To maintain normal humidity and temperature in the house, ensure constant air exchange in residential and non-residential premises, it is necessary to properly and efficiently equip the ventilation system. Despite the huge number of new systems for arranging ventilation shafts, solid brick remains the most popular building material for these purposes.

In case of shortage solid brick it can be replaced with facing hollow bricks, but subject to careful filling of all existing voids with mortar. When constructing air ducts, it is not recommended to use sand-lime brick, which does not tolerate temperature changes well, as a result of which it crumbles and collapses.

- ability to withstand high temperatures;

- ease of operation;

- durability.

Brick ventilation ducts are air ducts in which the air moves due to pressure differences ( natural ventilation) or using a fan (mechanical ventilation). In the first case, the installation of a deflector will increase the efficiency of the ventilation system.

Features of brick ventilation ducts

Brick ventilation systems must be equipped in accordance with the design scheme and compliance with all norms and regulations, including fire safety. It is prohibited to place ventilation ducts close to fireplaces and stoves.

Brickwork ventilation shafts are usually located with inside load-bearing walls. Separators in the masonry of channels should be 1/2 the length of the brick. done using a single-row or multi-row dressing system. All channels must be well connected to each other. In this case, the internal surfaces of the shafts should not have any protrusions. In addition, in the junction of ventilation ducts with floor slabs, the ends of the slabs should not protrude into inner part mines

Features of masonry

The mortar used for laying brick air ducts is the same as for laying walls. However, you should pay attention to the quality of the sand and the strength of the cement. Poor-quality mortar components can lead to a decrease in the strength of the masonry and rapid clogging of the shaft.

Brick ventilation ducts can be vertical or inclined (with an outlet level of up to 1 m). The most common is the masonry of a vertical square course with a side of 2 bricks. Before proceeding directly to the laying of the air duct, it is necessary to perform preliminary markings using a template. To ensure the correct shape of the ventilation ducts, after laying the first three rows, buoys are installed plumb. The bricks are laid using end-to-end technique, which prevents accidental ingress of combustion products into adjacent channels or into the room.

- The laying of ventilation ducts should be made of solid brick. It is important to remember the dressing rules.

- The standard dimensions of ventilation ducts in brickwork are 14x14 centimeters, chimneys are slightly larger - 27x14 centimeters. The wall thickness is at least half a brick.

- If the ventanal is located in external wall it must be insulated to ensure good traction.

- For laying channels, you can use the usual one. It is recommended to pre-moisten the brick with water to improve its adhesion.

- It is recommended to make the ventilation ducts as smooth as possible, that is, without roughness, protrusions or depressions, since all this interferes with normal air circulation.

- If there is a special hood, forced ventilation is strictly prohibited.

- Kitchens, bathrooms, toilets and storage rooms must be equipped with an exhaust vent and a ventilation duct.

- It is necessary to organize an air flow into the room, otherwise the ventilation will not work.

- In a room where there is a working fireplace, a separate ventilation duct should be installed so that the smoke that periodically enters the room during combustion goes outside.

- The maximum deflection angle of the vertical channel is 30 degrees, otherwise the ventilation of the room will be disrupted and additional ventilation devices will have to be installed.

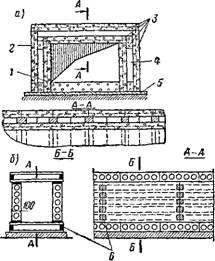

The outlet of the ventilation ducts of the 2nd floor of the house is shown in section 3-3.

The exit of ventilation ducts in the attic of a house is shown in section 4-4.

The exit of the ventilation ducts above the roof of the house is shown in section 5-5.

To mark the location of channels apply inventory template, which can be made from boards thick 25 mm, length 2500 mm and width 140 mm.

On the board make cuts for smoke and ventilation ducts. The template is laid on the masonry so that it the end was adjacent to the internal plane of the transverse wall, And by cutouts outline with chalk channel cross sections.

