Solid fuel boiler Cooper

Thus, a standard Cooper heating boiler includes several working systems at once.

The basic system is considered to be a liquid heating system due to the combustion of solid fuel in a chamber. The boiler chamber is made according to special technology. In it, air flows are pumped in such a way as to create the so-called “smooth combustion” process.

Air is supplied to the burning fuel in sufficient quantity to keep the combustion process at the point of maximum efficiency. This means that the fuel will burn with the release of the maximum permissible amount of heat, but will not burn out too quickly.

That is why the Cooper heating boiler is often called a boiler long burning. Unlike a potbelly stove or stove, which previously had to be loaded almost every hour, solid fuel boilers long-burning Coopers need loading much less often. Advanced models, for example, the Cooper OK 30 heating boiler, are equipped with special automatic fans.

2 Review of Cooper heating boilers with high efficiency - video

Their task is to force air into the combustion process. Moreover, the fan starts pointwise, turning on at the command of the thermal sensors that are installed inside the chamber.

Reviews of the Cooper heating boiler also indicate that the fuel combustion process in it has been significantly improved due to the presence of sensors, blowers and the design of the chamber itself.

However, this is far from the only improvement within the described equipment. Thus, the Cooper heating boiler is equipped with an improved heat exchanger made of special metal alloys.

The heat exchanger has a serious impact on how well the energy from burning wood or coal is transferred to the heat carrier.

The presence of a heat exchanger allows not only to increase energy transfer, but also to control the heating level of the KUPER boiler.

A serious disadvantage of conventional ones for the entire time of their existence was that it was quite problematic to regulate their heating level.

A person has to play around with the amount of fuel supplied, and it’s not a fact that this will immediately give results. In addition, it was also very difficult to interrupt the operation of the unit immediately.

But the Teplodar Cooper solid fuel boiler was designed during development in such a way as to eliminate all these shortcomings.

Heating boiler Cooper OK 15 and its more modern models are equipped with very precise regulators operating temperature. You can lower or increase the heating power in the range from 30% to 100%. In addition, if necessary, you can limit the access of oxygen to the combustion chamber, which will allow you to quickly extinguish the firewood and short time shut down the entire system.

As you can see, basic principle The operation of the boiler is quite simple and straightforward. When fuel burns, a fairly impressive amount of energy is released.

The following is used as fuel:

- Wood;

- Peat;

- Coal;

- Modern solid fuel samples.

The fuel burns smoothly and emits maximum amount energy, while an improved chamber, an air injection system and a sophisticated heat exchange system allows it to produce amazing high efficiency with a minimum of labor costs.

In the same time modern system power regulation eliminates the last serious drawback of ancient potbelly stoves by installing boilers heating Cooper 1st, as competitors for gas heating equipment.

But the details described above are far from the only advantages of solid fuel boilers.

For example, the solid fuel boiler Cooper OK 20 and other models are equipped with an ash remover. This is a fairly simple device that gives a person the opportunity to clean the chamber from excess combustion products without wasting time blocking the operation of the boiler itself.

That is, ash and ash can be removed from the boiler directly during its operation, without any fear.

Some models also have additional systems whose task is to maintain the temperature inside the heating circuit in case the fuel runs out.

This kind of semi-automatic improvement is of great importance for the quality of operation. After all, now the boiler does not have to be constantly monitored and loaded. If the temperature drops, the automation will simply start the heating element or gas burner electrically, thus stabilizing the temperature level in the heated room.

Tips for choosing

The choice of KUPER solid fuel boilers should be taken seriously. Indeed, unlike conventional gas heating devices, solid fuel boilers are highly dependent on their own design and the engineering solutions taken.

In addition, you should determine in advance what place it will occupy in your heating system.

They are used as systems:

- Basic or basic;

- Additional or emergency.

For example, if the boiler is intended as a kind of emergency equipment, that is, it will work additionally in the event of a breakdown of the main heating devices, then there is no point in purchasing expensive solutions. It is enough to choose a solid fuel boiler Cooper OK 15 or a heating boiler Cooper OK 20. They have relatively low price And good performance productivity.

If you are going to use it as the main source of heating, then it’s worth taking a closer look at more advanced and powerful models. The solid fuel boiler Cooper OK 30 will perform well.

