the boiler is heating).

The “overweighing” force (the amount of pressure) resulting from the difference in the weight of the left and right “canister” is called pressure in hydraulics. And under the influence of this force (gravitational pressure), it will continuously circulate from the boiler to the radiators, delivering heat to the radiators while the boiler is heating. Gravity pressure is measured in Pascals or meters of water or Bars.

I would also like to add that the mass flow rate (measured in kg/sec) remains unchanged throughout the circulation ring. Those. if the entire circulation ring were made with the same diameter, then the speed along the entire length of the circulation ring would remain the same (in the section of the pipeline with a smaller diameter, the speed is higher, and in the section with a larger diameter, lower).

The main thing is that the system is designed so that bubbles can themselves be removed from those “pockets” (in which they can accumulate) using auto-air vents or through the main transit riser up into the expansion tank. In the same air “pockets” where bubbles do not accumulate constantly, you can limit yourself to installing Mayevsky taps.

Third misconception. In systems with natural circulation, the cooled one cannot move upward, and the heated one cannot move downward.

For a circulation system, circulation throughout the entire circulation ring is important. Some sections of the pipelines that make up the circulation ring “accelerate”, and some slow down. Let me remind you that the circulation is “accelerated” by the vertical sections where it goes down, and the circulation is “slowed down” by where it goes up. But, if, against the background of the total pressure in the circulation ring of about 300 Pascal, any section is “braked” by a pressure of about 20 Pascal, then the resulting pressure (inducing circulation) will still be 280 Pascal.

Those. It is possible, in a gravitational system, to bypass doorways (and so on) both below and above. But, of course, it would be necessary to hydraulically calculate (what the pressure drop will be in this section in Pascals) whether “braking” will be critical in each specific case. Let me also remind you that when highways bypass a doorway from above, it is very advisable to thermally insulate the rising section of the highway in order to reduce the “braking” effect. And in the upper part of the doorway contour, install an auto-air vent or a Mayevsky tap so that air can be removed from the upper “pocket”.

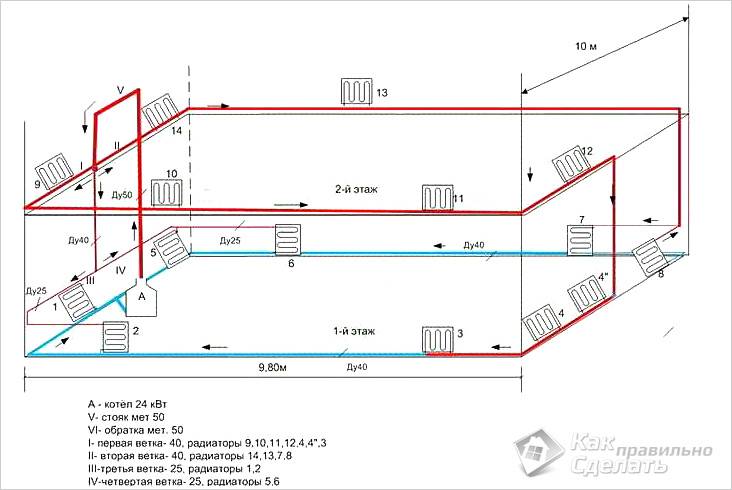

I will give an example of a diagram that, after performing a hydraulic calculation, will be operational with gravitational circulation. Although, of course, it is not optimal. In such a scheme, it is also desirable to thermally insulate the rising risers to reduce “braking”.

The fourth misconception. In gravity systems, the supply line (spill) must pass over all tiers of radiators.

Yes, placing the top outlet above all radiators would be optimal for many reasons (raising the cooling center and removing air through an open tank at the top of the transit riser). But this is not a necessary condition for the functioning of gravitational circulation. Let's look at an example of such a scheme in Figure 5.

Air in such a scheme can be removed using auto-air vents (highlighted in circles in the diagram). Well, the location of the cooling center and the required pressure need to be calculated.

