On modern market heating equipment there are many devices differing in design features, price and manufacturer. Therefore, many are interested in what you need to pay attention to when choosing gas boilers, rating of the best in its price category and class.

When compiling a rating of the best gas boilers for the home, they first take into account the popularity of a particular brand, the popularity and demand of the product. How reliable is it and is it in demand? different countries can be judged from sales and service center reports, as well as from reviews from numerous customers.

Each of the above companies deserves to take first place and lead the rating of the best wall-mounted or floor-mounted gas boilers, single- and double-circuit, that is, in their class. All of them have a solid reputation, have been on the market for a long time, and their products are well known to consumers.

Noting the best Russian-made gas boilers, the rating is headed by the following brands: Irbis, NevaLux (OJSC Gazapparat), ZhMZ, Conord (ZAO Rostovgazaparat).

The best wall-mounted gas boilers

As is clear from the name of the type of boiler, they are structurally designed for installation on a wall. In most cases, they are produced with relatively low power - up to 35 kW. This is explained by the fact that they are equipped with a copper heat exchanger, which is not intended for high temperatures.

Useful information for those who are interested in wall-mounted gas boilers, the ranking of the best is headed by Bosch products. Special attention deserves the Bosch GAZ 600 WBN model. The advantages include:

— compact dimensions;

— relatively high efficiency — up to 93%;

— equipped with a turbocharged combustion chamber;

- efficiency;

— availability modern system electronic protection;

This model is the optimal choice for heating a small private house or apartment. Among single-circuit boilers, the best wall-mounted gas heating boilers, along with Bosch, are topped by models from another well-known manufacturer - Baxi, in particular ECO FOUR 1.14, LUNA 3 Comfort 1.310 Fi, BAXI LUNA DUO-tec MP 1.35.

Single-circuit boilers

Single-circuit boilers are used only for heating premises for various purposes, this means the basic configuration. But in principle they can also be used to serve hot water, if you additionally equip it with a boiler.

It is important to take into account design differences. For example, a double-circuit boiler heats running water, and in order to automatically turn on the hot water system, it is necessary to provide a sufficient level of pressure to the water flow at the inlet. Therefore, it will not be possible to use hot water sparingly.

Installation of single-circuit boilers is optimal for large areas in which water intake devices (showers, taps, etc.) are located at a decent distance from the boiler. This is explained by the fact that, according to technical conditions, an additional pump cannot be connected to a heating system with a double-circuit boiler.

The rating of the best gas heating boilers among “single-circuit” ones is headed by: BAXI SLIM 1.490 IN, PROTHERM MEDVED 50 KLZ.

The latter is equipped with a built-in boiler with a capacity of 110 liters, so there is no need to buy additional components. The advantages of MEDVED 50 KLZ include the following factors: efficiency, high efficiency - up to 92%, which is a very high indicator for this type of equipment, as well as a high degree of electrical protection - class IP40.

Rating of the best double-circuit gas boilers

Double-circuit gas boilers are universal and are excellent for heating homes and providing hot water supply (hot water supply). Most often they are produced in a floor-standing version, but if desired, you can also find a wall-mounted double-circuit boiler. Distinctive feature double-circuit boilers is the presence of an additional heat exchanger.

— Danko 10X;

— Vaillant atmoVit INT 164-564/1-5;

— BAXI SLIM 2.230.

This gas boiler is called one of the most reliable that are presented on the modern heating equipment market.

Their advantages are: high efficiency, reliability, the presence of an automatic protection system, efficiency, and long service life.

Considering the best wall-mounted double-circuit gas heating boilers, the rating is headed by the following models: Baxi (Baxi) LUNA 3 310 Fi, Baxi (Baxi) MAIN FOUR 24,

Baxi (Baxi) ECO FOUR 24, “Jaguar” and “Lynx” (manufacturer Protherm).

Floor-standing gas heating boilers for country cottages

Floor-standing gas boilers are more in demand, as they can be used with virtually no restrictions, which is explained by the wide range of heating equipment in this class. They are characterized by much large sizes and power, compared to wall-mounted ones. The latter are recommended for installation in cases where the area of the room is very limited.

Floor-standing gas boilers can be called the optimal solution for heating premises for various purposes with an area of 100 - 600 m2. Today there are many models of such equipment with various configurations on sale. But the main classification of floor-standing boilers

carried out by power, by the type of coolant used, by the number of circuits, by type of burner, by energy dependence, by the material from which the heat exchanger is made, by type of draft.

According to the latter indicator, gas boilers are divided into atmospheric and turbocharged. Atmospheric ones are characterized by high reliability, simplicity and long service life, almost complete noiselessness and low cost.

