Specifications

Type of heating boiler gas, convection Burner

Combined boilers wood / gas, firewood / diesel, as a rule, are supplied without a burner in the kit. The boiler will operate on solid fuel and it is additionally possible to purchase an appropriate burner for operation on gas or diesel fuel. For a diesel/gas combi boiler supplied without a burner, you must purchase and install an appropriate burner, because the boiler will not work without a burner.

gas Number of circuits single-loop Max. thermal power

Power is the main parameter when choosing a heating boiler. It is necessary to calculate the power of the heating system individually for each house, since it depends on the heated area, the heat loss of the house, the average temperature in the region during the cold season. Glossary of terms for the category Heating boilers

10 kW non-volatile yes Combustion chamber open Heated area 100 sq.m efficiency 90% Control

The heating boiler can be electronic or mechanical control. Also, manufacturers may offer to purchase one of several control panels to choose from for the heating boiler. The control panel can be purchased separately or when purchasing a heating boiler. It is important to remember that the boiler will not work without a control panel. Glossary of terms for the category Heating boilers

mechanical Installation floor Primary heat exchanger material steel Fuel

Fuel for solid fuel heating boilers are: firewood, pellets, coal, peat, coke and briquettes - wood, coal, peat. Liquid fuel boilers can run on diesel fuel, fuel oil, waste oil. Combined heating boilers can use solid fuel as the main fuel, as well as operate on natural gas or liquid fuel. Glossary for the category Heating boilers

natural gas Consumption natural gas 1.19 cu. m/hour Rated pressure natural gas 6 - 18 mbar Heat carrier temperature 40 - 90 °С Max. water pressure in the heating circuit 3 barWe bought a boiler Signal KOV-16 ST with a water heater. We've done all the heating but haven't turned it on yet. I have a question: Is it possible to turn on the heating if we have not yet set up water through the water heater? water has not yet been

Boiler signal stpv 12 kw, it has been working for 3 seasons, while everything is fine, but above 60g. It doesn’t pick up the temperature, when the regulator is turned on to the maximum, the boiler works constantly, the automation does not reduce the gas supply, which is why it climbs 1500 cubic meters in a month.

Obviously not enough power.

16 kilowatts is identical in size, but the burner itself is 16 kW. costs four thousand kopecks.

What is the best thing to do to increase the power of the burner.

Replace large bore nozzles, or ream these.

Move the stop of the regulator as described above.

Do I need to change something else or is this enough manipulation.

Specialists advise something. So as not to buy a 16 kilowatt burner, which costs like the floor of a boiler.

Thanks in advance

SIMILAR SITUATION. THE PROBLEM IS MOST LIKELY IN THE REGULATOR. MY SON LAST WINTER SOLDERED THE WIRE FOR THE SOLENOID. THE SOLENOID DOES NOT ACTIVATE AND THEREFORE THE GAS VALVE DOES NOT OPEN. TODAY THE BOILER AGAIN STOP WORKING. NOW I SIT AND LOOK FOR SPARE PARTS FOR THE BOILER. GOOD LUCK TO YOU ALL. (FOR INFORMATION: AT THE BOTTOM PART WHERE THE VALVE TURN HANDLE IS THE RED WIRE OUT. INSIDE THE REGULATOR THERE IS THE COIL WHICH RETRACTS THE SOLENOID)

I BOUGHT A KOV 10 ST FOR FOUR YEARS I WORKED WITHOUT PROBLEMS IN THE BEGINNING OF THIS WINTER THE DRIVING IS LOST. HOW THE WIND BLOWS THE BOAT IS GOING DOWN ADVISE HOW TO CORRECT THE SITUATION YOURSELF. THANK YOU IN ADVANCE.

Hello. I can use the KOV 12.5 SPVSsignal. working for about 10 years. This winter, he began to smoke, when the temperature rises, the smoke does not go into the hood, but into the boiler room. the chimney runs great. Please advise what can be done!

Boiler type SPV can be cleaned without dismantling. I have done this so many times. First, we remove the burner so that it would be possible to crawl up to the firebox from below. Secondly, with the help of an antenna cable, we clean one of the cavities of the furnace from the top. As soon as the cable comes out from below, we attach a rag to it and pull it back up. Laborious, but really cleans. Developed a client base in this business. In general, the boiler correct operation should not smoke. If you have any questions about "Signals", call 8-800-200-52-55 from 8.00 to 17.00 Moscow time from Monday to Friday. The call is free throughout Russia.

The same thing happened to me this winter. There is draft in the pipe, and the burnt gas is knocked out from the bottom of the boiler into the room. Removed the chimney from the boiler. I saw that the heat exchanger was clogged with soot. Since the designers of this miracle did not provide for the possibility of cleaning the heat exchanger without complete dismantling boiler with a drain of chemically treated softened water, had to be blown compressed air through right in the room. Naturally, after such a cleaning, the entire boiler room was covered with a layer of soot.