Fifth misconception. With gravitational circulation, the centers of the lower level radiators should be located above the heating center (boiler heat exchanger).

For one-story house(especially with the “Leningrad” heating system scheme) this is indeed almost always the case. But in a two or more storey building, radiators on the first floor (ground floor) can be placed below the heating center. But, of course, the performance must be checked by hydraulic calculations.

![]()

Eighth misconception. The circulation pump must not be installed on the main transit riser between the expansion tank and the expansion tank.

It makes sense to install a circulation pump. The pump can increase the efficiency of the boiler, as well as increase the heat transfer of radiators. But you need to install the pump on the bypass of the transit riser. Also, the pump should be of low power, for example, Wilo Star 25/20, which has a pressure of about 2 meters of water column. Example correct installation pump on the bypass, shown in the photo below.

Moreover, it is impossible to install either shut-off valves or a spring check valve on the transit riser (its hydraulic resistance is too high for a gravitational system). To automatically switch from gravity circulation mode to forced circulation and back, you need to install a check ball float valve. Such a valve has very low hydraulic resistance when open and does not inhibit gravitational circulation. The operating principle of such a valve is shown in the figure below.

There are other misconceptions about gravity circulation systems:

· The expansion tank can only be installed above the main transit riser.

Let me explain that this rather concerns gravitational circulation with and without solid fuel.

· RB-expanzomat cannot be installed in the systems.

Let me explain. The same thing, you can’t install a TT boiler without it. Or with an old-style gas type AOGV with poorly functioning automation. This is also due to the fact that the permissible operating pressure of the boiler can be 1.5 Bar, and in an incorrectly designed closed system heating pressure can rise significantly higher. Which can lead to a boiler explosion.

· It is impossible to regulate the heat transfer of radiators using radiator thermal valves with thermal heads.

I'll explain. This is due to the fact that with poorly functioning automation gas boiler or in a system with solid fuel without, when the radiator thermal valves (thermal valves) are closed, the boiler may boil and explode (if the system is closed).

Reprinting is not prohibited,

with attribution and a link to this site.

Despite technological progress and constantly introduced innovations, the heating scheme for a private house with natural circulation has not outlived its usefulness. The secret to the longevity of this type of water heating circuit is its ease of installation and independence from other energy sources (electricity). The article is about how heating works with the gravity movement of liquid, and what types of circuits it includes.

What sets a liquid in motion - a little about the laws of physics

The basis for the independent movement of liquid along the heating circuit without the use of pumping devices (circulation pumps) is convection. This physical phenomenon is based on the fact that any medium, when heated, loses density, that is, it becomes lighter. This is also relevant for liquids, so more cold water in a closed loop it tends downward, pushing the hotter one up. The coolant heated in the boiler heat exchanger rushes up the vertical riser, and its place is taken by the cooled liquid coming through the return pipe.

This creates excess pressure sufficient to overcome gravity and pipe resistance. As a result, the coolant circulates independently, using only thermal energy, released by the energy carrier used to operate the boiler. The circulation of water in a heating system of this type is not very fast, so heating of the heated room when the boiler is initially started is slow. The following features of a gravity heating system allow you to increase the speed of water movement, which are taken into account when designing the circuit:

- the use of large diameter pipes (usually 50 mm or two inches) in order to minimize pipeline resistance;

- the boiler is mounted as low as possible relative to the horizontal wiring of the first floor;

- make an accelerating loop (a high vertical riser, from which a pipe leading to the batteries extends at the top point);

- horizontal sections of the wiring are installed at a slope (3-4 degrees) towards the boiler, using the force of gravity to accelerate circulation.

In addition, for normal speed of coolant movement through the pipes, the temperature difference between the outlet from the boiler and the inlet of the return pipeline must be maintained at least 25 degrees. The longer the circuit (the greater the number of battery sections), the higher the temperature difference should be.

