Having autonomous heating in your home is very convenient, since you can independently set start and end dates heating season, set any temperature mode.

The leaders in popularity among heating equipment are electric and gas boilers. This demand is explained by the fact that they have the highest level of automation and temperature programming.

In this article we will talk about the features of gas and electric boilers, leading manufacturers and how to choose the right boiler for your home.

A gas boiler is a unit that uses the heat of burned gas to heat the coolant, which heats the air in the room. The coolant can be water, antifreeze or air itself.

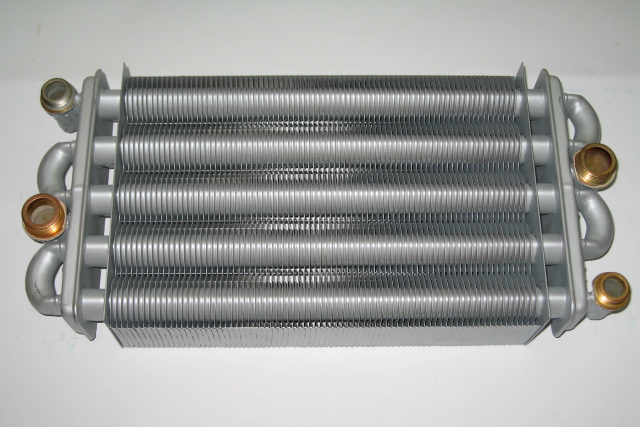

The transfer of heat from the flame to the coolant occurs in the heat exchanger. This is a metal tank (cast iron, steel or copper) connected to a heating system through which the coolant continuously circulates.

The heat exchanger of a gas boiler may consist of two non-communicating circuits. In the first circuit, the coolant is heated for heating, and in the second circuit, water is heated for household needs. Such boilers are called double-circuit boilers.

Gas burner

The fuel for a gas boiler is not just gas, but a gas-air mixture. The preparation of fuel before combustion occurs in the burner: it mixes gas with air and supplies the mixture to the combustion chamber in a certain amount.

Combustion chamber

The element of the boiler in which gas is burned and a heat exchanger is installed is called the firebox or combustion chamber. It can be of an open type (communicates with airspace premises) and closed type (sealed combustion chamber).

Leading brands of gas boilers

AEG, Bosch, Buderus, Vaillant, Viessmann, Wolf are German manufacturers. The products of these brands are high quality and the most expensive.

Alphatherm, Ariston, Baxi, Beretta, Biasi, Ferroli, Hermann, Lamborghini, Caloreclima, Nova Florida, Saunier Duval are Italian manufacturers of gas heating equipment.

Chaffoteaux, Chappee, De Dietrich, Frisquet are French companies.

Roca - Spain.

Termet – Poland.

Protherm - Slovakia.

Electrolux - Sweden.

It is impossible to say unequivocally which gas boiler is better. The products of these brands are very diverse in terms of automation level, energy dependence, maximum power, functionality and price.

Electric heating boilers

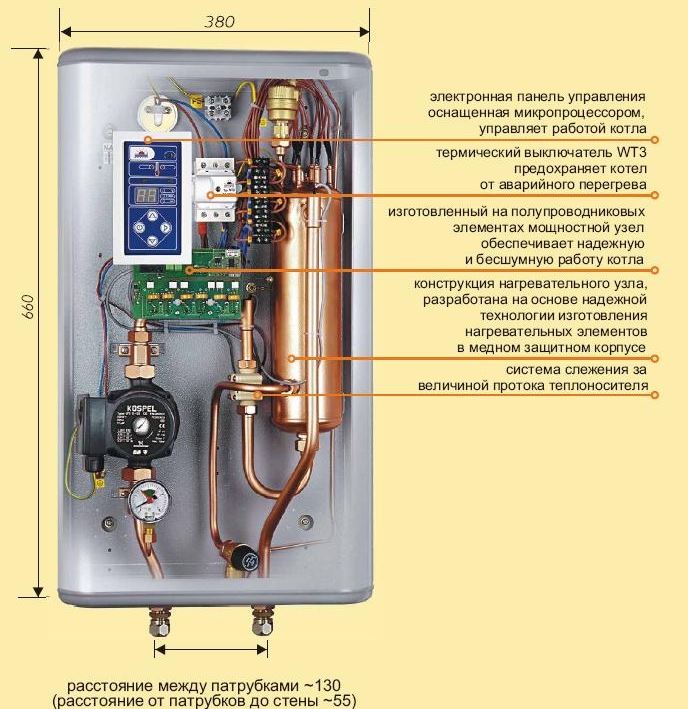

Units that convert electricity into thermal energy coolant are called electric boilers. Their feature is high level automation and operational efficiency. The efficiency can reach 98%, which means that almost all electrical energy is converted into heat.