Good day everyone!!!

It will be about the fact that the apartment needs to be replaced with a gas boiler, a one-room apartment of 35 sq. m. Familiar gas workers advise It is the brand "Signal" that spare parts are available, unpretentious, economical, efficiency is a number higher than that of other boilers. It is also advised to take the model not 6.5, but 10, more precisely "SIGNAL 10" for 80 kV, which will make it easier for him to work, without straining. Please advise whether it is worth taking for a larger cubic capacity? And does this firm "Signal" deserve trust? I will be grateful to everyone in advance! Interested in a gas boiler without hot water also without a pump. We need a practical, not whimsical, reliable boiler without unnecessary troubles! Kustanai Kazakhstan.

Read the reviews, I bought a signal of 12.5 kV, everyone writes about the problems of the signal, 1- it doesn’t pick up temperature well. I don’t advise, it’s a constant headache, it goes out and clogs up, it’s been working for 2 months, I’ve suffered terribly with it, I’ll winter the season and throw it to hell, this is not a boiler.

Hello! Please tell me what's wrong with my boiler. I have had a double-circuit gas boiler KOV-10SPV SIGNAL for 8 years already, the thermostat has changed several times. And this year, some incomprehensible things started with him, I set the temperature to 60 degrees in the house, it becomes cool even if it is -5 degrees outside, while the water from the tap flows cold, if you set the temperature to 80-90 degrees, then the house is warm in frost -30 degrees , and the water from the tap flows hot but does not cool quickly even with a small pressure, with all this, if you need to wash yourself, you have to turn off the heating, and if you forget to turn on the heating later, the water in the expansion tank starts to boil. Please help, thanks a lot in advance.

Hello people! Please help, we have little gas pressure, but not to say that the wick, gas burns well on the stove, but I suffer from a gas boiler Signal Kov 20, 710 Minisit valve burner, and during ignition the arrow rises to 1.0-1.5 . First it lights up and then automatically turns off! Tell me how to adjust or adjust so that the gas burns! [email protected]/ I would really appreciate it!

after 8 years of work, something similar began to happen to me - at the maximum, but it's cold. I had to call a gasman, he tore off 450 rubles from us, and then it became a shame, it turned out that it was so easy to solve this problem on our own. If anyone is interested I will describe how.

Over time, automation sags there and the gas pressure on the burners is less. Remember the wheel that you use to set the temperature? In the extremely open position, there is a stop (pin) that prevents the gas from opening more strongly. So this emphasis must be moved further, for this, pry off with an awl and remove the retaining ring, it is located with inside this wheel. Then shift the emphasis somewhere on the turn and put back the retaining ring.

I ask for help: The Angels 18t signal worked normally, and now 1) when using hot water, the pressure drops 2) and after replenishing after a while it goes off scale and starts to drip (the air in the expansion tank is normal). The first one is very surprising, really the heat exchanger lost weight in a month. What is it, tell me?! Thank you!

What is a "thermal generator", in general, it is often called simply a thermocouple (by analogy with those used in gas stoves and instantaneous water heaters- columns), another thing is that this thermogenerator uses several thermocouples combined into a thermopile, which is placed in a stainless steel tube. By itself, the thermogenerator is designed to provide an autonomous electric power supply to el. the circuit of the boiler automation systems (thermal electromagnetic valve, thrust sensor and limit temperature sensor), in other words, it generates el. current...

So, the end of the steel tube of the thermogenerator (which, according to you, periodically burns out), during the operation of the heating boiler, is in the flame of the pilot burner and, accordingly, heats up from it. The steel tube of the thermogenerator itself is designed for such heating, it is another matter if it starts to heat up much more than usual, and this can happen if the combustion products are not removed from the boiler furnace space in a timely manner (the draft at the boiler outlet is not enough) and an "increased temperature stagnation" is formed in the igniter zone, which leads to the burning of the steel tube of the thermogenerator.

On the other hand, did you yourself see, with your own eyes, so to speak, that the steel tube of the thermogenerator really had a mechanical destruction of the "working end" or did the repairmen who came to you tell you about this? The fact is that the situation I described, if it can happen, is extremely rare. If it really happens with a certain frequency - deal with traction. Much more often, a periodic “failure” of a thermogenerator occurs in the following cases:

- poor contact between the thermogenerator and the thermoelectric valve (fault is eliminated by cleaning the contact between the thermogenerator and the thermoelectric valve base);

- thermo failed solenoid valve(fault is eliminated by its replacement);

- open circuit el. circuit due to a faulty state of the draft sensor or limit temperature sensor (fault is eliminated by stripping the contacts on the sensors, distribution block, tightening the loosely tightened "ground" bolt);

- failure of the thermogenerator after several years of operation of the boiler (the fault is eliminated by its replacement).