Again, remember all the nuances. Not every sample has an automatic temperature maintenance system added, and it’s worth noting that with its inclusion, the price of Cooper solid fuel boilers increases. But the presence of a backup electric heating element or gas burner guarantees you that the equipment will be able to operate even after the fuel reserves in the chamber are completely depleted, which is very convenient.

Also take a closer look at the quality of materials, camera design and many other things. They all matter and influence the final result. In particular, on the efficiency of the boiler.

The Kupper OK series stands for heating boiler, and not the American “Ok” from shortened slang expression Okay, as many might think. Boiler Kupper OKa universal single-circuit unit, capable of working on fuels such as coal or firewood. The device is used in heating residential and industrial facilities ranging in size from 80 to 200 m2.

If necessary, the Kupper OK boiler, in addition to using the main type of fuel, can be transferred to automated operation by reconfiguring it to the process of obtaining thermal energy from the combustion of gas or pellets using burners manufactured at the Teplodar enterprise. It is especially pleasing that the reconstruction is carried out without additional plumbing and welding work, which significantly saves money.

When equipping boilers Kupper OK automatic system for power regulation, a combustion regulator with a control panel can be installed on them, which is connected to the auxiliary unit of heating elements. Expanding the range, the Novosibirsk company Teplodar offers models for rooms up to 180 m2, equipped with a convenient cast-iron hob with the abbreviation in the name Cooper OVK.

Installation diagram with pump

Our review is devoted to solid fuel equipment from the Siberian company Teplodar. We invite you to familiarize yourself with the main characteristics, structure and operating principles of the Kupper OK heating boiler. The instruction manual and customer reviews will help us with this. The plant produces three main modifications, with the same design and internal elements. The main differences are in the nature of power characteristics:

- Kupper OK 9 boiler - used for heating small volumes not exceeding a heated space of 90 m²

- The Kupper OK 15 boiler is medium in size and can be placed in premises for various purposes with an area of up to 150 m².

- The Kupper OK 20 boiler is the largest in the series and can be used in any heating system of a construction site up to 200 m² in size.

Features of the Kupper OK boiler

- Manufacturers, in the Kupper OK series, in addition to standard water jacket, a design was proposed insingle-tube heat exchanger, which increased efficiency and was able to improve thermal removal.

- The heat exchanger pipe system was placed in checkerboard pattern. We equipped the unit with a removable plate, which acts as a flame arrester, with its help we increased the flame stroke and were able to completely extinguish the high flame in the boiler. Thus, it was possible to prolong combustion and significantly increase the efficiency of the boiler.

- By means of a specially placed automatic traction regulator, it is possible to set the power of the device within a range from 30 to 100%.

- As the solid fuel burns out, a built-in 6 kW heating element unit is put into operation. Such support delays the cooling of the coolant temperature in the system circuit, and under certain conditions can work for heating during periods that are not very frosty.

- The device is equipped with accessories that allow you to clean the firebox. In addition, the kit includes a rotary gate and a thermal thermometer for monitoring temperature regime boiler

Boiler Cooper HVAC

Since you and I are talking about creating an independent heating system, and this is precisely the opportunity that solid fuel equipment provides us with, then why don’t we expand the possibilities? This is probably how the engineers of the Teplodar company reasoned and designed the Kupper OVK universal boiler. Today we can find two models:

- Cooper OVK 10 boiler with the ability to heat 100 m2 of space, and equipped with a stove with cast iron rings;

- The Kupper OVK 18 boiler is used in any heating systems with an area of up to 180 m². Equipped with a full cast iron stove, expanding functionality and increasing comfort.

If there is no possibility of connecting to citywide communications, the unit allows not only to heat rooms up to 180 m2, but also provides the ability to cook food on a cast iron hob. All the features of Kupper boilers described above are applicable to HVAC modifications, including conversion to gas equipment.