According to the method of heating the coolant, electric boilers are divided into three types:

- Tension boilers - their operating principle is similar to how they work electric kettle— the water is heated by the heat.

- Electrode boilers - for heating they use electrodes that transmit electric current water and under its influence intense heating occurs.

- Induction boilers heat the coolant through the induction process. The induction coil is located in a sealed compartment, and heating is produced by a core around which the coolant circulates.

Electric boilers can also be single-circuit and double-circuit, suspended and stationary, single-phase and three-phase.

Brands of electric boilers

- PROTHERM;

- RUSNIT ELECTRIC BOILERS FROM 3 TO 100 KW;

- WARMOS-5–60. COMFORT CLASS;

- EVAN S1–5-30. CLASS STANDARD;

- ELECTRIC BOILERS DALINE PTE. PRODUCTION — DAKON (CZECH REPUBLIC).

Comparison of gas and electric heating

- Gas is cheaper than electricity.

- Gas boilers are capable of operating in energy-independent mode.

Even non-volatile boilers are provided with the system automatic control and protection. This is ensured by the presence in their design of a small generator that supplies power to the electronic automatic system.

- Electric boilers use energy more efficiently, as they have more high efficiency.

- Electric boilers are easier and cheaper to install than their gas counterparts.

- Both types of heating boilers must be registered with the relevant authorities, but only gas boilers must undergo annual certification (paid) and possibly repairs.

- Gas is an explosive equipment, therefore, to ensure safe operation it is necessary to purchase additional equipment (gas analyzers).

For example, purchasing an electric boiler requires less cost than purchasing gas equipment with all the additional elements. Now let's look at 2 options for using boilers:

- Heating a small apartment requires no large quantity energy for heating, so the price difference between the costs of purchasing equipment will pay off for several years.

- Heating a private home requires a large amount of heating energy, so the difference in price when purchasing equipment will pay off within a few months.

Electric heating is best used in small-sized and well-insulated apartments, and gas boilers are perfect for large private houses with high heat losses.

The choice of the optimal type of heating determines not only the cost of maintaining the house, but also the level of comfort of living in it. When choosing a heat source for your home, you must make a calculation and do not forget that the system is installed for many years.

Important parameters for choosing a heat source

Which heating is better? The answer to this question will depend on what you choose as evaluation criteria, but three conditions are unconditional for any type of heating:

- The amount of thermal energy must be sufficient to ensure the standard temperature in residential premises.

- Start-up and operating costs should be minimal.

- Heating should be simple and safe to maintain.

When choosing between gas and electric heating, it is necessary to take into account several important parameters:

- distance of the gas pipeline,

- availability of an electrical network with the required power,

- dimensions of the heated room,

- heat loss through windows and walls.

Whatever heating system you choose, the main factor in energy saving will be the thermal insulation of the room and right choice highly efficient heating radiators. Proper and comprehensive insulation of a house can reduce the consumption of a thermal energy source by half. And if you purchased, the savings will be even more significant.

Electric heating systems

If your house is not gasified, then the most profitable option would be installation electric heating. The most common heating system is using a double-circuit electric boiler in a single heating and hot water system, when the coolant is heated by heating elements.

The heating system can be installed with the installation electric radiators heating, and in this case, electricity is converted into heat directly, without heat loss for heating water.

Advantages:

- electric boilers more convenient to maintain,

- start-up costs vs. gas boiler an order of magnitude less

- ease of management and registration of permits,

- compactness of the equipment.

Flaws:

- the production of a unit of thermal energy using electricity is 8-10 times more expensive than gas,

- the need to install protective devices for the electrical network,

- The stability of domestic electrical networks is not very high.

When designing electrical networks, a certain power quota is allocated for each housing construction. And it may not be enough to connect your heating system on electricity. In this case, it is worth considering the option of combining an electric and gas source of thermal energy.