Boilers equipped with a turbocharged burner are much more expensive, but have higher efficiency rates.

1) BUDERUS Logano G125-32 WS.

Important. This model is characterized by its versatility, as it can operate not only on gas, but also on diesel fuel and high efficiency, which reaches 96%.

Other advantages of Logano G125-32 WS:

— combined (electronic-mechanical) type of control panel;

— the ability to select configurations, including modules used to expand functionality;

— minimum noise level during operation.

The latter property is ensured due to the fact that the amount of air supplied to the system is optimized. Plus a very affordable price for heating equipment in a private home.

2) VAILLANT ATMOVIT INT 164-564/1-5.

This German-made gas boiler is the most suitable option for heating installation country house relatively small area, no more than 120 m2. Advantages:

— equipped electronic system self-diagnosis;

— good indicator Efficiency - 94%;

— compactness;

- relatively light weight - 82 kg.

The only drawback, according to buyers, is that VRC 420S regulators must be purchased separately, since they are not included in the standard package.

3) ALPINE AIR FL-8 - the optimal choice for heating small spaces (workshops, country houses, garages, etc.), the area of which does not exceed 50 m2.

![]()

The model is characterized by a fairly high efficiency - 94%, reliability, efficiency, compact dimensions (750X280X310 mm), durability and operational safety. The average gas consumption is less than 1.0 m3/h. An important advantage is the energy independence of the equipment. The downside is the spontaneous shutdown of the device when the gas pressure at the inlet drops below 13 mbar.

4) KUSATERM 10-20. It occupies a leading position in the rating among gas heating boilers for baths.

It is important to consider that the operating principle of gas boilers intended for installation in bathhouses differs quite significantly from conventional heating equipment

The advantages of this model include:

— quick heating of the stones, which is ensured by the presence of a fan;

— reliability, safety and durability;

— the boiler body practically does not heat up, which is due to the presence of thermal insulation made of FoamGlass;

— quick selection of the desired mode using the electronic control panel.

Despite the relatively high cost, the owners of Kusaterm 10-20 note that this boiler allows you to quickly prepare the bathhouse for procedures, and the process itself is pleasant and comfortable.

In general, when choosing gas boiler heating, it is necessary to take into account many factors, in particular: efficiency, reliability, safety of use, adjustability, rated power of the equipment, efficiency, cost and design features, and of course who the manufacturer is.

Considering all of the above, we can draw the following conclusions. Firstly, when deciding which gas boiler to choose for a private home, it is not enough to rely only on the rating of a particular model and manufacturer, but take into account its functionality and requirements. In particular, for houses equipped with hot water heaters or boilers, choosing a single-circuit boiler can be considered a rational option. In other cases, when in addition to heating in the house, you also need to provide hot water supply, you need to choose a double-circuit boiler of suitable power, which can be found out from the performance characteristics. Here are examples of suitable options for private houses of various sizes.

Once the type of heating boiler has been selected, you need to correctly select a device that will fully meet the requirements and have the appropriate characteristics, such as efficiency, power, pressure, operating temperatures, and area of heated premises.

Due to the fact that the range of products offered to consumers heating devices appeared large number With new, modified models of domestic and foreign production, having different characteristics and price levels, nowadays it is possible to replace the old boiler with a more economical, compact and aesthetic one without any problems. Many owners decide to “kill two birds with one stone” with such a purchase, that is, at the same time solve the issue of autonomous hot water supply. And this is not difficult now - they are offered a wide selection of double-circuit boilers.

However, such high market saturation often contributes to the “reverse effect”, that is, it makes choosing the optimal model a very difficult task. We will try to help with this - we will provide a list of devices that are consistently included in the constantly changing rating of double-circuit, wall-mounted and floor-mounted gas boilers. True, a reservation can be made: the authors deliberately did not award certain places to the listed boilers - simply so as not to interfere with the subjective factor in this issue. The defining criterion was positive reviews consumers who have already tried this technique in practice. In a word, the boiler models indicated in the publication can be purchased with close to 100% confidence in receiving a device of high build quality and with the expectation of its long-term operation.

Of course, when choosing any heating boiler, you need to pay attention to other criteria that affect quality and durability.

Basic criteria for choosing a heating device

Unit type by location.

Double-circuit boilers are divided into floor-mounted and wall-mounted.

- Floor-standing double-circuit gas boilers, as a rule, are designed for higher thermal output than wall-mounted models, so they are most often installed in houses with a large area. However, for such heating devices with a power of 30 kW or more, a separate room from the living area is required. Therefore, before choosing such a model, it is necessary to study not only the technical characteristics and operating rules, but also the standards for boiler room equipment.