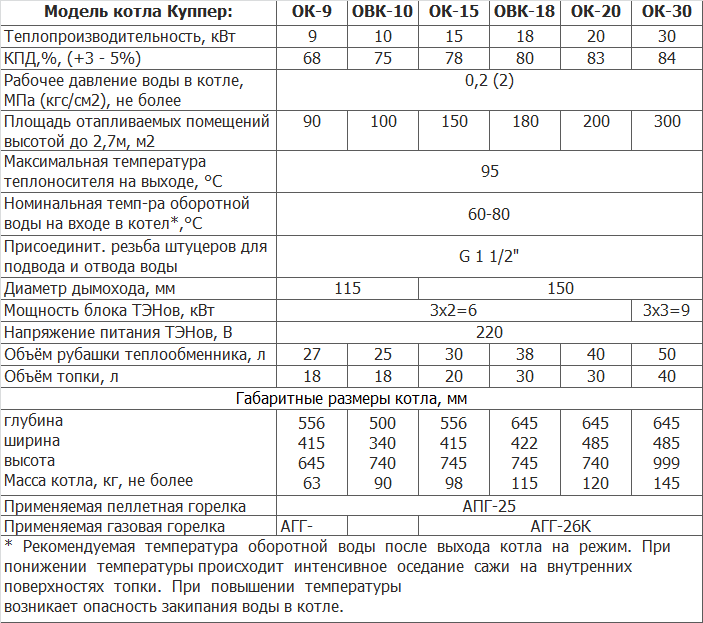

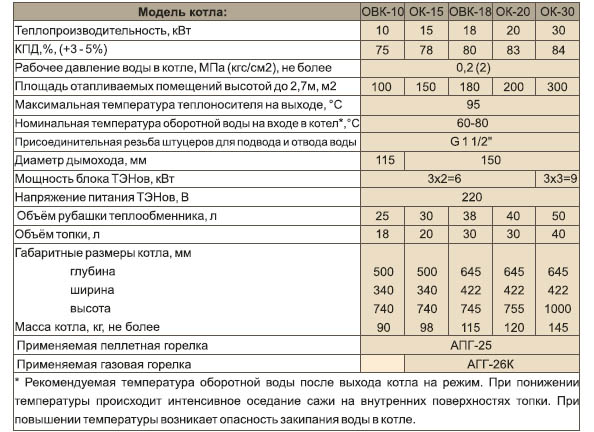

Boiler Kupper OK technical characteristics

Two connecting fittings are located on the side of the Kupper OK unit. The first one is mounted on top and serves as a connecting pipe for supplying coolant. The second is located at the bottom, which allows you to build a balanced gravity system and ensure high-quality return flow. The geometry of the fittings helps to connect the device to the heating circuit from any side.

Principle of operation

Having opened the loading door, the owner places a solid fuel resource in the form of firewood, coal stone or peat briquettes, after which the door closes. Having opened the door of the lower chamber, we make kindling. The combustion process is accompanied copious discharge thermal energy that heats the coolant in the tubular heat exchanger and additionally in the “water jacket”

Staggered arrangement of tubular heat exchanger

Staggered arrangement of tubular heat exchanger Heated the coolant begins to move under the pressure of natural gravity, or through, which is better installed on the return pipe. The resulting flue gases are discharged through a smoke pipe with a diameter of 150 mm and a rotary damper into an atmospheric chimney. The Cupper OVK 10 boiler series has a smoke pipe size of 120 mm.

The thermal insulation material is basalt wool located inside the side walls of the boiler. Decorative cladding panels Kupper OK additionally retain heat and prevent burns from contact with external elements of the device.Thermal insulation modern, non-flammable material helps achieve increased efficiency.

Boiler thermostat Kupper KO

Boiler thermostat Kupper KO Using the flap, which is attached to the ignition door, you can regulate the intensity of the flame. The power adjustment range is from 30% to 100%. You can configure it like this: manual method, and with the help of automation. The automatic method is possible after attaching the draft regulator (not supplied as standard and must be purchased separately). The regulator is mounted on the Cooper OK on the left side of the boiler using a G3/4″ fitting.

