The main task of room ventilation is to remove smoke, unpleasant odors, steam outside and replace the air. Previously used everywhere natural circulation air, but modern renovations apartments do not allow this option to function effectively. A kitchen exhaust fan with a check valve solves this problem. Without forced aeration, mold will begin to appear in the corners, and the walls will constantly be covered in soot from cooking.

Operating principle of a check valve

There are exhaust, duct and supply fans, the design of which includes a check valve. They are used to gradually replace air. The advantage of a valved exhaust fan over an air conditioner is that the former creates a flow fresh air, and does not work with what is already available.

Such hoods are often used not only by residents apartment buildings, but also private. They are used for:

- kitchens;

- laundries;

- bathrooms and toilets;

- sanitary compartments;

- office smoking rooms, etc.

The hood has quite simple design. Check valves are divided into three types:

- Spring-loaded. It is also called self-closing.

- Operated (manually or electrically).

- Passive. Closing or opening of the lid occurs under the influence of air flow.

The spring type is usually installed in the kitchen or bathroom. The cover is always open while the engine is running. When the fan turns off, the check valve cover closes under the action of a spring. It does not provide complete sealing, but protects well from foreign odors.

The spring type is usually installed in the kitchen or bathroom. The cover is always open while the engine is running. When the fan turns off, the check valve cover closes under the action of a spring. It does not provide complete sealing, but protects well from foreign odors.

Hoods with controlled electric valves are provided when it is necessary to create automated system ventilation. They are used in industrial premises: warehouses, in some workshops, factories, as well as in sales areas and large offices. Such ventilation prevents the formation of fungus, mold and condensation.

Passive ventilation is the least common. Sometimes it can be used for a regular kitchen hood.

Check valves can be made with or without heating. This feature prevents ice from forming in winter time. This is necessary if the device goes outside. An unheated hood is used indoors only.

Fan selection

Hoods for cellars, bathrooms and kitchens are produced in different modifications and sizes, as well as with different blade shapes. Some models have an inertial grille. It works on the principle of blinds. After the engine has finished running, the grille closes. There are also economical models, in which a timer is built in. With its help, you can set the periods of operation of the device.

Hoods for cellars, bathrooms and kitchens are produced in different modifications and sizes, as well as with different blade shapes. Some models have an inertial grille. It works on the principle of blinds. After the engine has finished running, the grille closes. There are also economical models, in which a timer is built in. With its help, you can set the periods of operation of the device.

When purchasing a device, you should consider the presence of a power regulator, as well as manual fan shutdown. For a room with high humidity(bath, shower, steam room, etc.) it is worth choosing models that provide an appropriate controller. It is also important to consider some factors when choosing:

- The volume of the room in which ventilation will be installed.

- Object type.

- Number of residents.

Sufficient power of the device will ensure good ventilation and prevent mold and mildew from forming. This can significantly improve your quality of life.

Kitchen hood

Food preparation takes place every day in the kitchen. During this large number grease, smoke and steam settle on the walls, curtains and rise to the ceiling. Natural ventilation has often been faulty for a long time. To avoid soot settling on surfaces, you need to install an exhaust fan with a check valve.

Food preparation takes place every day in the kitchen. During this large number grease, smoke and steam settle on the walls, curtains and rise to the ceiling. Natural ventilation has often been faulty for a long time. To avoid soot settling on surfaces, you need to install an exhaust fan with a check valve.

The most simple option installation is installation above the stove, and the output can be made directly into the ventilation shaft. If the apartment has old windows, then you can install a fan in the window. For a private house, it is necessary to make a hole in the wall to remove stale air.

Productivity (volume of pumped air per hour) is a very important parameter. For the right choice For hoods, you need to know the volume of the kitchen: multiply the height by the length and width. Sanitary standards stipulate that a certain number of complete air replacement cycles must occur in the room. For the kitchen, an indicator from 8 to 12 is applied. There is also a safety factor, that is, losses that may occur due to a ventilation malfunction. Typically a value of 1.3 is used. To calculate the required productivity, multiply the volume, the multiplicity and this coefficient.

The second point that you should pay attention to when buying a hood is the noise level. It is created by a motor that rotates the fan blades.