Installed the boiler "Signal" KOV-7 ST, with piezo ignition. As soon as I installed it, I tried to start it, the igniter ignited, but the main burners did not light up. A week later I wanted to drive away completely, did not want to start. What to do?

We bought KOV-7ST "Signal" on May 12, 2012, exactly a year later it leaked from the inside. The warranty period is 18 months. The boiler was installed by ourselves. The store requires an ACT from the gas workers (the cause of the breakdown). Gas workers cannot issue an ACT, since they do not service this boiler, we installed it!!! Tell me what to do and how to be ??? I don’t have such an opportunity to buy a new boiler every year !!! And is repair possible at all ???

Now all gas equipment under the contract is serviced by gas services. Do you pay a monthly fee for the service? If there is such an agreement, then the gas workers should all the more give a certificate of boiler breakdown, if not, then they should still give it only for payment.

If the gas equipment is installed by the subscriber (as in our case, the boiler), then the gas workers will not take responsibility for it. Gas boilers should be installed by the gas workers. So that later there would be no problems with the guarantee

It is unlikely that you killed him with your installation, but the gas workers have nothing to do with it either. But it could leak from the inside mainly for two reasons: either they were pressured by water pressure in the heating system, or the boiler was rotten with condensate ... If you don’t look at these two reasons, the next one will be the same ... read on Danko’s page.

I would like to know-SIGNAL-10 is not repairable? The gas worker advised me to purchase an arc boiler, citing that it bad boilers and will not undertake repairs. And I, like everyone else, have a problem - the handle of the regulator unit must be held for a long time until the scale reaches up to 4x when turning to ignition, it lights up and after 3 minutes. goes out. The ignition button does not work at all. SO IS THERE A POSSIBILITY TO REPAIR? Still, he only worked for 6 years, though with big problems

You can repair it, but if your gas workers do not know how to do this, then of course buy and install and operate and generally focus on the one that the gas workers CAN DO, or delve into it yourself. I have a Danko boiler, it works fine, but I also do it myself.

I bought a 25kw kovt 2.5 years ago. I worked the first winter without pretensions; in the second winter, problems started - it heats up to 90 - the burners turned off - the temperature drops to 60 and ... the automation did not work, you have to turn it on 2-3 times a night

There is a drawback when servicing the Signal, in order to clean the igniter it is necessary to remove the burner. And this is long and inconvenient. .the wiring that is soldered to the ground is very thin and unreliable, and the price of the coil is 700-800r..

I have a signal 10 burner GGU 12S-1, It heats the bath 75 sq.m. I had to tinker) I removed the factory nozzles from the cutter, this reduced the intensity of the flame for one by half, for the second about four times, the noise disappeared, it keeps a maximum of 85 without shutdowns, just right in the cold.

cov-20, 12 repairs in six years. I exhausted my whole soul! If my husband doesn’t change this year, I’ll cut it myself with a grinder. Neither heat nor hot water in the shower, just enough to wash the dishes. .about!

hello, I have cov 16 st the temperature rises to 80 and turns off to 60 then turns on again. this is a problem for my house. I need up to 90-100 then off at least 80. tell me pliz?

My sigal KOV40 has been working for probably more than 8 years, it heats the house 430 square meters. So far, no major problems. I guess I got lucky with him. Once the igniter began to smoke, I had to clean the air intake holes and that's it. Somehow it went out on its own several times. A smart gasman came and cut a strip of metal out of stainless steel and closed the space between the burners and the body on the front panel with it, the boiler did not go out anymore.

We have a ST Signal, it heated 30 squares, now it has begun to heat 60-70 squares, while on "!" heats up to 80 degrees and the burner does not turn off, what could be the matter ???

Good day to all. Given: Boiler KOV 31.5 ST production "Signal". The term of operation is 4 years. (declared 15 years!) The purchase price is about 17 thousand rubles.

BURNED!!! 2 holes of 3 mm in diameter with an interval of 10-15 mm of perfectly even rounded shape on the ledge of the ledge connecting the sandwich panels of the heat exchanger with the side "jacket" of the boiler. Flowed by the stream.

I do not exclude that there may have been a sink in the steel sheet or a point sticking of the electrode on the inside of the sheet during the assembly of the heat exchanger. (Sheet thickness 2 mm.) Due to the thinning of the metal in this place, the service life was reduced to 4 years.

I do not praise or scold this boiler. There are no complaints except for the noise. The absence of complex electronics and very good automation. All 4 years he did an excellent job with heating a cottage of 300 sq.m.

But I'm not ready to buy this product every 4 years.