On sale you can find models of floor-standing gas boilers that do not require power to operate - it is only important that there is a gas supply of natural or liquefied gas. Such variants of units are especially convenient for heating in houses located in rural areas, where power outages are not uncommon. The design of non-volatile boilers is quite simple, but very reliable; such units are more durable than boilers with complex automation.

The efficiency of modern floor-standing models is 90 percent or higher.

- Wall d Double-circuit gas heating appliances, as a rule, are compact in size, so they are convenient to install in small houses or even in a city apartment.

Since such a unit does not take up much space, it is usually placed on the kitchen wall, where all the communications necessary to connect it are located. For the operation of almost all models of wall-mounted heating devices, an uninterrupted power supply is required. The circulation pump, the automation unit, and, in models with a closed combustion chamber, the fans for air injection and exhaust of combustion products require power.

Naturally, installing a gas boiler in the living area of the house increases the requirements for the organization more efficient system ventilation.

Unlike floor-standing boilers, in which steel or cast iron heat exchangers, wall-mounted appliances, in order to reduce their weight, are often equipped with copper heat exchange elements.

The power of wall-mounted units usually varies from 9 to 30 kW.

Power of double-circuit boilers

In order for a heating and water heating device to be truly effective in operation, it is necessary to correctly calculate its power for a specific house or apartment.

Very often on the Internet you can come across a sign like this:

To be honest, such information, instead of a clear idea, can, on the contrary, raise a lot of questions in the consumer. Agree that the difference in price between 9 kW and 20 kW models will be quite significant, and the spread of options according to such a “coordinate system” is impressive.

In addition, this approach does not take into account the characteristics of the regional climate, the building itself and its individual rooms, the degree of glazing (that is, the number and size of windows) and many other important circumstances. Therefore, it seems more reasonable to carry out more thorough calculations, in which the calculation calculator located below can help.

The basic principle is that calculations are carried out for each heated room separately, and then the results are summed up. This, by the way, gives the owners another “preference” - having such calculation results in hand (and it is best to display them on a plate - for each room separately) it will be much easier and correctly to arrange heat exchange devices - radiators or convectors - in the rooms.

Calculator for calculating the required thermal power for space heating

The advantages of equipping a country house with a gas boiler are obvious: “blue fuel” is cheaper than electricity, and its stable supply instills confidence in the availability of uninterrupted heat. Therefore, today in our article you will see a rating of wall-mounted double-circuit gas boilers in terms of reliability because... This type of boiler is the most popular and in demand.

Double-circuit gas boilers solve two main problems:

- home heating;

- supplying consumers with hot water.

When choosing one or another unit, you need to rely on the structural elements:

- Combustion chamber. An open combustion chamber requires a separate chimney and a ventilation system that provides a guaranteed air exchange rate of 3-4 times per hour. In the absence of these devices, you should focus on a gas boiler with a closed combustion chamber.

- Burner type. In units produced by modern industry, three types of burners are used:

- atmospheric, the principle of operation of which is based on the pressure in the system;

- modulated, capable of converting the heating coefficient;

- two-stage, switchable to 40% energy load at maximum heating temperature of the coolant.

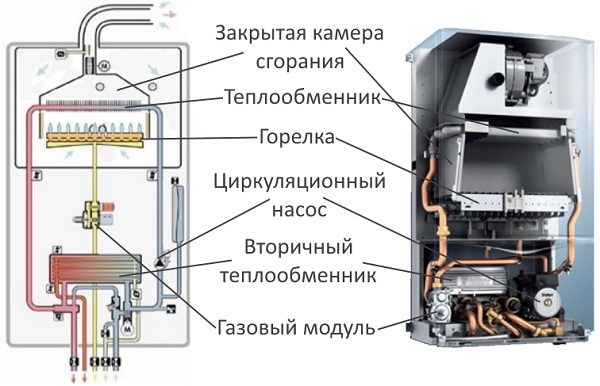

Diagram of a double-circuit gas boiler

Wall-mounted double-circuit gas equipment has compact dimensions, low weight and relatively low cost. It fits perfectly into small space, can be easily equipped with a chimney, and is also suitable for heating spaces up to 300 sq.m.

The line of these boilers of German origin is equipped with combustion chambers of closed and open types:

- Buderus Logamax U044 is equipped with an open firebox and draws air from environment. B vertically installed chimney combustion products are ejected, and the fan provides additional pumping of smoke.