A heating system with natural circulation has one more feature - it cannot be a closed type. In a gravity circuit, only an open expansion tank is assumed, which is installed above the top point of the accelerating riser. The compensation tank has two functions - to remove bubbles of formed gases from the system and to smooth out pressure drops, which can be significant in a gravity heating circuit. A closed membrane-type tank, which is installed in systems installed according to modern forced circulation schemes, will not be able to fully smooth out pressure surges, which will inevitably lead to emergency situations.

It must be taken into account that heating with natural circulation, due to the large diameter of the pipes, requires a much larger volume of coolant, which, expanding when heated, forms a significant amount of “excess” liquid, which fills the open compensation tank.

Heating with gravity circulation - assessing the advantages and disadvantages

In fact, the gravity system is less advanced than modern circuits, where the movement of fluid is provided by a circulation pump. But the heating systems under consideration have an undeniable advantage - natural circulation does not require electricity, from which the pump operates. No matter how long the power outages are, this will not affect the heating of the premises.

The advantages of gravity heating circuits include their inertia. This is relevant if you are using a classic solid fuel boiler, which is characterized by such an operational feature as large and frequent temperature changes in the firebox. The greater inertia of the circuit with the natural movement of the fluid smoothes out temperature surges in such a situation, making the heating of the rooms more uniform.

This is where the advantages of gravity heating systems end and their disadvantages begin, of which there are many more.

- 1. The use of large cross-section pipes and their mandatory installation at a slope do not make it possible to install hidden heating communications, so all elements of the system will be visible. In practice, only metal pipes(plastic ones don’t hold up well high temperature and pressure, involve many sharp transitions that increase the resistance of the pipeline). And this is the complexity of installation ( welding work) and the need for annual painting of communications. In addition, bulky pipelines laid in plain sight do not fit well with modern interiors.

- 2. Limited selection of heating batteries. For natural circulation, the diameter of the internal openings of radiators and their ability to withstand pressure and high temperature are very important. These requirements are best met by cast iron products, which are most often equipped with gravity circuits. Aluminum batteries are “weak” in terms of pressure and quickly oxidize (the rate of corrosion directly depends on the temperature of the coolant), bimetallic batteries have narrow openings, steel batteries are made in the form of monoblocks (non-separable design), so it is difficult to select the required thermal power of the radiator.

- 3. The need to deepen the boiler as much as possible. To do this, you have to make a platform located below the general floor level up to half a meter. As a result, the boiler is inconvenient to maintain (especially solid fuel) and to connect pipes to it when piping the heat generator. It is clear that we are not talking about the operation of modern wall-mounted boilers.

- 4. The area of heated premises is limited. Considering that the pipes are located at a slope, it will not be possible to lay them to a greater length. In addition, the longer the circuit, the greater its resistance, therefore, the lower the circulation speed. If the communications are long, the extreme points (batteries) will heat up poorly, and it will not be possible to achieve high-quality heating even by adding sections.

The heating system with natural circulation is not perfect, including aesthetically. However, the opportunity to not depend on electricity still attracts some homeowners, especially in regions where electricity problems often occur. For those who prefer reliability to technical perfection, several schemes for constructing a gravity circuit are offered.

Basic piping diagrams - choosing the best option

Heating circuits that involve natural circulation of coolant have two main design options (schemes):

- single-pipe, when the supply and removal of liquid from the batteries occurs through one pipe;

- two-pipe - the supply of coolant and its removal from the radiators is carried out by various pipelines.

The single-pipe circuit is easy to install. A riser extends from the boiler, which is raised as high as possible within the premises. An accelerating pipe extends from the top point of the riser and descends almost to the floor level, smoothly turning into the supply pipeline. Batteries are alternately connected to the communication along its course using two pipes of smaller diameter (with a two-inch pipeline, ¾-inch bends are usually used). Having “served” all the radiators, the pipeline turns into a “return”, which goes to the boiler. wiring is good only because of the simplicity of the device and relative aesthetics (the pipes are visible, but located low). Then there are only shortcomings.