Photo unfortunately did not. The heat supply was restored very quickly. (November in the yard) The boiler was successfully welded (the holes were very successfully formed not in an inaccessible place, but exactly horizontally above the burners on the side shelf 15 mm under the "sandwich" of the heat exchanger and were accessible when the boiler was overturned), but there is a very high chance that it remained Only 1 season that he probably will not survive.

Upon the final termination of operation of this particular boiler, a detailed photo report will be drawn up with purchase receipts and product passports and will be posted here. Unless, of course, the moderator removes this cry of the soul.

Uninterrupted warmth to all.

when the KOV ST boiler is ignited after starting the igniter, the flame burns, and when transferred to the “point”, as indicated in the instructions, the main burners should burn with a small flame, but do not burn. tell me what is the reason?

One of the leaders among domestic manufacturers of heating gas equipment is Signal-Teplotekhnika LLC, which is part of the Signal group of companies. This industrial group operates in the field of gas equipment, produces household and commercial models.

From the moment of foundation in 1951, the enterprise until 1990 was largest producer precision instruments for aviation and space purposes. With a change in market conditions, the company changes its direction of activity and retrains into the production of gas equipment.

"Signal" today

Since 1991, the company has been establishing mass production of gas equipment for domestic and industrial use. The signal plant is the largest in the Saratov region. Today, its products can be divided into three categories:

- Gas appliances for heating residential and industrial premises.

- Measuring instruments.

- Gas control automatics.

For household purpose(heating of houses and other residential premises) the signal company offers the following equipment:

- Double-circuit boiler of floor execution.

- Floor single-circuit boiler of increased power (up to 100 kW).

- Universal stoves for saunas and baths.

In addition to household heating appliances, the signal company manufactures and supplies transportable water heating and boiler plants with a capacity of up to 100 MW.

Among the achievements of the company it is worth noting:

Among the achievements of the company it is worth noting:

- Victory in the competition of regional manufacturers "Saratov Brand - 2008".

- Industry Leader Award in 2010.

- Official gratitude of the President of Russia in 2011.

In addition, it is worth noting that the products of the Engelsky signal plant comply with international quality standards and have the ISO 9001:2001 standard. Also, the company's products have passed federal certification and comply with GOST:

- R ISO 9001-2001;

- RV 15 002-2003.

A complete production cycle has been formed in the signal group of companies. Any gas boiler is completely manufactured and assembled at our own production facilities.

Advice! The double-circuit gas boiler of the signal trademark has a rated power of 10 to 40 kW and is optimally suited for heating both small dacha, and a cottage with an area of up to 350 sq. m.

Features of domestic boilers Signal

The heating boiler signal is suitable for heating and hot water supply of industrial premises and private houses of various sizes. High efficiency and high safety make the operation of this equipment convenient and economical.

All products are certified and have the following advantages:

All products are certified and have the following advantages:

- Nice pricing policy. Compared to others Russian manufacturers heating systems, the signal boiler has a lower price.

- High degree of safety of gas equipment. Own production tracking automation allows to ensure the reliability, safety and stability of the boiler.

- Modern design and comfortable operation. Built-in piezo ignition allows you to quickly start a gas boiler without the use of matches.

It is also worth noting the high efficiency, which is achieved by using two modes of operation. gas burner:

- Analog mode is for normal work boiler. In this mode, the burner does not go out and brings the boiler to 100% of the rated power.

- relay mode means significant savings gas due to the periodic operation of the burner (on-off cycle). In this mode, the boiler is capable of delivering from 25 to 50% of the rated power.

The lineup

All household heating devices signal are divided into two series:

Series standard

This series includes floor standing boilers single- and double-circuit versions with power from 6.5 to 100 kW. The reliability and durability of the operation of such a device is confirmed by numerous consumer reviews.

Let's look at some of the most popular models from this line. Boilers KOV-ST 7-16 kW have a tubular steel heat exchanger. Main specifications such a boiler:

- Ergonomic front panel allows convenient positioning of control sensors.

- Compact dimensions.

- Modified automation SIT, BRGG-1EM.

- Traction control sensors, flame presence, built-in thermostat.

Gas boilers KOV-ST 20-100 kW are characterized by increased power, suitable for heating large areas. Features of the device of this line:

- Automation Barg.

- Slit burners.

- Circulation pump.

- Possibility to connect a gas alarm and an electronic programmer.

Advice! The model with a rated power of 63 kW or more is equipped with Italian Honeywell automation. This makes it possible to achieve a reduction in gas consumption by approximately 15–20%.

comfort series

In the comfort series, the S-TERM signal boiler is presented. These gas appliances are available in three capacities: 10; 12.5 and 16 kW. The main technical characteristics and design features are as follows:

- The used analogue of the Italian burner Polidoro allows to achieve a significant reduction in noise during the operation of the boiler.

- High efficiency of at least 90%.

- Modern pilot burner.

- Built-in thermocouple.