For the right direction channels in the masonry and ensuring their shape apply so-called buoys- wooden or metal templates, made in the form of boxes with cross-sectional shape of the channels.

The buoy template for laying ventilation ducts is shown in the diagram below.

Using buoys also helps protect channels from clogging during masonry. When the wall is ready to be laid buoys gradually move up:

- in the warm time - through every 6-8 rows masonry;

- in the cold- every 3-4 rows.

After finishing the masonry channels are checked, passing through them a ball with a diameter 100 mm tied on a cord.

Laying channels lead using the “end-to-end” method with cutting the solution.

To make channels, use ordinary bricks with appropriate ligation of channel masonry with wall masonry.

The channels are usually made vertical. In exceptional cases allow bends to a distance no more than 1 m And at an angle at least 60° to the horizon.

Channel cross section in all areas (vertical and branch) should be the same.

Laying inclined sections perform made of hewn bricks. When laying channels they use whole brick. Masonry seams carefully fill with solution.

Internal surfaces of channels as it progresses the masonry is rubbed down, the mortar flows are ground.

Laying channels perform on the same solutions, as masonry of internal walls Houses.

In residential, public and communal buildings, exhaust ventilation vertical ducts can be installed in the internal

brick walls ah, from special ventilation blocks, in the voids of internal walls from large blocks, in the form of attached ducts near internal walls and partitions, in the form of asbestos-cement ducts located in the voids of brick walls.

It is not recommended to place ventilation ducts in the thickness of the walls of rooms with high air humidity; It is not permitted to place ventilation exhaust ducts in external walls to avoid condensation of water vapor.

The minimum cross-section of ventilation ducts installed in internal brick walls (Fig. X.19) should be half a brick per half brick (140X140 mm). The thickness of the walls of the channels and the thickness of the walls between channels of the same name are taken to be no less than the size of half a brick, and the thickness of the walls between channels of the same name - 4 - no less than the size of a brick (250 mm). Channel cross-section dimensions

In brick walls should be taken as multiples of the size of half a brick (140 mm). Channels in internal brick walls are allowed to be installed at a distance of at least 380 mm from doorways and wall joints. The internal surfaces of the channel walls are made smooth with grouting of the joints.

In the absence of brick main internal walls, attached ventilation ducts are made from blocks or slabs (slag gypsum and slag concrete, concrete, gypsum fiber, slag concrete hollow, clay foam and foam silicate), from asbestos-cement pipes, sheet steel, plastic. The minimum cross-section of channels is 100X150 mm. Attached ventilation ducts in rooms with normal heat and humidity conditions are made of slag gypsum and gypsum fiber boards 35 mm thick, and in wet rooms - from slag concrete or concrete slabs 40 mm thick or from thin sheet steel painted with oil paint.

Attachment channels are located at internal walls or partitions, and, if necessary, at external walls. In the latter case, an air gap of at least 50 mm thick or insulation is installed between the wall and the channel.

IN modern construction For ventilation purposes, special ventilation vents are used. concrete blocks with inclined channels (Fig. X.20) and ventilation wall panels(Fig. X.21) with vertical channels installed as partitions.

Horizontal ventilation ducts connecting ventilated rooms with vertical exhaust ducts are installed suspended or suspended (in corridors) (Fig. X.22). Sometimes voids in concrete flooring are used as channels.

When laying exhaust ventilation ducts in attics or in unheated rooms to remove air from residential premises and classrooms, they are made of double slag-gypsum boards, each 40 mm thick, with an air gap between them 40 mm thick (Fig. X.23, a), and for removal air from kitchen premises, sanitary facilities and house laundries - made of slag concrete slabs. Ventilation ducts in the attic can also be made from various slag-gypsum or slag-concrete slabs with a thickness of 100 mm (Fig. X.23,b). For the installation of exhaust ducts laid in attics for ventilation systems of rooms with high humidity Roofing or sheet steel can be used, which is carefully painted. In this case, steel air ducts must be thermally insulated.