Don't forget about power. The higher it is, the better the exhaust air leaves the room. The check valve will prevent it from returning to the kitchen. But a powerful hood costs much more than a mid-range fan.

Often the ventilation system does not work efficiently and some of the air penetrates from the ventilation duct back into the apartment. The effect of reverse draft ventilation is especially noticeable in kitchens or bathrooms of apartments. Check valves will help combat unpleasant odors.

Operating principle of a ventilation check valve

Non-return valves in ventilation are a group of protective devices used to prevent rotation of the air flow in exhaust ventilation systems or simply reverse draft ventilation in apartments. The valve allows air to flow in the desired direction, inhibiting reverse movement. Check valves for exhaust ventilation work automatically and this is the main advantage of their use. In ventilation systems of residential and public buildings check valves are used to prevent air from entering the common ventilation duct into separate rooms.

Check valves for exhaust ventilation operate in systems with natural and mechanical draft. The valve protects against the penetration of insects and dust into household ventilation.

If the system is not equipped with a check valve, drafts may occur.

Types of ventilation check valves

Main structural part any check valve for natural ventilation- this is a shutter. It is he who does not allow air to pass in an undesirable direction.

There are two types of round and rectangular check valves for ventilation:

- with a spool-shaped shutter;

- with a disc- or flap-shaped shutter.

The first ones are used for working with liquid media. The second ones are created specifically for ventilation. They come with a horizontal or vertical axis of rotation, as well as single-leaf and double-leaf.

Check valves for ventilation are produced in rectangular and round shapes, with different diameters sections.

The main parameter when choosing a check valve is its throughput.

Check valves for natural ventilation are easy to manufacture and very reliable.

They are made of plastic or metal, the material is selected depending on the characteristics of the system. In vertical pipelines, the air flow moves vertically, so the valve is mounted horizontally, which ensures correct work shutter

The most commonly used are round and rectangular check ventilation valves with a capacity of 4 to 6 m/sec. They work silently and efficiently. They are installed either independently or in conjunction with an exhaust device.

All check valves for rectangular or round ventilation are also divided into:

- Heated. Such check valves for ventilation with an electric drive have the advantage: condensation does not collect in the system, and the structure will not become covered with ice in severe frosts;

- No heating. Good for indoor use only.

The presence of an electric drive at the check valve for ventilation requires the participation of an electrician in connecting it.

Although the device is cheap, you can assemble a check valve for ventilation yourself, but more on that later.

Check valve design for ventilation

The design of a check valve is very simple: a flap disk is attached to an axis, allowing it to swing freely. To cover the valve when the fan stops, a plumb line is attached. Ventilation valves can be rectangular, round or square.

Industrial models differ from check valves for domestic ventilation in diameter and material; they belong to the explosion-proof category, although the device is the same.

Diameter of round or rectangular check valve for ventilation industrial type can be from 125 to 1000 mm, they are installed in explosive industries.

The butterfly valve model with two blades is widely used.

Butterfly devices are often made of metal; the axis for attaching the blades is installed in the middle of the section. As soon as the fan stops, the blades cover the cross section and the reverse draft of ventilation in the apartment stops. The diameters of butterfly valves vary from 100 to 315 mm.

The improved modification of the “butterfly” is equipped with seals that reduce noise when the blades operate.

A check valve in the form of blinds or petals (inertial grille) is very often used for ventilation in the kitchen. There are several blades in the design; they are located on horizontal axes.

How to choose a check valve

When purchasing a check valve for kitchen ventilation or a bathroom, you need to take into account the speed of air movement, because the valve must respond to even the slightest flow. Poor draft in the system is main problem when organizing a natural ventilation system. Therefore, most owners combine the valve with exhaust fan. To cover the structure from the side of the room, a beautiful ventilation grille is installed.

But in order for the natural ventilation system to work flawlessly, it is important to choose the check valve correctly. Otherwise, reverse draft in ventilation apartment building will continue to poison the existence of residents.

You should pay attention to:

- section shape;

- section diameter;

- valve material;

- valve device;

- valve purpose;

- manufacturer (affects more the price than the quality of the simplest mechanism).

Can be purchased now ready set from a fan and a check valve. Here you need to pay attention to the fan power. For the kitchen it will be suitable with a factor of 10, and for the bathroom and toilet 7 will be enough.