Gas heating systems

The best option for heating a private house if there is a main gas pipeline would be a gas boiler with a storage tank for hot water supply, a water heating system and a heat pump.

Advantages:

- the initial investment pays off in 2-3 seasons due to lower energy prices,

- Gas outages are much less common than power outages, so the stability of the heating system will be higher.

Flaws:

- higher starting investments compared to an electric boiler,

- high costs for permitting and design documentation,

- the need for maintenance and monitoring by special services,

- the need for gas supply and chimney installation,

- bulkiness of heating equipment,

- installation of a gas boiler is permitted only in a separate room.

It must be remembered that the calculation of economic efficiency always includes two main parts: one-time investments at the start and operating costs. And here are the costs of electrical and gas heating diametrically opposed.

Choosing a heating system for different types of houses

Given the instability of centralized heating systems, many apartment residents are trying to switch to autonomous heating. And in this case the best option electric heating will become possible due to the compactness of the heating equipment. In this case, there is no need to install a powerful ventilation system, a regular hood is enough.

For country houses and large-area cottages in the presence of a main gas pipeline best choice There will be a gas heating system. In addition, in villages, electrical networks are often not designed for increased load, so installing electric heating is simply impossible.

Heating wooden house a gas boiler requires additional permits. That's why homeowners are increasingly choosing electrical systems heating, giving them preference for reasons fire safety, environmental friendliness, ease of installation and registration of permits.

Modern heating systems allow you to choose the most profitable option for housing of any size, in apartment buildings and country houses. And by contacting the specialists of VivaldoRadianjri, you are guaranteed to receive a highly efficient and safe heating system.

The problem of heating apartments and country houses was, and is, one of the most pressing problems. Along with centralized systems heating systems are widely used and autonomous systems. There are several options for heating systems, but, for some reasons, the most common option for heating systems is the so-called radiator system. The main elements of such a system are a heating boiler and a system of pipes and heating radiators, which are designed to transport the coolant. In this article we will talk about which boiler to choose for a country house.

The main element of the system is, of course, the heating boiler. Heating boilers, for heating systems are classified according to the type of fuel used. It can be gas, solid fuel, liquid fuel or electricity. Heating boilers vary in power, which is indicated in kW. Thus, you can choose a boiler for small apartment and for a large home or office.

Produced by modern industry domestic boilers, thanks to built-in regulators, are characterized by high efficiency and, due to complete combustion of fuel, are practically harmless to environment. As a rule, such boilers are equipped with a number of additional equipment that performs the functions of water heating, forced coolant circulation and automatic control mode.

When choosing heating devices, several important factors must be taken into account.

In a radiator heating system, the room is heated by convection warm air Therefore, a device such as a heating radiator should be as open as possible to ensure better convection in the room.

The most common heating devices are radiators. They can be cast iron, steel, bimetallic and aluminum.

Along with traditional systems, heating systems are also beginning to be used, in which heating element serves pipes with hot water, which are mounted in the floor screed. Warm floors have several advantages over traditional radiator systems. Such a system does not require strong heating of the coolant; to ensure a comfortable climate, a coolant temperature of 50-60 degrees is sufficient. This system provides more uniform heating in the room.

Electrical

An electric boiler is perhaps the safest of all types of boilers. Such a boiler does not require a separate room and the construction of a chimney. Due to the simplicity of the device, it is very durable and has no harmful emissions into the atmosphere.

Electric boilers with a power of up to 12 kW are produced in single-phase and three-phase versions. Boilers of higher power are usually produced in three-phase versions. The main element of an electric boiler is a heat exchanger in which conventional electric heaters (Heaters) are located.

An important advantage of such boilers is their ability to do without constant maintenance and periodic cleaning procedures, which are typical for gas and other types of heating boilers.

Despite all these advantages, electric boilers have a rather limited distribution. This is due to the fact that connecting such a boiler requires the availability and accessibility of 15 to 40 kW of electricity. Not every section of energy lines has such an opportunity. In areas remote from large settlements, such a possibility does not exist at all.