- Automation Eurosit 630.

The safety of this heating equipment is ensured by the following sensors:

- gas pressure;

- control over the flame on the burner;

- thrust sensor;

- the built-in thermostat signals about an overheat of the heat carrier.

This floor-standing double-circuit boiler of the signal trademark allows you to achieve maximum comfort, providing uninterrupted heat and hot water supply. The products of a domestic manufacturer of gas boilers - the signal trademark is in demand among consumers due to low price for reliable, safe and durable heating equipment. The use of our own developments and the experience of foreign colleagues makes Signal a leader in terms of sales.

This floor-standing double-circuit boiler of the signal trademark allows you to achieve maximum comfort, providing uninterrupted heat and hot water supply. The products of a domestic manufacturer of gas boilers - the signal trademark is in demand among consumers due to low price for reliable, safe and durable heating equipment. The use of our own developments and the experience of foreign colleagues makes Signal a leader in terms of sales.

Boiler Signal KOV 10 SPV. Age - 8 years.

The new heating season has begun.

When starting the boiler "Signal9 the following happens:

1. The igniter normally warms up the thermogenerator and the arrow easily reaches the mark of 2.7-2.8.

At the same time, the boiler is in the "igniter9" mode; works fine for as long as it takes.

2. When the main burners are turned on, the readings of the thermogenerator device gradually decrease to 1.5-1.6,

which leads to the operation of the valve, the gas stops flowing and the boiler goes out.

3. If, at the instrument mark 1.8, the operating boiler is switched to the "igniter9" mode, then the arrow will again reach the mark 2.7-2.8

4. Last winter the boiler worked without comment.

I replaced the thermogenerator, but the picture of the behavior of the boiler remained the same.

I looked at the valve (electromagnet), which is connected to the thermogenerator.

mechanical damage did not notice, the spring and piston are movable (there is no wedge).

I looked and checked the contacts of the connection points of the thermogenerator wires - everything seems to be fine.

Tell me, what could be the reason?

Boiler Signal. The thermogenerator current drops

Boiler Signal. The thermogenerator current drops

The thermogenerator current is quite sufficient for operation in the "igniter9" mode, and in the operating mode

And here's why it's happening.

Boiler Signal. The thermogenerator current drops

Bereg wrote: The current of the thermogenerator is quite sufficient for operation in the “pilot”9 mode, and in the operation mode

burners, as it were, a thermogenerator sits down. those. It looks like the resistance of its load drops.

And here's why it's happening.

What is the current of a good thermogenerator? What are its limits?

Honestly, you need to look at the scheme already specifically. It's like treating a patient without testing. I think that the resistance does not change in the igniter and burner mode. There is an opinion that just in the igniter mode, the flame hits the generator directly, and in the burner mode, it goes to the side and the temperature drops. There, after all, the generator is probably a small thing.

You know what could be. In the burner mode, the standby flame goes out, which heats the generator, and the burners work. We've had that happen.

Boiler Signal. The thermogenerator current drops

Essentially.

It looks like an igniter jet.

Boiler Signal. The thermogenerator current drops

15 Sep 2015, 10:25

Similar problem. Did you find the reason?

Boiler Signal. The thermogenerator current drops

Shore wrote: Essentially.

Watching the process of "fading9 saw:

1. the thermogenerator is not completely covered by the igniter fire, only its end part (1/3. 1/4). Although, his position in the nest

and fixing nut in the normal state. Perhaps this is normal, because. the current is normal (in the “igniter”9 mode).

2. when the main burner is turned on, I noticed that the pressure in the igniter increases, the flame breaks. Those. the flame does not touch the body of the thermogenerator and the current gradually drops, causing after 1-2 minutes. actuation of the valve and attenuation of the boiler.

3. if the main burner position knob is turned slightly (about 30-40 degrees), then the pressure in the main burner and in the igniter decreases.

At the same time, the igniter flame “flows around”9 thermogenerator, the current does not drop and the boiler is working normally.

as an experiment, I changed the thermogenerator (the third in a row), but the picture does not change.

It is clear that the problem is not solved:

-before the boiler worked steadily at any position of the handle.

- it is not known how the boiler will behave further?

It looks like an igniter jet.

I cleaned the pipes and jets of the main burners.

When switching to the main burners, the igniter flame escapes from individual holes and ignites impulsively.

Could not unscrew the clamping nut of the igniter tube. For 8 years of work, she lost, apparently, well.

The design of the boiler is so flimsy. and no availability. I'm afraid I'll break it.

Haven't been able to get the jet yet. Tapping did not help, and diesel fuel / kerosene was not at hand.

I do not want to completely disassemble the gas control unit yet.

Have you solved the problem?

Section II. Boiler device. Main nodes and details.