When purchasing a check valve for domestic ventilation of a private home, it is important to take into account the climatic conditions. For example, a “butterfly” will become covered with ice faster than a single-axle structure. In private houses, unlike apartment buildings, residents are annoyed not by the reverse draft in the apartment, but by the wind blowing into the ventilation and rodents entering it.

Do-it-yourself check valve for ventilation

Do-it-yourself installation of a ventilation check valve is especially relevant for residents of the top floors of houses, where the problem of “foreign” odors being drawn in through the air ducts of the general exchange system is common.

We offer an improved model of a ventilation check valve with an electric drive and a fan.

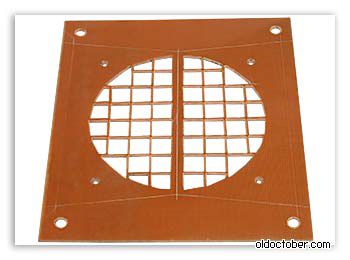

Thick plastic or textolite is suitable for the base of the kitchen ventilation check valve. You will need a plate the size of which covers the exit of the exhaust duct and a thickness of no more than 4 mm. Markings are made on the plate: a grid the size of the fan hole, as well as holes for mounting to the wall (in the corners) and for mounting the fan.

The larger the grid cells, the denser the material for the sashes should be!

To prevent air from “walking” between the base and the fan, a rubber gasket is used.

To prevent not only reverse draft in the ventilation of an apartment in an apartment building, but also the penetration of insects, a fine plastic mesh or even nylon from tights is attached to the base grille. The latter is easily replaced. And so that residents are not disturbed by vibration from the fan motor, rubber shock absorbers are used during installation.

The doors are made of thick polyethylene (at least 0.1 mm). The film must be perfectly smooth; the slightest waviness will disrupt the tightness of the ventilation, and the reverse draft in the apartment of the apartment building will resume. The doors can be secured with tape with a fabric base. Detailed instructions on making flaps for a plastic ventilation check valve in the video:

We recommend cutting the doors in place, from an already glued piece of film. Moreover, if it is slightly wrinkled during operation, it needs to be changed. The two sashes are cut together only at the very end of the process. You need to cut with a sharp construction blade.

To ensure that there is no gap between the homemade plastic check valve for ventilation and the wall, use self-adhesive foam tape.

During operation, it is necessary to periodically clean or replace the plastic mesh that becomes clogged with dust.

At correct production such a homemade plastic check valve for ventilation will last for many years. And apartment residents will get rid of the reverse draft typical for ventilation of apartment buildings for a long time.

Serves to remove various odors. But sometimes it happens that it is through it that tobacco smoke from neighbors or something similar enters the home. Moreover, in case of drafts or strong wind Instead of an exhaust hood, ventilation can work as an inlet. So how can you get rid of such problems? The solution could be a ventilation check valve, which will prevent various odors from entering the house. Now let's try to understand what it is, how it works and how difficult it is to install it in your home.

Read in the article:

Check valve for ventilation - what is it for and how it works

The essence of such a device is this: when in the open position, the valve freely allows air from the room to the outside. But at the same time, as soon as the flow rushes in the opposite direction, the device is triggered, blocking the path inward. The essence of his work is quite simple. The petal is located inside in such a way that the flow can pass in one of the directions. In case of return, the air itself closes its path by turning this petal across the pipe.

An additional advantage of such devices is the ability to regulate the speed of the air flow that passes through it. But the main purpose for which a check valve is needed for ventilation is, of course, to prevent flows of cold air through the shafts into the apartment. Although many underestimate its necessity. You can give an example. IN next apartment a gas leak occurs. And at the same time, the air from them comes back to you. And despite the fact that gas is mostly natural everywhere now, and not liquefied, it has no smell. There is hardly a person who wants to get into such a situation.

And now, having understood the function of such a device, what it is needed for and how it works, it makes sense to move on to the types and types that the manufacturer presents on store shelves.

What types of check valves for ventilation are there?

Such devices can be with a vertical damper or a horizontal one. Selecting a suitable air valve for ventilation should be based on the direction of flow in the shaft. At wrong choice it may simply not work when it is needed. The materials from which the petals are made also differ. Check ventilation valves whose damper is made of metal are considered more durable.