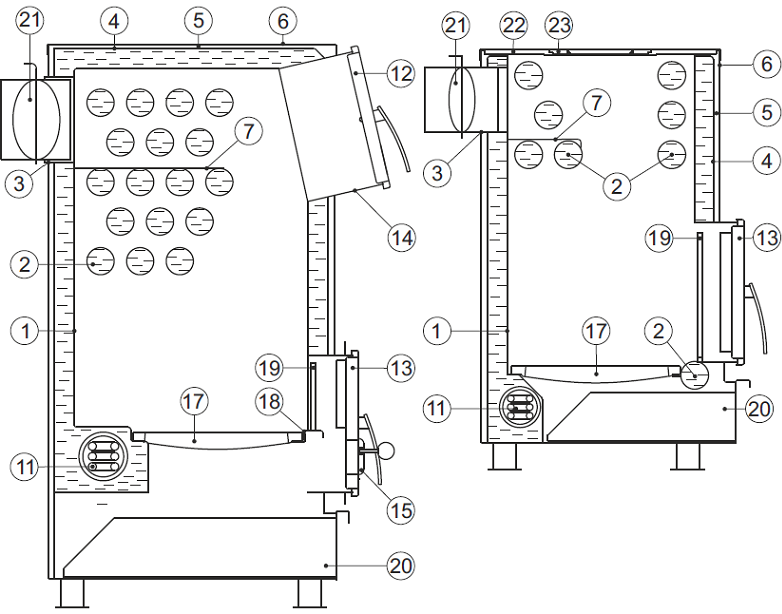

Cooper KO device

Schematic arrangement of the main elements with detailed description we show in the figure below:

- Combustion chamber;

- Tubular heat exchanger;

- Smoke exhaust hole;

- Encircling water jacket;

- basalt fiber;

- Decorative casing;

- Flame-fighting visor;

- Supply pipe;

- Return pipe;

- Plug - adapter;

- Threaded heating element block;

- Loading door;

- Lapel flap;

- Automatic traction control;

- Grate;

- Grate support stand;

- Damper flap;

- Ash collection box;

- The damper in the chimney is rotating;

- Cast Iron HVAC Cooktop;

- Cast iron ring.

Cooper OK technical specifications

Despite the fact that today the Teplodar company does not release the Cooper OK 30 boiler model, we nevertheless included it in the list with technical characteristics; perhaps the device is still on sale, or the plant will continue to produce them in the near future.

You can choose a boiler according to the well-known rule: 1 kW heats 10 m2, but since modern construction constantly offers new methods of home insulation, and plastic heat-saving windows are installed everywhere, then perhaps 0.7 kW will be enough for 10 m2. As it were, right choice boiler is of primary importance when designing a heating system.

Do not neglect advice and adequate consultation from a qualified expert. You will select the optimal model depending on the size of the heated room, the design nuances of the facility, the type of heating system, fuel resources and coolant, the number and types of radiators, as well as other parameters of the structure.

Boiler Kupper OK Fuel types

Units of the "Kupper" series are operated on durum varieties fuel resources. To ensure maximum efficient operation of the boiler, the manufacturer recommends using fuel material with the following characteristics:

- Firewood: cross-section from 40 to 100 mm, length depends on the Cooper OK model and ranges from 300 to 500 mm, humidity should not exceed 20%. The intensity of combustion affects the duration of operation of the unit from one load of firewood, and on average lasts from 30 to 90 minutes.

- Coal: The grain size of coal stone should not be less than 40mm. Depending on the intensity of combustion, the duration of operation can reach 8 hours.

- Peat briquettes: the mass fraction of ash should not exceed 16%, humidity should not exceed 18%, the duration of operation from one stack of briquettes depends on the saturation of the flame and can vary in the range from 6 to 10 hours.

The room where the Cooper OK boiler is located must be separate from human habitation. The boiler room must be equipped with an individual chimney and create ventilation capable of supporting three times air exchange in a period of 60 minutes, taking into account the need for air mass for the combustion process.

Possible malfunctions and their elimination

We found it for you possible malfunctions boiler Kupper OK, we have collected them in one table and give recommendations from the manufacturer to eliminate the causes of breakdowns. If you encounter more complex difficulties, you need to contact the service center that services your purchase.

Boiler Kupper OK advantages

- Excellent value for money and quality workmanship. Increased attention manufacturing plant to the design and wide range of products, allowed the Teplodar company to take a leading position in the market in Russia, the products enjoy deserved success in Belarus, Ukraine, Kazakhstan, Kyrgyzstan;

- Good reviews from product buyers are the result of the technically competent approach of the plant employees to the production process;

- Scrupulous selection of suppliers and continuous attention to the needs of homeowners are the basis of the company's policy. A balanced pricing policy allows us to offer consumers optimal quality at a reasonable price;

- The box in which waste ash accumulates is serviced with the ignition door closed;

- The universal Kupper Ok makes it possible to use fuel resources in the form of firewood, coal, electricity, and during restructuring - gas and pellets;

- The price is not inferior to quality, the cost of Cooper OK starts from 20,000 rubles;

- Cooper HVAC models are equipped with a cooking range;

- Eye-catching design and bright colors attract attention;

- Excellent thermal insulation with basalt wool.