1. Placement of sensors and nodes

Due to ongoing changes in the design of the boiler, the picture may differ from a particular boiler.

1 - BRGG-1E gas burner control unit, 2 - Gas burner device GGU, 3 - Heat exchanger, 4 - DBT draft safety sensor, 5 - DBT safety limit temperature sensor, 6 - Temperature indicator, 7 - URZ ignition burner operation indicator, 8 - TG-4 thermocouple generator, 9 - Gauge thermo-cylinder node, 10 - Shoe, 11 - Ignition unit, 12 - Solenoid valve

2. BRGG gas burner control unit

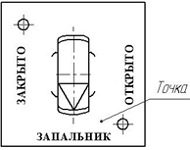

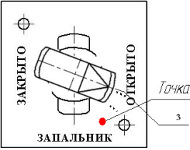

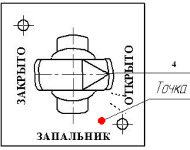

- It is possible to manually adjust the power of the main burner by setting the control knob to any position from the “red dot” mark to the “open” mark. In this case, the gas supply to the pilot burner is not reduced.

- The transfer of the control handle to the “closed” position is carried out by lightly pressing the handle.

Schematic diagram of BRGG-1E

3. Thermogenerator TG-4

Heating systems for country houses and country houses. boilers, geysers, water heaters — Repair, service, operation. Recommendations for assembly and installation.

Questions about malfunctions of heating gas boilers Signal

Question: Installed gas floor boiler KOV-6.5 Signal, works only in the "ignition" mode. When the regulator is switched to the combustion of the main burners, it works from 2 sec. (on the number 1) up to several days (on the number 6). At "7" it burns for months, until there is a heavy wind. When burning on the igniter, the flame is intermittent, which become more frequent and lengthen when the main burners burn.

The flame on the igniter is uneven, loud with "sneezing" sounds. For 6 months, gas workers have already ruined 2 boilers for me (MAG-1, KSG-8) in an attempt to correct non-existent causes, and the symptoms are the same for everyone. Today I put 2 “jumpers” in the hood, leaving a hole of a couple of centimeters, but the wind still walks on the flame. The hood is connected to former chimney brick oven. The apartment is on the second floor of a two-story building. In all other apartments of the house everything is the same, but no one has any problems.

Answer: If my memory serves me, the Signals have quite a decent automatic EVROSIT 630 with slot burners. She either has a flame separation, or problems with gas pressure in the network. To be honest, little is clear from the description of the problem.

It is possible that the thermocouple is not washed by the flame, so the boiler is turned off. Possible reason- separation of the flame on the igniter. Maybe the pull is too big. Gasoviki did not lose the igniter jet when they were dismantled? Has the air inlet screen on the igniter been cleaned of dust? Are the main burners clean? In any case, without seeing how the boiler works, you can’t name the exact reason.

Question: floor double-circuit boiler The signal lights up only at low temperatures. When switching to more high temperature, - on the igniter when the main burners are burning, the flame disappears. As for the hood, with a very strong wind it always blows out (extinguishes). By the way, all the neighbors' boilers from the very beginning worked with the automatics turned off, it's just that they (unlike me) don't care.

Answer: The following is waiting for you soon: due to the lack of oxygen and the increase in the gas through hole in the igniter, the gas will not burn well. As a result, the igniter, thermocouple and everything around it will be covered with a layer of soot. And the boiler will stop working altogether. It is possible that the thermocouple will also have time to burn out. It looks like the gas pressure is low.

There can be many reasons for this. A clogged filter in the gas valve, or the gas is connected to the boiler using a thin flexible hose for gas stoves. Or is it just low on the highway. You need to measure to find out for sure. The head on the chimney at the top needs to be looked at. How is it made? Is he there at all? You also need to look at how the chimney is designed relative to the building.

Question: A heating boiler was installed Signal KOV 10 SPV. Age - 8 years. The new heating season has begun.

At startup gas boiler The signal occurs as follows:

- The igniter normally warms up the thermogenerator and the arrow easily reaches the mark of 2.7-2.8. At the same time, the boiler in the “pilot” mode works normally for an arbitrarily long time.

- When the main burners are turned on, the readings of the thermogenerator device gradually decrease to 1.5-1.6, which leads to the operation of the valve, the gas stops flowing, and the boiler goes out.

- If, at the instrument mark 1.8, the operating boiler is switched to the “igniter” mode, then the arrow will again reach the mark 2.7-2.8.

— Last winter the boiler worked without remarks. I replaced the thermogenerator, but the picture of the behavior of the boiler remained the same. I looked at the valve (electromagnet), which is connected to the thermogenerator. I did not notice mechanical damage, the spring and piston are movable (there is no wedge). I looked and checked the contacts of the connection points of the thermogenerator wires - everything seems to be fine. Tell me, what could be the reason?