Expert opinion

Ask a specialist“It’s almost impossible to find a normal air exchange system these days. The haste of builders, little knowledge of such systems - all this affects the quality. That is why, most often, installing ventilation check valves is the only option.”

It is for this reason that such devices have received such widespread. Although, as absurd as it sounds, with all their popularity, many do not even know what they are and what they are needed for. But sometimes there is no other option but to install such a valve for ventilation. For example, if you take apartments on the first floors of old houses, where dampness emanates from the basements and therefore the walls are periodically covered with fungus. Or upper floors with roof leaks. It is in such cases that forced ventilation with the impossibility of inflow can help. Of course, this will not stop the roof from leaking, but the humidity in the room will decrease significantly.

Well, now it’s worth considering the types of such devices presented on the shelves of Russian stores.

Existing types of valves for ventilation and their features

There are three types of such devices:

- membrane;

- petal;

- butterflies.

Let’s look at them in a little more detail now.

Diaphragm type check valve

This type is most often used in apartments with natural ventilation. The fact is that the membrane in it is quite flexible and even a small natural flow is capable of bending the petals and penetrating through it. In the opposite direction, the membrane does not allow air to pass through, thus ensuring the operation of the check membrane valve.

Leaf check valve and its features

This design resembles blinds in appearance, the plates of which open under natural air flow or with the help of. It is also a fairly common type that is used in apartments. Leaf-type check valves for ventilation have gained popularity due to their compact size (they can be installed instead of a ventilation grille).

Butterfly valve, its structure and principle of operation

The least common type, the principle of operation of which differs little from the membrane one with the only difference being that two semicircular or semicircular petals act as a barrier in the butterfly check valve. rectangular shape, fixed by a common axis in the middle. Under the influence of air flow in the right direction, they open. They are mainly used in forced ventilation, although, like other types, they can be used in natural ventilation, although less frequently. The fact is that the metal petals do not compress with a weak flow, which means there is no talk of any passage of air.

Related article:

In the article we will consider in detail the types of structures, the principle of operation, how to choose a place for installation, how to properly install the device with your own hands, useful tips and recommendations from experts.

Also, all three types of check valves can be automatic, mechanical or electronically controlled. Such devices will be controlled either using a microcontroller and temperature and humidity sensors, or via a remote control remote control at the necessary moments.

Possibility of using check valves in kitchen ventilation

Probably the most widely used similar devices in kitchens Russian apartments. It is very convenient when the valve is installed, for example, on a built-in hood. After all, if during operation such a device draws in smoke from hob using a fan, then when turned off, odors may well enter through it, forcibly expelled by the hood operating at the neighbors. And this, you see, is not very pleasant. It is in this case that a non-return valve in a kitchen hood will come in handy.

It is important that even with such an air exchange device it is necessary to think about duplication. After all, in addition to the hood above the stove, there is one more hole for ventilation in the kitchen, a check valve in which will also not be superfluous. With this arrangement, the most appropriate would be to install a butterfly in the hood and a membrane or petal type on natural ventilation.

Is it necessary to install a check valve in the bathroom?

There shouldn’t be any disagreement here either – it’s definitely needed. It’s not very pleasant when, while under the shower, you suddenly feel a breath of cold air. And there is enough moisture in such rooms to allow additional dampness to penetrate from neighbors. And although check valves are not a panacea for ventilation in the bathroom, they still retain the main air coming from outside.

For your information! To better ensure the capabilities of such devices, it is recommended to use forced ventilation, i.e. using fans.

Forced ventilation device and its pros and cons

It is quite convenient when, if there is any smell in the kitchen or dampness in the bathroom, you can turn on the fan, which will quickly remove unwanted air from the room. Often such devices are installed on windows or vents. And yet, in addition to positive qualities, they also have negative qualities, such as the need to supply electricity to them.

And yet there are cases in which forced ventilation cannot be avoided, and these have already been mentioned earlier. However, the most interesting thing is that devices requiring connection can be both stationary and mobile. And if you choose a fan with a built-in check valve directly to the size of the window, then you can install it only at the necessary moments. The rest of the time he will clean up. Such devices do not require a dedicated connection, because For a while they can be powered through an extension cord.