Due to the fact that the cooled coolant from the batteries flows into the same pipe from which the hot liquid comes, the temperature of the water drops quite quickly after passing through each radiator. If the communication system delivers coolant at a temperature of 85 degrees to the first battery (for example), then the heater furthest from the boiler can only be counted on 60 degrees. This results in uneven heating, which has to be compensated by adding sections to the batteries moving away from the boiler, so the outer radiators are often bulky and heavy (especially if they are cast iron).

With single-pipe wiring, you can connect batteries only from below (input and output), and this is the most ineffective way to connect radiators (they heat up unevenly, which affects the quality of heating). Diagonal connection of radiators is possible if the supply pipe is laid above the batteries, but this is already a two-pipe scheme.

With a two-pipe distribution, a supply pipe located under the ceiling departs from the riser. From it, pipes descend to each battery (connected in the upper position). At the bottom there is a second, return pipe, into which the outlet pipes from the radiators flow (they are connected to the lower position diagonally). From an aesthetic point of view, the picture is not very good, but in terms of efficiency, this system is much better. Each radiator is supplied with a liquid of the same temperature, which ensures uniform heating of all rooms, plus it is possible to connect more heaters.

Planning and installation of heating with natural circulation is considered the simplest and most inexpensive way to heat a house. However, for the practical implementation of such a project, you should know all the nuances and rules for choosing components. Therefore, the heating system of a private house with natural circulation must be correctly calculated and its installation diagram worked out.

The principle of operation of heating with natural circulation

For any water heating system to operate, it is necessary to ensure the circulation of coolant through the pipes. When heated in the boiler, hot water must flow into radiators and radiators to transfer heat to the premises of the house. Water system heating with natural circulation is no exception.

The movement of the coolant occurs due to the difference in density in the normal and heated states. When a working boiler enters the heat exchanger, the water temperature increases and, as a result, the density decreases. Since the specific gravity of the cold coolant is higher, it begins to displace the heated one. As a result, mass movement is formed.

Before making water heating with natural circulation with your own hands, you should carefully read technical characteristics and specifics of operation:

- High degree of reliability. The absence of moving elements (circulation pump impeller) and pressure equal to atmospheric ensure long-term operation natural heating system of a private house;

- System inertia. Natural circulation in a closed heating system is ensured by a small pressure difference. Therefore, the rate of hot water flow to the radiators will be minimal;

- Mandatory compliance with the slope of highways. For normal operation, the slope of the heating system with natural circulation must correspond to the calculated data. The pipes are installed with a slope away from the boiler, and for the return line - towards the boiler. This ensures optimal system operation.

It should also be noted that installation of a heating system with natural circulation is recommended for schemes with a pipeline length of no more than 30 m. Otherwise, a large volume of cooled coolant will significantly reduce its speed.

The traditional scheme may involve the installation of a gas, solid fuel or electric boiler. It is important that their design includes a protection system against overheating in the event of reverse movement of the coolant or air locks.

Heating schemes with natural circulation

First of all, it is necessary to choose the correct layout of pipelines, radiators and boiler. Since heating with natural circulation can be done correctly only according to a pre-drawn plan, maximum attention should be paid to this stage of the work.

At the first stage, a primary analysis of the room (house) where it is planned to install a heat supply system is carried out. The living area, the degree of thermal insulation of the external walls and the type of boiler for heating water are taken into account. Currently, there are many schemes with which you can make heating with natural circulation with your own hands. The most popular are:

- Single-pipe. The best option for small houses and apartments;

- Two-pipe. Selected to provide air heating in houses with medium and large areas, two-story buildings.

However, given the principle of operation of a heating system with natural circulation, one should remember the main limitations - the total length of the pipeline, the minimum number of rotary units. Therefore, this scheme cannot be used for manifold or tee pipe routing. Too large hydraulic losses will negatively affect the speed of movement of the coolant.

When calculating a heating system with natural circulation, it should be taken into account that only water can be used in this system. Antifreeze is too dense to provide adequate pressure in the pipelines.