- Buderus Logamax U042 24K has a closed camera. One of the advantages of the unit is the intake of air from the street or from the environment. Using a coaxial chimney (pipe within a pipe) will remove combustion products outside and allow fresh air to enter the room. This model does not have a water storage tank: you can get a hot stream using the flow method.

The combination of durability, frost resistance, adaptation to power surges, and increased noise insulation (≤36 dBA) place the unit at one of the highest levels of reliability and quality.

Buderus Logamax U042 24K, having a modulating burner and a double-walled heat exchanger, has a sufficient power amplitude - from 8 to 24 kilowatts, which allows the equipment to operate at a minimum pressure in the system, at which other units operate with errors.

Advantages:

- Silent;

- Economical;

- Safe;

- Easy controls.

Flaws:

- Installation of an uninterruptible power supply is required, otherwise when working on the network, for example, welding, errors may occur or the board may burn out;

- The built-in circulation pump is below the declared power.

Bosch Gaz 6000 W WBN 6000-24 C

The German company Bosch expanded its activities by launching the production of gas boilers in Portugal, Turkey and Russia (Engels). Wall-mounted varieties of units quickly gained popularity due to the popularity of the brand. The low price offer also played a significant role in consumer demand.

Bosch Gaz 6000 W WBN 6000-24 C has a closed combustion chamber (turbocharged boiler) and some advantages over other lines of well-known brands:

- equipped with a gas saving system (winter-summer);

- frost protection;

- equipped with a gas control system;

- providing protection against pump blocking;

- presence of weather-dependent automation.

Possessing a standard set of functional features and equipment, this model is quite competitive in the Russian consumer market.

Gas boiler from Bosch - acceptable budget option for the user who prefers a well-known brand at a low cost.

Advantages:

- Heats up quickly and well;

- Easy installation;

- Economical;

- Smooth ignition, many settings.

Flaws:

- Sometimes it produces errors; de-energizing the boiler for a few minutes helps;

- Pump vibration;

- The tubes in the differential relay accumulate condensate (error C4) and need to be purged.

Baxi MAIN 5 24 F

Baxi gas equipment from the Italian manufacturer has established itself as a full-fledged competitor on the Russian market. The MAIN 5 24 F model from Baxi represents the fifth generation of wall-mounted water heating units. The compact dimensions of the boiler allow you to find a convenient place for it in minimal space.

The main advantages of the presented model are:

- enhanced adaptation of equipment to the characteristics of conditions deviating from the standards;

- electronic protection against scale;

- ionization fire control;

- thermal power range – 6-24 kilowatts;

- frost protection;

- presence of a water pressure sensor.

Equipment safety monitoring and control devices are related indicators of the reliability of units.

Advantages:

- Convenient boiler control;

- Good automation.

Flaws:

- Noisy and not very economical because it starts often;

- The tube often falls off the pressure sensor.

Protherm Cheetah

European quality, durability and ease of control are combined in the Protherm Gepard gas boiler from Czech manufacturers. Possessing technical perfection, ease of operation, reasonable price and maintenance, this model is confidently gaining momentum among the Russian population.

The qualitative advantages of the Protherm Gepard wall-mounted boiler are characterized by:

- calculated efficiency – 92%;

- the ability to select a comfortable heating mode - “winter” - “summer” - “vacation”;

- equipped with a heat-controlled bypass (bypass channel);

- the presence of a three-way valve (control unit for maintaining the set temperature);

- the presence of an automatic air valve (device for bleeding air);

- frost protection;

- control of flame and draft in the chimney.

With the right approach to installing a boiler, the equipment can last for decades.

Advantages:

- Easy installation;

- Quiet;

- Reliable and easy to maintain.

Flaws:

- No service documentation;

- Dependent heating circuits. This means that if a person washes in the bathroom, then no heating is used for heating.

Navien DELUXE

The Navien DELUXE turbocharged gas water heating equipment manufactured in Korea has proven itself to have decent functionality, ease of use, and, most importantly, quality characteristics:

- the ability to heat water not only with flame, but also with combustion products (smoke);

- possibility of using coaxial and separate chimneys;

- presence of a programmable microprocessor;

- supply of frost protection;

- complete with auto diagnostics.

Important! As the smoke cools, condensation forms. When its volume in the boiler becomes high, the moisture is thrown out through a special outlet. A sewer pipe must be connected to it.

With the help remote control, included with the device, you can program a comfortable room temperature.

Advantages:

- Low price;

- Good remote control.

Flaws:

- Not a strong pressure of hot water;

- A bit noisy.