Let's try to look at such devices to understand how they work.

How does the check valve interact with the fan?

When installing a fan on the window of a room, it becomes possible to ventilate it faster. When voltage is applied, the blades begin to rotate, drawing air out of the room and opening the valve petals. Well, when turned off, the valve closes, blocking the access of cold street air to the apartment. As you can understand, the essence of the device is elementary.

It is also possible to install a valve with a mechanical drive, when the owner himself, manually, can close or open it. In fact, it is precisely on this principle that the check valve on a hood with a fan works. The only difference is the location – horizontal or vertical.

Ventilation grille with check valve: how to install it

Such a device is very convenient not only to use, but also to install. The fact is that special skills for its installation, as well as specialized tool, will not be required. It is enough to dismantle the old grille and install a new one equipped with a check valve in its place.

Essentially working like blinds deployed in reverse side, the device and regulates air flows. With the help of such a ventilation grille equipped with a non-return valve, extraneous odors are cut off, as well as cold street air. As for purchasing such devices, there are no problems with it. And the cost ventilation grilles with a valve is quite acceptable these days.

Exhaust tees and methods of their use

It is no secret that when installing a built-in hood, you need a tee, which will allow you to both connect the equipment to the ventilation system and allow natural air exchange in the room. Nowadays, quite a lot of them are produced, with various modifications. It is the tees for hoods with check valves that are of interest, and their number may vary.

Usually two check valves are built in - for the exhaust and for natural ventilation, but sometimes a duplicate one is installed - on a common pipe. In general, tees with check valves for ventilation are not used so often. It is believed that one air damper at the input is quite enough. But here, of course, it depends on taste and color.

Installing a check valve on a kitchen hood

This is the most common arrangement of the air damper. Well, this is quite natural, because installing one check valve for an exhaust hood is much cheaper than purchasing a tee with two or three. Moreover, most often, in modern devices similar devices have already been installed for forced ventilation. And if a regular hood with an old-style check valve can still let a small amount of air back, then newer models are free of such a “sore”.

Expert opinion

HVAC design engineer (heating, ventilation and air conditioning) ASP North-West LLC

Ask a specialist“Some technical documentation states that an anti-return valve for the hood is built-in. What is this you need to remember. In essence, this is the same check valve, but it operates much faster and thereby prevents even the slightest ingress of external air. But what can be said absolutely for sure is that it only works with forced ventilation, or connects to the network and is controlled automatically.”

Video: installing a Domvent home ventilation valve

Making your own check valve

Even though the cost of such factory-made products is not too high, there will always be those who like to do everything with their own hands. Check valves for ventilation are also no exception. Let's try to figure out whether this is difficult and what you will need for such work.

It is done quite simply. For this you will need:

- ventilation grille;

- two soft plates (film from a fluorographic apparatus may well be suitable);

- hot glue gun.

On inner side The grilles are glued to the plates in such a way that they are fixed only on opposite sides. The middle parts should move freely and meet at the edges exactly in the middle. That's all the work - the simplest homemade check valve is ready. The grate is put in place, after which it does not allow air to pass out of the shaft. It passes freely from the room, bending the plates.

Well, for those who think that it is better to purchase such a factory-made product, we offer short review models and their costs.

Prices for various types of check valves for ventilation

The range of prices for such devices is decent, and therefore we will give examples from various categories.

| Model | Country of origin | Warranty period, months | Cost, rub. |

|---|---|---|---|

Shuft RSK 100 | Russia | 12 | 260 |

Shuft RSK 355 Shuft RSK 355 | Russia | 12 | 1800 |

ATS 190 ATS 190 | Russia | 12 | 1900 |

VENTS 2121 VENTS 2121 | Ukraine | No | 70 |

KON KON | Czech Republic | No | 850 |

As can be seen from the table, such devices are quite affordable. In addition, the ease of their installation makes them even more attractive to the consumer. If you look at the cost, you can even buy a plastic check valve for ventilation for 70 rubles, which is good news.