Answer: Most likely the igniter is clogged. Rather, the igniter jet. And, when the gas begins to go to the main burner, the pressure of the gas supply to the igniter decreases and, accordingly, the current generated by the thermocouple decreases, which becomes not enough to hold the EMC.

Question: Watching the process of "fading" I saw:

1. the thermogenerator is not completely covered by the igniter fire, only its end part (1/3. 1/4). Although, its position in the socket and the fixing nut are in the normal state. Perhaps this is normal, because. current is normal (in the "igniter" mode. Wink.

2. when the main burner is turned on, I noticed that the pressure in the igniter increases, the flames increase in size, move away from the thermogenerator, describing an arc of a larger diameter. Those. the flame moves away from the body of the thermogenerator and the current gradually drops, causing after 1-2 minutes. actuation of the valve and attenuation of the boiler.

3. if the main burner position knob is turned slightly (about 30-40 degrees), then the pressure in the main burner and in the igniter decreases. At the same time, the igniter flame “flows around” the thermogenerator closer, the current does not drop and the boiler works normally. as an experiment, I changed the thermogenerator (the third in a row), but the picture does not change.

It is clear that the problem has not been solved: before, the boiler worked stably at any position of the handle - it is not known how the boiler will behave in winter? -on the weekend I'll try to clean the jet and holes in the igniter pipe.

Answer: If it does not help, change the jet.

Question: I am engaged in the construction of a 2-storey residential building. Literally 3 days ago I started gas in the house. Yesterday there was a trial run of the boiler (Signal-25 cn hot water boiler, Junkers gas water heater, aluminum radiators, a common chimney for the boiler and the stainless steel column at the outlet with a diameter of 200 and a deflector at the end) and the following problem arose. The boiler works for 10-15 minutes, then it goes out.

Suspicion immediately fell on the chimney. before it goes out, a flame bursts out of the boiler inside the boiler room, and on the street, by the way, a strong gusty wind blows at this time. I called the specialists who installed the chimney - they checked the draft with a piece of paper in front of me - there is a draft. They advised not to fully open the handle “closed - igniter - open”, because. gas pressure is too high. Today I tried to start the boiler again, and it again died out several times. What can you advise, what else to check?

Answer: floor gas boilers The signal is very critical to traction. I've had this problem quite a few times myself. You start the boiler, after ten minutes it goes out. The problem was solved by opening the window to the boiler room at the time the chimney was warming up, as well as starting the boiler in the “point” mode, turning the handle not all the way to “open” but in an intermediate state, this point is there.

Question: I have a Kov-sts-16 signal boiler connected, the TG-4 thermogenerator constantly burns out, approximately once every 3 months. What it is?

Answer: What is a "thermogenerator", in general, it is often called simply a thermocouple (by analogy with those used in gas stoves and instantaneous water heaters - columns), another thing is that this thermogenerator uses several thermocouples combined into a thermopile, which is placed in stainless steel tube. The thermogenerator itself is designed to provide autonomous

electric power supply the circuit of the boiler automation systems (thermal electromagnetic valve, draft sensor and limit temperature sensor), in other words, it generates el. current.

So, the end of the steel tube of the thermogenerator (which, according to you, periodically burns out), during the operation of the heating boiler, is in the flame of the pilot burner and, accordingly, heats up from it. The steel tube of the thermogenerator itself is designed for such heating, it is another matter if it starts to heat up much more than usual, and this can happen if the combustion products are not removed from the boiler furnace space in a timely manner (the draft at the boiler outlet is not sufficient) and an “increased temperature stagnation” is formed in the igniter zone, which leads to the burning of the steel tube of the thermogenerator.

On the other hand, did you yourself see, with your own eyes, so to speak, that the steel tube of the thermogenerator really had a mechanical destruction of the "working end" or did the repairmen who came to you tell you about this? The fact is that the situation I described, if it can happen, is extremely rare. If it really happens with a certain frequency - deal with traction.

Much more often, a periodic “failure” of a thermogenerator occurs in the following cases:

- poor contact between the thermogenerator and the thermoelectromagnetic valve (the fault is eliminated by cleaning the contact of the thermogenerator and the base of the thermoelectromagnetic valve);

- the thermo-electromagnetic valve has failed (the fault is eliminated by replacing it);

- open circuit el. circuit due to a faulty state of the draft sensor or limit temperature sensor (the fault is eliminated by stripping the contacts on the sensors, the distribution block, tightening the loosely tightened “ground” bolt);

- failure of the thermogenerator, after several years of operation of the boiler (the fault is eliminated by replacing it).

Question: we have little gas pressure, but not to say that the wick, gas burns well on the stove, but with the Signal Kov 20 (710 Minisit valve burner) gas boiler, there are problems, and during ignition, the arrow rises to 1.0-1 ,5. First it lights up and then automatically turns off! Tell me how to adjust or adjust so that the gas burns?