Minuses

Certain disadvantages, according to consumer reviews, is the fact that commissioning and service maintenance unit and everything structural elements, as well as the first start-up of the equipment into working condition is carried out by qualified employees, with special permission from the manufacturer to service devices of this type.

Although we do not consider this a significant disadvantage, since ultimately, these activities affect your safety. Please note that routine maintenance on the launch of the Kupper OK unit, are accompanied by filling out documents by the sales, installation and maintenance structure. These documents will be required if a warranty claim is discovered. You can also add that:

- The series is new and has not been tested for decades;

- The Kupper OK heat exchanger is made of steel, which makes it less durable than cast iron;

- The thermal regulator for the boiler and the control panel for the heating element unit are not included in the basic package;

- Absence dual circuit options are expected to be used, which will lead to additional costs.

Rating 5

Comment: Great boiler! When I bought it, I liked that you can heat it with anything (I heat it myself with coal and wood). Quickly heats the room, the boiler power is adjustable. In general, I recommend it.

25/05/2012

Rating 5

Comment: "KUPPER" is a universal heating boiler that can operate on any type of solid fuel. These include firewood, euro-firewood, briquettes, roofs, pellets, wood chips, wood waste, peat, coal. At the same time, pellets, briquettes and roofs can be made from straw, husks, grain processing waste and other types of plant origin (more than 50 options in total). The boiler can use firewood for ignition (horizontally) up to 40 cm, for combustion (vertically) up to 50 cm. The most economical option The operation of the KUPPER boiler is as follows: ignite using firewood (horizontal stacking), and load the main fuel coal through the upper loading channel. With this option, the longest and maximum heat transfer mode is achieved.

07/08/2012

Score 4

Comment: Hello everyone. I want to write a little about the Cooper Ok 30 boiler. I use it

with this boiler since September 2012. I bought it because

no gas. And there was no finance to buy an expensive imported boiler. Boiler

I like. There are built-in electric heating elements 3 pcs x 3 kW. When

I purchased a boiler, I also bought a draft regulator and bought a control unit

tenami. The total cost of the boiler was about 32,000 rubles. At first

heated it with wood. the conclusions are that the firebox needs a small size

The firewood for this boiler is 35-40 cm, if you can’t throw in a lot of longer wood (although it’s possible if you want). IN

this moment switched to briquettes. First time I bought Pinkey briquettes, thing

good, burns great, but a little expensive. then I decided to try roof briquettes

they are cheaper. I was completely satisfied with loading briquettes into

Cooper boiler. The heated area of the house is 190 sq. m. When on the street around -

20 -25 degrees I burn a 20 kg briquette in a 10 kg package then leave it for

night on the tens. So, in principle, the Cooper boiler is in its price category

excellent boiler. So far nothing has fallen off during use.

Disadvantages 2: it is a small firebox and it is not convenient to clean the water heating pipes.

The draft regulator and shadow control unit work perfectly. I tried to heat with pellets, but it’s not an option; forced air is desirable (a fan as is customary for pellet boilers), but in principle I threw it at night, they flare up and begin to smolder. I really liked the convenience of heating with briquettes. From pellet boilers of the KP type (manufactured in Novosibirsk, I’m not delighted with the heap). a lot. If the heating system is done correctly, the Cooper boiler works perfectly. I have a 2-pipe forced circulation heating system in a 2nd floor house.

- Design Features

- Kinds, specifications and reviews

- Installation and connection

In pursuit of versatility, many manufacturers producing heating equipment produce devices that can switch from one type of fuel to another if necessary. The Teplodar company was no exception, releasing the Kupper universal boiler, capable of switching from coal and wood to gas or pellets in the blink of an eye. Our review today is devoted to a detailed analysis of this model and its varieties.

The Teplodar company has been on the heating equipment market for almost 20 years. During this time, we have gained extensive experience in creating inexpensive, efficient and reliable equipment. At the moment, its product range includes more than 100 models of various heating devices, which are among the leaders in the Russian market.

The Cooper solid fuel boiler wins customers not only with its versatility, but also attractive design, which is quite a rare occurrence for the domestic market. Let's take a closer look at it and analyze its distinctive features.