As for valves with additional equipment, the price categories are slightly different.

| Model | Power, W | Voltage, V | Cost, rub. |

|---|---|---|---|

SOLO 4C SOLO 4C | 20 | 220 | 3400 |

SILENT-100 SILENT-100 | 20 | 220 | 5400 |

SILENT-200 SILENT-200 | 25 | 220 | 8500 |

EDM 100C EDM 100C | 15 | 220 | 2500 |

STANDARD 5C STANDARD 5C | 16-20 | 220 | 1100 |

For approximately the same amount, you can buy a check valve for ventilation, which will provide forced air outflow.

Article

In case of ineffective work ventilation system may appear indoors bad smell. This is due to the fact that exhaust air, being drawn out of one room, returns to another, drawing along with it odors from the natural ventilation channel. This problem is especially noticeable in the bathroom and kitchen. To avoid this problem, it is recommended to install a check valve for ventilation.

Functions and design features

Despite the simplicity of the design, the exhaust valve performs useful function, preventing exhaust air from being drawn into the room. The reasons may be the following:

- Poor sealing of ventilation ducts.

- Ventilation duct clogged.

- Incorrect location of the hood.

- Increased combustion draft in a private house with stove heating.

- Air flow disruption due to the installation of a powerful hood in one of the apartments multi-storey building. This is also possible in cases where the air duct of an apartment building is designed without taking into account the possibility of installing devices for forced ventilation.

- Availability several hoods in the apartment, due to which an uneven pressure of air flow is created.

- Change external environment behind the walls of the house (change in relief when construction work, demolition of buildings, etc.).

Therefore, to ensure normal movement of exhaust air, a check valve is installed. The design of the reverse is simple: on a single axis there are blades that allow air to flow in only one direction. When the movement of air flows changes, the flap closes, preventing them from entering the room.

Device classification

Types of exhaust valves can be divided into several groups:

- By design.

- By type of control: manual and automatic.

- By type of installation: horizontal, vertical.

- Shape: round, rectangular. The choice of a round or rectangular valve depends on the shape and cross-sectional size of the air duct.

- By throughput. Depending on the volume of air that passes through the valve per unit of time.

- By material of manufacture: metal and plastic. More often, a plastic check valve is installed for ventilation, as it is less noisy.

The right choice

When choosing a device, it is necessary to take into account the speed of air flow inside the natural draft ventilation duct. It is important that the valve blades respond even to weak flows. Since low draft is common in natural ventilation, a fan with a check valve is often installed in it. At the same time, it is also important to have an idea of how to choose the right fan: its power is selected based on the area of the room. To calculate the air exchange efficiency of each room, different indicators are taken into account.

To select the right vent valve, you should pay attention to the ambient temperature. When installing on a duct leading through a wall to the street, it is recommended to use a “blind” type valve, since other types are not resistant to low temperatures. The price when choosing a device is not decisive, since it depends on factors such as the type of section, dimensions of the structure, material of manufacture, etc.

In addition, when choosing a suitable device, you should consider the way it is installed. Thus, a single-leaf check valve for gravity ventilation is installed strictly horizontally or vertically, while a butterfly valve can be installed at any angle.

Homemade check valve

Making a homemade exhaust valve is relevant in cases where the ventilation duct is of non-standard shape or size. Homemade design will cost less than adjusting the air duct box to standard sizes. If the house has natural ventilation, it is better to make a non-return valve of a membrane or single-leaf type from a rigid material. Before making a check valve, you should pay attention to the following nuances:

- The plate should fit snugly against the walls of the device body so that no gaps are formed that allow air to pass through.

- Plate knocking must be avoided, especially if the direction of air flow in the air duct often changes.

To make the blades, you can use Mylar film, the diameter of which should exceed the opening of the ventilation pipe. To prevent the film from deforming during reverse thrust, you can attach a grid on which it will rest. The simplest check valves are made of a grid to which a film is glued on both sides.

How to install the device correctly

Installation of a check valve for ventilation is carried out at the beginning or end of the air duct pipe. To do this, the round or square body of the device is inserted into the ventilation duct, the walls of which are marked with its location. After this, holes for fastening are drilled at the marked points. The check valve is fixed with dowels. There should be no large gaps between the body and the channel walls. The gaps should be filled with sealant.