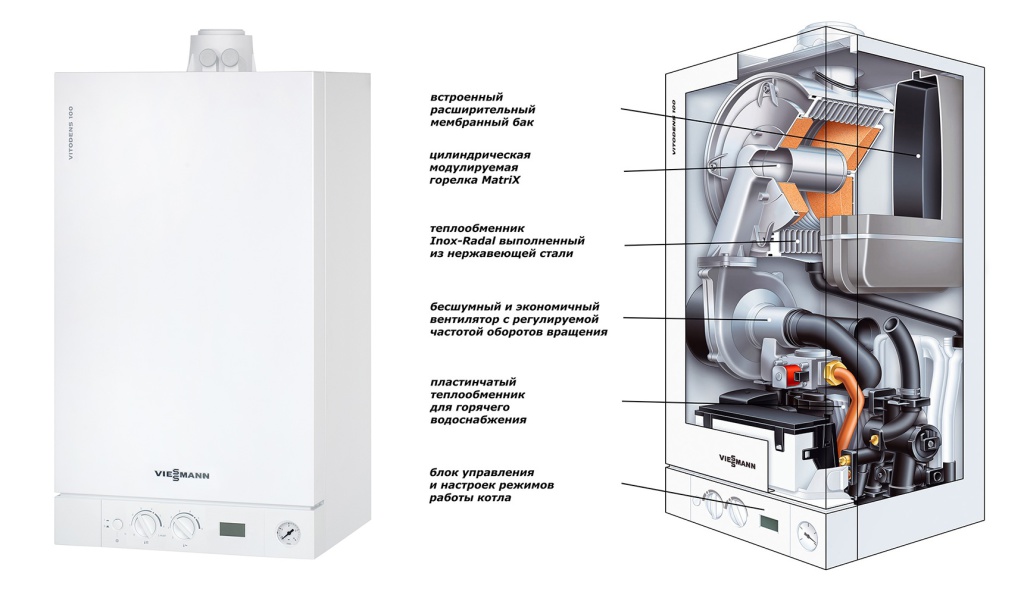

Viessmann Vitopend

When faced with the choice of purchasing one or another gas equipment, the consumer relies on financial opportunity, the technical equipment of the unit, its quality and functionality, as well as cost savings and environmental characteristics. German manufacturers of the Viessmann company managed to combine the listed parameters in Vitopend water heaters. Characteristics wall-mounted boilers of this brand are:

- combustion products contain a minimal amount of harmful components that are easily processed by plants;

- reduced gas consumption at high efficiency(for turbocharged models);

- The Vitopend line is characterized by two types of units:

- With a flow method for producing hot water.

- With a storage tank (up to 50 l), which allows you to save on energy and remain with hot water in the event of an unauthorized gas shutdown.

- quiet operation;

- possibility of using natural and liquefied gas;

- equipped with a work safety controller.

In the absence of central gas supply and power outages, you can choose a manually controlled boiler. This will allow you to organize a heating system using mechanical thermostat, independent of fluctuations in energy resources.

Advantages:

- Compact;

- Heats water perfectly;

Flaws:

- Not very reliable.

Oasis BM-16

A budget wall-mounted gas boiler made in China, Oasis BM-16, is designed to heat a room with an area of no more than 160 sq.m and provide hot water supply. It can operate on natural, liquefied and bottled gas. The guaranteed service life of two years is not the only declared advantage of the device:

- low cost;

- self-diagnosis (errors are displayed);

- frost protection;

- presence of an expansion tank with a volume of 6 liters;

- the ability to regulate the temperature of the coolant;

- built-in condensate drain;

- programmable timers.

The Oasis BM-16 boiler, like its European competitors, has the ability to install one of the types of smoke removal to choose from: coaxial or separate.

Advantages:

Advantages:

- Well made;

- Support for heated floors;

- Autodiagnostics.

Flaws:

- Not very powerful.

MORA-TOP Meteor

The efficiency of the Czech gas units of the Mora Tor company has once again proven its high competence and competitiveness by launching model range Meteor boilers. Among many, they stand out:

- affordable price offer;

- protection against power surges;

- modulation of flame combustion (gas saving);

- possibility of changeover to natural, liquefied or bottled gas;

- equipped with a temperature sensor;

- protection against gas pressure drop.

The improved series of MORA-TOP Meteor Plus boilers is equipped with automatic controls that can be freely adjusted to the consumer’s wishes. Automated control makes the equipment more reliable.

Haier Falco L1P20-F21(T)

Multi-level protection ensuring Chinese gas equipment Haier Falco L1P20-F21(T) uninterrupted operation, long service life and high quality Efficiency allows the device to compete in the market of water heater manufacturers. Features worth paying attention to:

- flame break protection;

- equipped with temperature sensors;

- three-level frost protection;

- automatic heating time control;

- pressure protection;

- control over lack of traction.