Single pipe system

For small country houses and country houses When calculating a heating system with natural circulation, not only technical (operational) characteristics are taken into account, but also the total cost of the project. The result should be a reliable and inexpensive heat supply system. Therefore, most often these houses have a single-pipe heating system with natural circulation.

A feature of this system is the presence of one highway. Radiators and batteries are connected to it in parallel, forming a single circuit. The main advantages of a single-pipe heating system with natural circulation are the minimum number of components, low material consumption and ease of installation. However, it must be taken into account that the cooling rate of the coolant in this system is quite high due to the sequential transfer of heat to each radiator in the circuit.

For optimization thermal regime In the natural heating system of a private house, it is necessary to provide for the presence of the following components:

- Bypass in the piping of each radiator. It will make it possible to limit the flow of coolant into the battery without changing the parameters of the entire system. With its help, you can completely turn off the heating device for replacement or repair without stopping the heat supply;

- Battery-powered thermostats. They are installed in a heating system with natural circulation paired with a bypass. An automatic thermal element will change the cross-section of the flow diameter of the radiator pipe, thereby regulating the degree of heating of the device;

- Mayevsky crane. An essential component in the radiator piping. Since it is not always possible to accurately calculate a heating system with natural circulation, you should consider a system for removing air. This is exactly what the Mayevsky crane is designed for.

Another advantage of a single-pipe natural circulation heating system is its small footprint. The installation of the main line can be done either open or in a closed way. It is only important to ensure that radiators are connected to it.

For a water heating system with natural circulation with one pipeline, the boiler and radiators can be located on the same level, which is prohibited for other schemes.

Two-pipe system

Stable heating operation in medium and large houses can only be ensured by separating hot and cold water flows. In this case the best option There will be a two-pipe heating system with natural circulation.

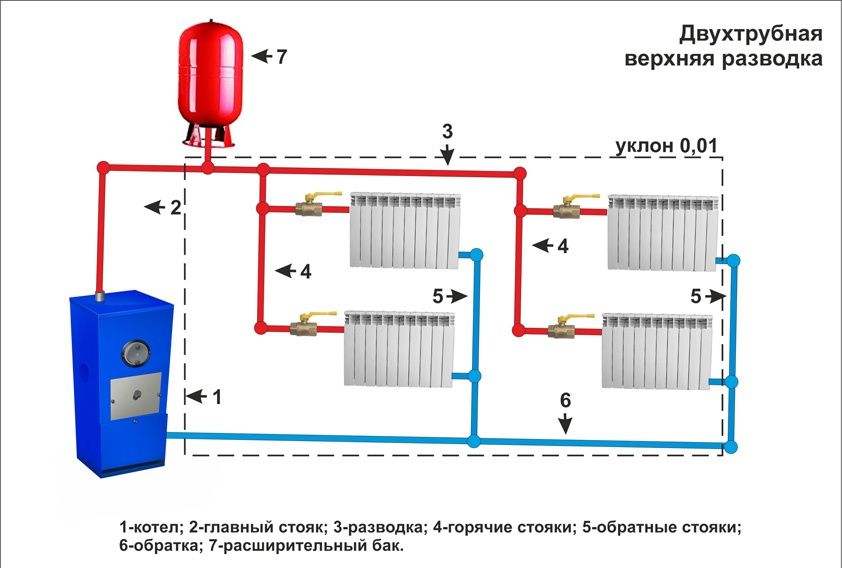

For normal operation of the system, it is necessary to install the boiler below the level of the radiators. This is necessary to create pressure of cooled water, which creates natural circulation in a closed heating system. For better pressure, it is necessary to make an accelerating riser immediately after the boiler. An expansion tank is installed at its highest point. A spill pipe is mounted from it at an angle, to which radiators are connected.