Installing the valve on exhaust ventilation protects the premises of a house or apartment from the reverse penetration of polluted air. In order for the installation of the device to promote high-quality air outflow, the installation must be carried out in compliance with the basic rules: compliance of the membrane with the diameter of the ventilation duct opening, its tight fit to the grille, and carefully sealed gaps between the device body and the air duct box.

IN multi-storey buildings Sometimes there is a problem with the appearance of unpleasant odors from natural ventilation channels. They appear when the ventilation system does not operate properly, when the exhaust air is not exhausted outside, but is returned from one room to another. One way to solve the problem is a check valve for natural ventilation installed at the outlet of the ventilation duct. This situation occurs not only in houses and apartments, but also in all buildings with a gravity ventilation system.

Ventilation systems for all types of buildings are divided into two groups:

- with natural impulse (gravitational);

- with artificial motivation (mechanical).

They differ in the mechanism for driving air. Natural systems consist of structural elements:

- external windows, doors and other openings in building envelopes;

- ventilation shafts (channels).

To organize a mechanical system, fans, an air duct system and other components are used. It is more convenient to set up and allows you to control air exchange parameters, but is significantly more expensive than the natural one. Most apartments and residential buildings use gravity ventilation. Vertical ventilation shafts and tie-ins are installed for it on each floor of the outlet to the premises. What types of natural ventilation check valves are there and how are they used?

Operating principle and types of check valves

A check valve for mechanical systems and natural ventilation belongs to a group of air dampers and regulators designed to change and block the movement of air in the supply and exhaust systems. If the device accepts only the “open” or “closed” positions, then it is considered two-position. In multi-position products, the air damper assumes several positions (with different throughput) during operation. Check valves use air to move in one direction only and are two-position devices.

Structurally, check valves are produced in the following types:

- petal;

- with gravity grid.

Models with a gravity grille are installed at the end of a branch of the ventilation system. For example, at the exit from the exhaust network to the street. They are grilles in which the blinds rise freely from air pressure and fall under the influence of gravity. Such check valves are used only when air moves in horizontal position.

Such a product is not applicable in a natural ventilation system due to its operating characteristics. If you install it at the exit from the ventilation shaft, then the pressure of the air flow naturally rising through the channel rarely reaches such a value that can raise the blinds on the grille.

Valves of the second type consist of a body and petals that completely cover the channel cross-section when the air flow moves in a direction other than the designed one. They are conventionally divided into two groups - single-petal and two-petal (butterfly type).

In check valves of the first type, the petal, which blocks the movement of air, is loosely attached to an axis in the cross section of the product. The position of the petal depends on the valve angle and air pressure. When the system is turned off, they can be in both the open and closed positions, and when air moves in the desired direction, the flow area increases in proportion to the pressure.

Products with two petals are equipped with a spring retainer or counterweight. If there is no air movement, the device is completely closed. They are used in vertical and horizontal positions, in contrast to single-lobe ones, which, with the calculated air movement from top to bottom, cannot be installed in a closed position when the system is stopped. All types of valves are produced for both rectangular and channels round section. Maximum speed movement in the cross section of the check valve is 12 m/s.

Due to technical and design features two-leaf valves with a spring are not applicable in natural ventilation systems, since the pressure in them is not enough to open. Single-leaf devices work effectively as check valves in a natural ventilation system. Let's consider the application diagram.

Use in natural ventilation

A check valve for natural ventilation is used in a system using one connection channel mechanical device(for example, a kitchen hood) and grilles. When reverse draft occurs from the street in a natural system, the valves are not effective due to the low air speed. The same applies to the problem of unpleasant odors from neighbors' kitchens.

Mechanical fans and kitchen hoods cannot always be connected to common ventilation ducts. In some series of multi-storey buildings, outlets on several floors are connected to one shaft, and when a fan cuts into it, the pressure increases so that the air leaves the channel not only outside, but also into neighboring rooms. But if the air duct leads from the apartment to the outside without branches, then such designs are allowed.

Even if only one ventilation duct comes out of the kitchen, bathroom, or other room, it can be used for both natural and mechanical exhaust by installing a check valve. For example, the photo shows a diagram for a kitchen hood.

When using shut-off and control devices, do not forget that they become clogged with dirt, dust and grease deposits. Check valves require regular cleaning and inspection to function properly.