Important! It is worth paying attention to the possibility of quality service unit in that geographical area, where the gas boiler goes to work.

Wall-mounted or floor-mounted, single-circuit or double-circuit, with one or two heat exchangers, automatic or manually controlled – selection criteria gas technology enough. The main thing is that savings do not stand in the way of safety.

Advantages:

- Heat exchanger made of high quality copper;

- Modulated gas burner made of stainless steel;

- Brass hydraulic block;

- Good security system.

Manufacturers of gas equipment offer two types of heating devices - wall-mounted and floor-mounted. The most widespread use today is for wall-mounted gas boilers, because they have a number of undeniable advantages, among which we can highlight: payment for actually consumed energy, independence from the use of hot water, the ability to independently determine the temperature regime in the heating network, as well as the beginning and end of the heating season.

In this article:

Types of mounted boilers

Single-circuit - used exclusively for space heating.

These are the simplest boilers in terms of design characteristics.

Double-circuit – for water heating and heating.

The structure of a double-circuit gas boiler is more complex design made of copper tubes (through which the coolant flows) and metal (steel) plates, which increase the heat capacity of the boiler.

This design of the heat exchanger is called primary. The main task of the system is to transfer energy to the burner, which contains the coolant.

Double-circuit boiler design

The secondary heat exchanger (plate) of a gas boiler is designed to heat water in the water supply system. Heating occurs due to the transfer of thermal energy from the coolant to the water in the water supply system. Detailed description.

Condensing - have the most complex device in terms of design parameters.

The boilers have a system with a closed combustion chamber, in which a fan with variable speed creates an optimal gas-air environment. Combustion products are not completely released into the atmosphere - they partially condense the steam in the smoke mixture and reuse it.

Such a system is very economical, which significantly reduces gas costs, which can be reduced by.

Additional benefits

In addition to the above, mounted boilers heating have a number of significant additional advantages:

Universal design and dimensions of the boiler

- Compact dimensions– this significantly reduces the space used in the room. As a result, wall-mounted boilers can be used everywhere (in houses, apartments in multi-storey buildings, in the country).

- Power ranges from 10 kW to 40 kW. Heating 10 square meters of area requires 1 kilowatt of power. Accordingly, one boiler can heat up to 400 square meters.

- Affordable price– wall-mounted boilers are 1.5-2.5 times cheaper than floor-mounted ones.

- Silence– they can be installed in any room (silence is achieved due to the existing hydraulic system).

- Economical– low gas consumption.

Brief description

For gas boilers, there are two types of ignition - electronic and piezo ignition.

The most optimal and economical is electronic ignition. It runs automatically as needed. If the gas supply is stopped, the boiler goes out, and when the gas supply is resumed, it restores its operation.

Piece ignition starts the device by pressing a button. Accordingly, about automatic operation You can forget the boiler (you will have to turn it on yourself).

Most models are equipped various devices security.

These include the following devices and technical solutions:

- flame presence sensor – when the flame dies out, the gas supply stops;

- device for blocking the operation of the boiler during a power outage;

- sensor for blocking the boiler operation in case of temperature rises above the norm;

- a device that blocks the operation of the boiler if the gas volume or pressure is below normal.

Boilers can also be divided according to the type of exhaust mixture emission:

- boilers with natural draft (open combustion chamber);

- forced draft boilers (closed combustion chamber).

Coaxial chimney with horizontal outlet

On devices with natural draft, a collector must be installed to remove combustion products.

The principle of a coaxial chimney lies in the fact that the air inside the room is not “eaten up” by the boiler. And thanks to the fan built into the boiler, waste products are ejected and fresh air from the street.

Double-circuit boilers have differences in the hot water supply system.

Some have a capacity (boiler) of the displacement characteristic of the model. This system is used when increased consumption hot water over 15 l/s. If you consume less than 15 l/s, then you should choose a boiler with a flow-through type of water heating.

Manufacturers rating

The undoubted leading countries in the production of boilers and gas equipment are Germany and Italy.

Such famous brands, like Bosch, Vaillant, Beretta, Ariston are breaking all sales records all over the world. Boilers from these manufacturers are represented by a wide range of models and modifications. Products are made from quality materials, has nice design, light weight and increased level security. Consumer reviews show that the boilers of the listed companies have a long service life.