A correctly calculated and installed two-pipe heating system with natural circulation will work even with a minimal temperature difference between the cooled and heated coolant. To implement such a project, the following nuances must be taken into account:

- Boiler location Do-it-yourself water heating with natural circulation. Most often it is located in the basement or basement. It is necessary to ensure normal temperature regime, ventilation and natural lighting;

- Control pipe on the expansion tank. Even if you correctly calculate a heating system with natural circulation, there will still be a possibility of a critical decrease in the volume of water. Using the control pipe, you can monitor this indicator;

- Water replenishment and drainage units. They are located at the lowest point - on the return pipe. In order to properly make heating with natural circulation, you should provide in advance for methods of automatic (semi-automatic) replenishment of the system, as well as prompt drainage of water.

Thanks to the emergence of new materials, you can make a two-pipe heating system with natural circulation with your own hands from steel or polymer pipes. It all depends on the budget, availability of appropriate tools and materials.

In a two-pipe heating system with natural circulation, the installation of bypasses is not necessary. It is only important to provide for the installation of shut-off valves for possible disconnection of the device from the public main.

Calculation of heating power with natural circulation

To calculate the basic parameters of heat supply, it is recommended to use specialized programs. With their help, you can calculate a heating system with natural circulation as accurately as possible. But if this is not possible, other, simplified methods are used.

The easiest way is to calculate the required boiler power using the ratio of 1 kW of thermal energy per 10 m² of area. In this case, the obtained result must be multiplied by a coefficient that depends on the climatic conditions of the region.

Its values for a water heating system with natural circulation are given in the table. These coefficients are recommended and may be replaced by others depending on the actual characteristics of the house. But in any case, this method will allow you to determine the approximate parameters of the heating system. Therefore, its use is a mandatory step in the design of heat supply.

However, this does not take into account the degree of thermal insulation of the building, the number and characteristics of window and door designs. Therefore, it is best to use another method for calculating a heat supply system with natural circulation. Calculation stages:

- 1 m³ of residential building will require 400 W of heat. By multiplying the power by the volume of the building, we obtain the initial value of thermal energy.

- To compensate for heat losses through windows, we multiply the number of structures by 100 W. The same technique is used for external doors, but with compensation of 200 W per each.

- If the room has external wall, then for normal operation natural system heating supply of a private home, the result is multiplied by a correction factor of 1.2.

- For private houses, heat losses through the roof and floor are taken into account using a coefficient of 1.5.

It should be noted that even this calculation will be approximate. When planning the installation of heating with natural circulation with your own hands for a large house, it is recommended to contact specialists to accurately calculate the main characteristics of the system.

To minimize heat losses in a building, good thermal insulation of external walls, ceilings, and roofs is necessary. This will reduce running costs for water heating with natural circulation, made by yourself.

Rules for drawing up a heating scheme with natural circulation

Knowing the basic principles of operation of a heat supply system with natural circulation and choosing the optimal scheme, you can begin to assemble it. This stage is no less important than the previous ones, since the technical parameters of the components will depend further work heating.

It is necessary to take into account all the features of this system. In schemes with forced circulation, compensation of hydraulic losses occurs due to the operation of the circulation pump. For systems with natural circulation in closed heating no such mechanism exists. Therefore, to minimize losses, you should pay attention to the following points in the design and selection of components:

- Heating pipes. Their diameter should be from DN32 to DN40. This compensates for the friction of water on the inner surface. It is also recommended to choose polymer products with a smooth wall. Their actual outer diameter is from 40 to 50 mm;

- Highway layout diagram. It is necessary to avoid rotary units that increase hydraulic resistance in the system;

- Acceleration riser height. In the heating circuit two-story house with natural circulation it should be higher than the ceiling of the second floor. The expansion tank is located in the attic;

- Characteristics of shut-off valves. Its presence should not affect the system parameters.

To better understand the operating principles of the heating circuit of a two-story house with natural circulation, an analogy can be drawn with well-known communicating vessels. In this case, the boiler will be located below the level of the radiators, therefore the flow of liquid will circulate towards it. That is why when developing a diagram and installing a heating system with natural circulation, it must be located as low as possible.