Design Features

The Cooper heating boiler has a steel body, inside of which there are fire chambers and an ash pan, surrounded by a water jacket. To increase the efficiency of heat removal, in the upper part of the boiler, right and left-hand side The heat exchanger is connected by transverse pipes arranged in a checkerboard pattern. The combustion chamber space is separated from the pipes by a steel hood. Flue gases do not move directly to the chimney, but go around this obstacle, transferring even more energy to the coolant and increasing the efficiency of the boiler. To reduce heat loss, the body is covered with insulating basalt cardboard, on top of which the body panels are located.

Photo 1: Design of a solid fuel boiler from Teplodar “Kupper” OK

"Cooper" can be used in . For easy connection to the supply and return lines, nozzles are located on the right and left walls of the boiler, at the top and bottom.

Attention! It is recommended to connect only to the pipes on one side. When the supply and return are connected to different sides of the boiler, the efficiency of heat exchange in the water circuit decreases.

To regulate the combustion intensity, a damper is located in the lower part of the housing. By opening or closing it, you can regulate the air supply to the firebox. This can be done manually, or you can install an automatic traction control. It measures the temperature in the heat exchanger and, in accordance with the set values, adjusts the damper opening value. This process occurs mechanically and does not require power.

The Cooper domestic boiler can maintain a constant temperature in the system between coal or firewood loads using electricity. For these purposes, each device has built-in heating elements with a power of 6-9 kW.

Return to contentsTypes, technical characteristics and reviews

The Teplodar company produces several types of “Kupper” solid fuel boilers. Let's look at each of them separately and analyze the features and technical characteristics of each of them.

Boilers "Cooper" OK 15, 20, 30 on wood and coal

"Kupper" OK are classic solid fuel boilers. A total of three standard sizes are available with a power of 15, 20 and 30 kW. They are capable of heating rooms with an area of 150 to 300 m²

Photo 2: Solid fuel heating boiler “Kupper”

Photo 2: Solid fuel heating boiler “Kupper” Below is a table with their technical characteristics:

A short review from the owner:

I spent a long time choosing and eventually decided to buy a Cooper OK 20 boiler for my Vacation home, which has not yet been completed. Heating system with metal-polymer pipes and aluminum radiators. The heated floor is supplied by a separate circuit. For an area of 120 square meters Over the winter, about 3 tons of coal and about 4 cubic meters of firewood were consumed. Taking into account the inertia of the solid fuel combustion process, I installed a hydraulic separator.

Arkady Ivanovich, Voronezh

Kupper boilers are capable of operating on gas or fuel pellets when the appropriate burners are installed on them, which are also produced by the Teplodar plant.

Cooper boilers with hob

This series is a modification of the previous one and consists of only two devices for 10 and 18 kW. main feature– this is the presence of a cast iron hob. Not only can you heat your home, but you can also cook food on the stove.

Photo 3: Cooper boiler from Teplodar with hob

Photo 3: Cooper boiler from Teplodar with hob Main parameters of the models:

Here's what users on the forums say about this modification:

We use a Cooper OVK-18 boiler to heat a two-story production premises. The heating system has 10 radiators on both floors and a heat accumulator. We heat it with briquettes made from spruce sawdust. For a day, 2 packages are enough for 60 rubles each. We tried to heat it with coal, the consumption was 1.5-2 buckets per knock at a price of 30 kg bag of 220 rubles. During severe frosts They connected heating elements and then only 2 kW out of 6.

Elena Vladimirovna, Ekaterinburg

The OVK series is also ideal for installation in small country houses.

Pellet boiler "Cooper"

It is a boiler of the OK or OVK series with an installed APG-25 pellet burner and a hopper with a control unit. For the operation of equipment for burning fuel pellets, a power supply is required. It can be installed without any modifications directly on an existing boiler connected to the heating system.

Photo 4: Automatic pellet boiler “Cooper” with APG-25 burner

Photo 4: Automatic pellet boiler “Cooper” with APG-25 burner Below is Comparative characteristics Cooper boilers with pellet burner:

Feedback on the operation of the Kupper boiler using fuel pellets:

I connected the APG-25 pellet burner to the OVK-18 boiler. The settings are simple, everything is simple and clear. Electricity consumption is 2 kW per day, consumption of white pellets is 4 kg/hour. The system works without failures, the granules do not get stuck. The only negative is that the fan is quite noisy, you will have to replace it.

Vladislav Borisovich, Krasnodar

If your home already has an OK or HVAC series device installed and there is a reliable pellet supplier, then you can safely purchase and install pellet equipment from Teplodar.