Comparison table of the most popular models

| Model | Number of circuits / combustion chamber type | Power/efficiency | Price |

|---|---|---|---|

| Bosch ZW 24-2 DH AE | 2 / closed | 23.6kW / 92.3% | RUR 26,630 |

| Ariston BS II 24 FF | 2 / closed | 24.2kW / 93.0% | RUR 35,760 |

| Beretta CITY 24 RSI | 1 / closed | 23.9 kW / 91.8% | RUB 37,050 |

| 1 / open | 24.0kW / 91.0% | RUR 40,490 | |

| Buderus Logamax Plus GB162-65 (condensing) | 1 / closed | 62.0kW / 110% | RUB 161,000 |

Functional features of each model

Bosch ZW 24-2 DH AE - German quality

Bosch ZW 24-2 DH AE

Electronic ignition, automatic power control in heating and hot water preparation mode, three-speed circular pump, autodiagnostics, fault indication, built-in traction control and overheating protection, can be adjusted to liquefied gas.

Ariston BS II 24 FF

Operates at reduced gas pressure (up to 5 mbar), is resistant to voltage surges, built-in condensate collector, extremely strong and durable burner and heat exchanger materials. Built-in function of protection against freezing, scale formation, blocking of a three-way valve and a circular pump, and a self-diagnosis function.

Beretta CITY 24 RSI

It is possible to convert the boiler to liquefied gas. There is a built-in gas pressure stabilizer, a microprocessor board that controls inputs, outputs and alarms.

Automatic bypass of the heating circuit, smoke removal pressure switch, which monitors the operation of the fan and smoke removal system. Anti-jamming protection function for the circulation pump, which is activated automatically every 24 hours after the last pump cycle.

Vaillant atmoTEC Plus VU INT 240-5-H

It is possible to convert to liquefied gas; Frost protection, anti-jamming protection for the circulation pump and three-way valve are installed. Automatic troubleshooting with subsequent display of information on the display.

Option “Winter/Summer”, it is possible to use the boiler in low-temperature systems.

Buderus Logamax Plus is our choice!

The ETA plus system is designed to optimize energy use and minimize overall operating costs.

ETA plus consists of a burner with modulated combustion control in the power range of 15 - 100%, a highly efficient heat exchanger for year-round condensation mode, a modulated circulation pump UPER 28-80 with capacity control (on special order).

The model has the ability to operate without maintaining a minimum volume flow.

The FLOW plus system ensures maximum utilization of the condensation heat of flue gases and low noise operation thanks to two components:

- a simple hydraulic circuit without a bypass valve, because no minimum volume flow required;

- circulation pump with adjustable capacity, which ensures maximum use of the heat of condensation of flue gases.

Which one to choose? Expert's conclusion

From the models given in the table, a comparative assessment can be made as follows:

- The most optimal and multifunctional are double-circuit gas boilers.

- Within the cost of a double-circuit boiler, you can purchase a single-circuit boiler, the functionality of which is inferior to the first only in the heating capabilities of the device.

The most advanced and productive are condensing boilers. This type of boiler is very economical, with high level Efficiency True, they are much more expensive, and they also require certain conditions to operate all the functionality included in them.

You should immediately decide for what purposes you are going to purchase a wall-mounted gas boiler: only for heating the room, or do you want it to additionally heat water.

The most acceptable in terms of price-quality ratio are double-circuit boilers.

Along with other types of boilers, they are equipped with more extensive functions and safety sensors.

Buy a boiler with a closed combustion chamber and electronic ignition. The secondary heat exchanger must be of a separate type. These characteristics will significantly save gas consumption, extend the life of the boiler and, as a result, save your money.

Such equipment is quite durable and safe. To help in choosing the best option for heating equipment, a rating of gas boilers was compiled, which were especially popular in Europe and among our compatriots in the first half of this year.

Top five leaders in the production of gas heating equipment

The vast majority of heating gas equipment is represented on the domestic market for climate control equipment by European manufacturers, as well as some representatives of the Asia-Pacific Economic Community. Among the most popular in our country are manufacturers of gas boilers from Germany, Italy, the Czech Republic, Slovakia and South Korea.

The first place in the popularity ranking is shared by German gas boilers produced by the Vaillant Group concern and the Wolf company. The German brand Buderus shares second place among the most popular manufacturers with the German holding Viessmann, and third place was taken by the Slovak concern Protherm and the Italian company Baxi.

Comparison technical characteristics and the functionality of the products of these companies is quite difficult, since in many ways they are very similar to each other.

Review of products from leading brands

This review should begin with gas boilers, which took first place in the popularity rating not only among our compatriots, but also among European consumers. These are products of such German giants as Vaillant Group and Wolf.

Boiler equipment from Vaillant Group

Vaillant Group is a recognized leader in the production of heating gas boilers. On the domestic market, Vaillant Group is represented by almost all possible modifications of heating equipment:

- Line of wall-mounted boilers. atmo TEC series with an open fuel chamber, turbo TEC series with a closed fuel combustion chamber.