Answer: Over time, automation sags there and the gas pressure on the burners is less. Remember the wheel that you use to set the temperature? In the extremely open position, there is a stop (pin) that prevents the gas from opening more strongly. So this emphasis must be moved further, for this, pry off and remove the retaining ring with an awl, it is located on the inside of this wheel. Then shift the emphasis somewhere on the turn and put back the retaining ring.

Question: I have installed a heating boiler KOV 12.5 SPV Signal. working for about 10 years. This winter, he began to smoke, when the temperature rises, the smoke does not go into the hood, but into the boiler room. the chimney runs great. What can be done with it!

Answer: The Signal boiler can be cleaned without dismantling. I have done this so many times. First, we remove the burner so that it would be possible to crawl up to the firebox from below. Secondly, with the help of an antenna cable, we clean one of the cavities of the furnace from above. As soon as the cable comes out from below, we attach a rag to it and pull it back up. Laborious, but really cleans.

Question: Gas heating boiler signal stpv 12 kW, it has been working for 3 seasons, while everything is fine, but above 60g. It does not pick up the temperature, when the regulator is turned on to the maximum, the boiler works constantly, the automation does not reduce the gas supply, which is why it climbs 1500 cubic meters in a month. Obviously not enough power. 16 kilowatts is identical in size, but the burner itself is 16 kW. costs four thousand rubles. with pennies. What is the best thing to do to increase the power of the burner? Replace large bore nozzles, or ream these? Move the stop of the regulator? Do I need to change something else or is this enough manipulation.

Answer: moving the stop of the regulator will not do anything. you can drill the primer on the nozzles to a larger diameter.

Question: The heating boiler is connected, the signal is 10 st; for two years it worked perfectly, it ignites and works as expected, but when the main burner is turned off, the igniter also goes out. Has anyone encountered such a problem?

Answer: Most likely, a spring has bitten in the GRBG block. The fix is very easy.

- unscrew the two screws on the cover with the inscriptions "closed", "open", "igniter".

- under the cover there will be two more screws, we also unscrew them.

— we take out a large spring and a cork valve.

- inside the tap, a spring hangs on the rod. Here it is most likely bitten by a split washer.

Another option is to cool the thermogenerator. It is necessary to bend the igniter so that its flame engulfs the thermogenerator.

Question: Problems during ignition, release the button, the wick immediately goes out, the replacement of the thermogenerator did not help. What can be done?

Answer: check the limit temperature sensor, or change the solenoid valve. Unscrews from below.

Question: We installed and launched a gas boiler kov-16-st signal - at first everything was fine, but then, with a strong wind, the boiler itself began to go out. we called the master, he examined the device and did not find any reason, and the boiler goes out and goes out - what do you advise me to do?

Answer: You need to pay attention to the following:

- Chimney. The length of the vertical section of the pipe from the boiler to the elbow must be at least 90 cm.

- The horizontal section of the chimney after the knee - no more than 50 cm.

- The chimney on the roof should be higher than the roof ridge, and the cap on the chimney should generally be at a height of 30-40 cm from the pipe cut.

- If everything is fine with the chimney, then this is most likely a large gas pressure. Need a regulator.

Question: The unit works with water at 1, it heats up to 110, why does it not switch to the igniter?

Answer: The thermostat is out of order.

Question: The floor boiler signal 25s is connected and connected. Once it went out, after a couple of hours it went out again and does not light up anymore. there is a solenoid valve and the thermocouple changed. put it back, cleaned the contacts all by zero. who else can tell? maybe a marriage in spare parts? or thermocouples for different models various?

Answer: If you have never been serviced in six years, then I advise you to pay attention to how the igniter burns. If the flame is small and white color, then it is necessary to clean the holes for the primary air supply from dust and call the master to clean (purge) the igniter gas pipeline ( copper tube) and igniter nozzles. The pilot flame must be of blue color. In this case, the thermogenerator (and you replaced it) will generate more EMF.

Question: tell me, I have Signal st-10 installed and connected in winter, there is a weak gas pressure, the temperature does not rise above 55, is it possible to replace my burners with burners 12.5 and will there be any sense?

Answer: If the gas pressure is low, then most likely when you replace the burner with a more powerful one, the following will happen: the gas will flow a little more to the main burners (at the same time, it will no longer be at the burner inlet), but at the same time the gas pressure (working) in the gas distributor will decrease and the flame on the igniter (wick) will become smaller, the thermogenerator will warm up worse, the thermo-EMF will be less, the boiler will start to turn off completely with the igniter, and this is fraught (if you are not present) freezing the heating system. Boiler (any) - it consumes gas, cannot produce it.

Find out the cost of construction Ask a question Photos Reviews

- about the project