Gas boiler "Kupper"

Conversion of the boiler from solid fuel to gas is carried out by installing a gas burner AGG-13K or AGG-26K. OK and HVAC boilers are suitable for these purposes, even if they are already installed and previously operated on wood or coal.

Photo 5: Cooper gas boiler with AGG-26K burner

Photo 5: Cooper gas boiler with AGG-26K burner Cost of boilers with different types burners:

Attention! Installation and connection of equipment for gas operation must be carried out by certified specialists, and the device itself is subject to registration.

Long burning boiler "Cooper" Pro

This model is new for 2015. The boiler can operate longer on wood thanks to new technical solutions. In addition to the water jacket and pipes inside the firebox, a water-tube grate is implemented. It allows you to remove heat from burning fuel even more efficiently. In addition, the secondary air supply has been modernized. The combustion duration on one load for Kupper Pro boilers is up to 8 hours. As with other models, it is possible to install a pellet or gas burner.

Photo 6: “Kupper” boiler about long burning from Teplodar

Photo 6: “Kupper” boiler about long burning from Teplodar Specifications:

Inexpensive low-power wood-burning boiler "Cooper" Comfort

The Comfort model is designed for heating small rooms and is available in only one standard size with a power of 10 kW. The boiler is designed to work with wood and has an enlarged firebox, allowing you to burn long logs. The original shape of the boiler allows the coolant to circulate freely inside the heat exchanger, eliminating the formation of stagnation zones. For ease of maintenance, it is equipped with a spacious ash drawer.

Photo 7: Wood-burning low-power boiler for the home “Cooper” Comfort

Photo 7: Wood-burning low-power boiler for the home “Cooper” Comfort Main characteristics of this model:

On Uyut boilers, as well as on all other Teplodar solid fuel heating boilers, it is possible to install equipment for operating on gas or fuel pellets.

As you can see, Teplodar offers heating boilers for every taste, the efficiency and safety of which is largely determined by the correct installation, connection and piping. Below we will look at the basic rules for installing Kupper solid fuel boilers.

Kupper series boilers offered on the market thermal equipment Novosibirsk manufacturer Teplodar, compare favorably with other models with their versatility. Positioned as solid fuel (firewood, coal, briquettes), they are also equipped with electric heating elements. This allows you to maintain the temperature of the coolant in the system after the main fuel burns out.

Also, any Kupper boiler, according to user reviews, provides electric autonomous heating. When installing special equipment it will operate on gas, diesel fuel or pellets. Another advantage of purchasing a boiler is high level security. External surfaces are thermally insulated with basalt cardboard and also lined with special panels. The latter combine decorative and protective functions.

The operating principle of all Kupper models is based on the transfer of thermal energy generated during the combustion process to the coolant of the heating system. High efficiency of heat exchange and heating of liquid in the boiler is achieved thanks to design feature water jacket devices. Also, there is a heat exchanger in the boiler firebox. In it, the pipes are staggered in several tiers. The water circuit is designed specifically to create a directed flow of liquid and eliminate stagnant zones.

To achieve maximum efficiency of thermal energy exchange, a visor is installed between the heat exchanger tubes. It also prevents flames from entering the smoke box. This part is removable, which makes it easier to clean the heat exchanger from soot. There is a rotary damper on the boiler firing door, which ensures the supply of air to the combustion chamber (when fully loaded long burning mode) and prevents burning coal from spilling out. Having considered the principle of operation of Kupper heating boilers, it is important to note their efficiency and thoughtful design.

Area of use

The main purpose of boilers is to provide efficient heating private dwellings (houses, cottages, dachas) with total area from 70 to 300 m2, in cold Russian winters. Positive reviews about the boiler from the Teplodar company indicate that such a unit can become the basis of a heating system with natural or forced circulation of coolant. In addition, Novosibirsk equipment is widely used for heating various utility rooms.

Some models of the Kupper series are equipped with a cast iron hob. It is convenient to both heat and cook food on it. It is installed instead of part of the upper water “jacket”. Moreover, the type of fuel used does not in any way affect the functionality of the surface.

Reviews

“I purchased a Cooper 18 OKW last fall. It worked perfectly during the winter, even at -20 °C it was warm in a house with an area of 70 m2. Hob It turned out to be superfluous - I don’t use it. He heated with wood and coal, and at night additionally used heating elements. There are two comments: I had to purchase a draft regulator; it’s better to allocate a separate room for the boiler room - it will be cleaner.”