- Line of floor-standing boilers. The iro VIT series is equipped with an electronic security and self-diagnosis system, the avto VIT series is fully automated devices.

Single-circuit boiler units are designated by the letter index VU. A special feature of these heating devices is that almost all models are equipped with circulation pumps.

Double-circuit heating systems are designated by the letter VUW. In addition, boilers of this brand are produced in both standard (PRO) and modernized (PLUS) versions. The rated power of Vaillant boiler units varies depending on the model from 12 to 36 kW.

Heating equipment from Wolf

The company's products have been repeatedly awarded with certificates confirming their environmental friendliness and safety. On the domestic market, brand heating boilers are represented by:

- A line of floor heating units. The FNG series can operate on both natural and liquefied gas, the CHK series has an exclusive design.

- A line of wall-mounted boilers. The CGG series are double-circuit boilers, they can be either with an open or closed fuel chamber, the CGU series are single-circuit boilers with simple controls.

- Condensing boilers of the MGK line.

Boilers for individual heating from Viessmann

The Viessmann concern's model range of heating devices is represented by the Vitopend line, which includes floor- and wall-mounted devices, with a closed and open fuel chamber. The performance of the units varies depending on the model and can be:

- for wall-mounted boilers from 10.5 to 31 kW;

- For floor installations up to 140 kW.

The main feature of devices from this manufacturer is that the boiler does not turn off the heat exchanger when consuming hot water, but simply increases productivity.

Heating equipment from Buderus

The products of this German manufacturer have become famous among our compatriots for their compactness and design features.

The line of wall-mounted devices is represented by a series of Logamax double-circuit boilers and Logamax plus condensing equipment. The floor line includes the Logano series, which is a bestseller for the first half of this year.

Protherm products

Gas boilers from this manufacturer are widely represented in Russia and occupy a strong position in the markets Eastern Europe. The most popular models include:

- a line of wall-mounted double-circuit heating systems of the Pantera series, which is perfect for heating and hot water supply of small private houses, cottages and individual apartments;

- the Cheetah series, characterized by an ideal price-quality ratio;

- the Lynx modification is a wall-mounted device for individual heating;

- Leopard boiler models adapted to work in gas mains with low pressure levels;

- the Bear line of floor-standing boilers, which are distinguished by their unpretentiousness, high performance and ease of control.

Boiler equipment "Baxi"

You can start your review of heating devices from the Italian company Baxi with their line of wall-mounted units:

- MAIN FOUR series, represented by two dual-circuit models with a power of 24 kW with an open and closed combustion chamber;

- there are 6 models in the Fourtech line, including 4 single-circuit and only two double-circuit models with different combustion chamber designs, power from 14 to 24 kW;

- the Ecofour modification differs from Fourtech only in components, the number of models, design and power are identical;

- the Luna 3 Comfort boiler series has 6 models, including an equal number of single- and double-circuit boilers with different types of combustion chamber, power from 24 to 31 kW;

- The Luna 3 Comfort Air series model range is represented by two turbocharged boilers with a capacity of 24 - 31 kW;

- the Luna 3 Avant series differs from previous models by the presence of an additional condensation heat exchanger, the power of the devices is 24 - 31 kW;

- SLIM is a line of floor-standing single-circuit boilers with an open combustion chamber, represented by 11 models with productivity from 15 to 116 kW.

The best gas boiler

A comparison of gas boiler equipment was carried out according to the following characteristics: design (wall-mounted, floor-mounted), functionality (number of circuits), gas combustion chamber (open, closed), gas consumption, m3/h, average cost.

In the nomination for the best floor-standing heating boiler, Baxi Slim 2300Fi received more votes. Double-circuit, with a closed combustion chamber. The power of the device is 29.7 kW with a gas flow of 3.49 m3/h. The average cost is 44 thousand rubles.

Advantages of the device: built-in 50 liter water heating tank, electronic indication and piezo ignition, multi-level security and self-diagnosis system.

The main disadvantage of the device is its high cost.

The Baxi Luna 3 comfort 240 Fi received the palm in the category for the best wall-mounted heating boiler. This is a dual-circuit device with a closed combustion chamber, with a power of 25 kW. Gas consumption at this performance is 2.84 m3/h. Cost 25 thousand rubles.

Main advantages: full adaptation to the peculiarities of the domestic gas supply, the ability to program for 7 days, a diagnostic system and multi-level protection, the presence of authorized service centers.

Disadvantages of the device: relatively high cost and sensitivity of the electronics to changes in mains voltage.