Availability of a trunk gas pipe It doesn’t make you think at all about choosing a heating boiler because... the cost of gasification will justify itself many times over. Gas today is one of the cheapest types of fuel. It is no coincidence that the lion's share of all boilers sold on the heating equipment market is occupied by gas boilers. This group of boilers is presented in the heating equipment market in a very wide range. The main types of such boilers are wall-mounted and floor-mounted. Despite the same parameters, wall-mounted and floor-standing boilers have significant differences.

Floor-standing gas

Floor-standing boilers are considered a traditional manufacturing option. This option has stood the test of time, and nothing has changed in the design over the years. The main element, the heat exchanger, was manufactured in two versions and is still being manufactured.

Debate about which is better? Steel or cast iron are still not silent. Each material has its own advantages and disadvantages.

So, to the disadvantages cast iron heat exchangers, one can attribute their fragility, as a result of which cracks appear during careless transportation. With prolonged use of hard water, damage to cast iron can occur.

The advantage is considered to be non-susceptibility to corrosive processes and better heat transfer compared to steel.

The disadvantage of steel heat exchangers is their susceptibility to corrosion and shorter service life. Among the advantages we can highlight more light weight and shock resistance.

Floor-standing gas boilers are produced with two types of burners. Gas boilers with atmospheric burners and inflatable burners. Atmospheric burners are simpler to design and therefore cheaper. In addition, they are distinguished by quieter operation.

Boilers that are equipped with inflatable burners have higher efficiency. This burner is distinguished by the fact that air is forced into the combustion chamber. The amount of supplied air is adjusted automatically, depending on the operating mode of the boiler. Inflatable burners are several times more expensive than conventional atmospheric ones. Such burners produce significant noise, but at the same time, when using an inflatable burner, you do not have to worry about the stability of the gas pressure in the system.

Important! In conditions of frequent power outages, such a boiler parameter as its independence from electricity comes to the fore. This independence can be achieved in two ways.

The first implies complete absence automatic devices that need electrical power, and the second method, which is more promising, is the use of a heat generator.

Such a thermal generator will generate heat from electrical energy, which is necessary for work automatic systems. Gas boilers are usually manufactured in single-stage and two-stage versions. The single-stage version is capable of operating at one power level, and the two-stage version at two levels.

There is also an option with smooth power control, which is the most popular. This power modulation allows for the most economical use of energy resources.

Wall gas

Wall-mounted gas boilers are the result of progress in the field of heating equipment. Everything appeared in these devices latest developments in the field of heating equipment. This seemingly small building contains everything that is necessary for the operation of the heating system, and many residents of our country choose this type of boiler.

Wall-mounted boilers are produced with natural draft, when combustion products are removed through a chimney, and with forced draft, when combustion products are removed using a built-in fan. Such boilers do not require a separate chimney; you just need to make a hole in the wall and use a corrugated pipe to remove combustion products.

Wall-mounted boilers differ quite simple installation and less than floor-standing boilers at a price. This class of boilers fits into any interior without violating any rules or regulations. Compactness allows you to place this unit in a very small space.

Almost all modern wall-mounted boilers are equipped with automatic devices that provide them safe operation. This list includes temperature sensors, flame sensors, traction control sensor, etc.

The power of wall-mounted gas boilers varies from 12 to 42 kW, which allows them to be used for both small apartments, and for country houses. In addition, wall-mounted gas boilers are quite economical; their use can reduce gas consumption several times compared to centralized heating systems.

Liquid fuel

In the absence of access to main gas and to electrical networks, the heat supply problem can be solved by choosing an oil-fuel boiler. The fuel for such boilers are products of the oil refining industry, mainly diesel fuel. Such boilers are most often made in a floor-standing version.

Heat exchangers of liquid fuel boilers, as well as gas floor boilers, are made of cast iron or steel. Only forced-air burners are used. The models of burners used can be single or two-stage. The use of a two-stage burner increases the service life of the boiler.

Attention! The use of inflatable burners in diesel boilers makes them dependent on power sources. In such boilers, to switch to another type of fuel, such as gas, it is necessary to change the burner.

Diesel boilers are available with one and two circuits. Double-circuit gas heating boilers have a built-in hot water boiler or instantaneous water heater. For uninterrupted operation of a diesel boiler, it is necessary to have a special container for storing fuel reserves. The volume of the container depends on the needs of a given system. Such containers are made of metal or polymer materials and have different volumes.