Maxim, Voronezh.

“I have a pellet boiler manufactured by Teplodar OK 20 Kupper with a pellet burner for about 2 years now, it has been heating a house of 135 m2 and producing hot water through the boiler indirect heating. I took a more powerful one so that if necessary I could switch to firewood. I had to tinker with the settings. The auger bolt protruded strongly and the pellets got stuck. But after sanding everything works well.”

Ivan Gavrilov, Krasnoyarsk.

“I recently bought a Cooper OVK-18. The water in the system heated up to 60 °C in about an hour and a half. It’s warm in the house, although it’s only -2°C outside. You have to heat it twice, with wood. I want to try it with charcoal, I think it should be better. The big plus is that the walls of the boiler practically do not heat up - it’s not a big deal.”

Mikhail, Nizhny Novgorod.

“Our house is 8 by 8 m2, moderately insulated, and has a veranda with heated floors. The boiler was installed heating cupper OK-15 and additionally a draft regulator. On wood it easily accelerates to 90°C. They burned with briquettes (sawdust and peat). One bookmark is enough for 5-6 hours. There are no complaints about the boiler.”

Anton, Samara.

“I have a Cooper OK20. Circulation without a pump, natural. Radiators become hot within half an hour after lighting. 4 logs are enough for 3-4 hours. I haven’t connected the heating elements yet.”

Alexey Mityuk, Moscow.

“I have been using the Teplodar Kupper OK-30 boiler since the fall of 2012. Along with it, I bought a draft regulator and a heating element control unit. Heated area 190 m2. I immediately used firewood, but the loading chamber of the boiler was too small. I switched to Pinkey briquettes - a great thing, but a little expensive. I replaced it with Roof - cheaper and no worse. When it’s -20–22 °C outside, I burn 20 kg and leave it on heating elements overnight.”

Nikolay, Yekaterinburg.

Explanation of symbols

The Teplodar company offers to buy a solid fuel boiler Kupper in one of two versions: OK (heating) and OVK (heating and cooking). In addition, the units differ in power (from 10 to 30 kW), which is indicated in the name after letter designation the corresponding number.

Technical specifications

All models of Kupper brand boilers are equipped with a block of heating elements with a total power of 6 kW (only for OK 30 - 9 kW) and a TB-63 thermometer (installed on the side or front wall). Other characteristics:

- The efficiency of solid fuel boilers is 75–84%;

- heat exchanger jacket volume - 25–50 l;

- the permissible maximum liquid temperature at the boiler outlet is 95 °C.

Converting Kupper series boilers to a different type of fuel does not require complex welding and leads to improved performance. The manufacturer offers specially designed gas-burners AGG-13K and AGG-26K, the thermal power of which is 13 kW and 26 kW, respectively, or pellet - APG-25. Customer reviews and technical characteristics of Kupper pellet heating boilers indicate their high efficiency and safety. For example, efficiency increases to 95%; The burner has photocells, which, when the flame is extinguished, start the automatic ignition process.

Tips for choosing

First, the type of fuel and boiler power are determined. To accurately calculate the last parameter, you will need the help of a specialist. If this is not possible, the area of the heated room is divided by 10 and a reserve of boiler power is added - another 25%.

Cooper cost

The heating equipment of the Teplodar company has an ideal price-quality ratio. Experts note that prices for pellet boilers lower than corresponding models from other manufacturers. For example:

| Model | Heated area (up to), m2 | Dimensions, mm | Weight, kg | Price, rubles |

| basic version | ||||

| OVK 10 | 100 | 750x430x505 | 84 | 18500-22430 |

| OK 15 | 150 | 754x415x556 | 98 | 21000-22820 |

| OVK 18 | 180 | 740x485x650 | 120 | 22800-27560 |

| OK 20 | 200 | 740x485x660 | 115 | 23900-25940 |

| OK 30 | 300 | 995x485x645 | 145 | 30500-33310 |

| pellet | ||||

| OVK 10 | 100 | 750x430x675 | 132 | 84838-90440 |

| OK 15 | 150 | 745x415x726 | 146 | 90 830-91900 |

| OVK 18 | 180 | 740x485x830 | 168 | 81850-95570 |

| OK 20 | 200 | 740x485x830 | 163 | 93950-94900 |

| OK 30 | 300 | 995x485x815 | 193 | 101320-102900 |