In industrial buildings, round and round steel air ducts are used in ventilation systems. rectangular section. Preference should be given to air ducts round section. The use of rectangular air ducts must be justified by the requirements for creating a specific interior in a workshop or room or other conditions.

To move air with temperatures up to 70° C and normal humidity, you can use air ducts made of sheet or roofing steel. When transporting air from high humidity, and also when laying ventilation ducts outdoors, air ducts made of roofing or sheet steel coated with protective waterproof varnishes and paints, as well as polymeric materials or galvanized steel are used. To move air containing chemically active gases and vapors of acids or alkalis, air ducts made of acid-resistant steel, sheet steel with protective coatings, vinyl, vinyl plastic, ceramics and acid-resistant concrete are used. In some cases, it is possible to use aluminum ducts. To move air with a temperature above 100 ° C, which does not contain chemically active gases, air ducts made of sheet steel with a thickness of more than 1 mm are used. In pneumatic transport systems it is recommended

Rice. X.23. Installation of ventilation ducts in the attic

A-from slabs 40 mm thick; b - the same, 100 mm; 1 - plaster shingles; 2 - steel reinforcement, 3 - slag-gypsum slabs; 4- air gap; 5 - wooden flooring; 6~ Place of thorough sealing with plaster to a depth of 25 mm

It is recommended to use air ducts made of sheet steel with a thickness of at least 1 mm.

As already mentioned, for most air ducts in industrial ventilation systems a round cross-section is adopted, since it is characterized by less resistance to air movement, less metal consumption and more simple installation compared to a rectangular section. The advantage of rectangular air ducts is their ease of placement indoors.

To facilitate the mechanized preparation of air ducts and fittings of round and rectangular cross-section, normals have been created for them.

For air ducts and fittings with a circular cross-section, the following diameters are established: 100, 110, 125, 160, 200, 250, 280, 315, 400, 500, 630, 710, 800, 900, 1000, 1120, 1250, 1400, 1600 mm.

For aspiration (dust removal) systems, in addition to those listed, air ducts with a diameter of 140, 180, 225, 355, 560 mm are made.

For rectangular air ducts made of steel sheet with a thickness of 0.7 mm, the following side dimensions are established: 160X160, 160X200, 200X200, 250X200, 250X250, 400X200, 400X250, 400X400 and 500X250 mm, and sheet 1 mm thick - from 500X400 to 2000X1600 mm (thirteen sizes).

Round air ducts are fastened using clamps (Fig. X.24) and brackets (Fig. X.25)."

Exhaust shafts. In Fig. X.26, and shows the exhaust shaft of ventilation systems for residential and public buildings with combined exhaust ducts, made of lightweight concrete. In Fig. X.26, b shows an exhaust shaft made of boards, upholstered on the inside with roofing steel on felt soaked in clay solution, and plastered on the outside.

|

|

Exhaust shafts for mechanical ventilation in industrial buildings are made of sheet steel and are not insulated, since air passes through them large number air that does not have time to cool to the dew point temperature, i.e. there is no fear of condensation of water vapor. This danger may arise when the fan is stopped.

A - diameter up to 315 mm; b - diameter 400-1600 mm

|

|

|

"i 111-a i (i / i ___ i |

||

|

І pі m і" ii ptg |

||

Figure X 26. Exhaust shafts

1 - deflector; 2 - bolts for fastening the deflector, embedded in the walls of the shaft; 3 - throttle valves; 4 - hatch for repair of throttle valve

Fig X27. Flare release

1 - diclon-washer; 2 - flexible insert; 3 - throttle valve; 4 - discharge shaft with flare emission, 5 - centrifugal fan; 6 - vibration-isolating base

Torah, and therefore for such systems it is necessary to organize drainage of condensate formed during this period. Exhaust shafts are equipped with umbrellas and deflectors. Currently, flare emissions are used to remove contaminated air by installing nozzles on exhaust shafts (Fig. X.27).

Fire safety requirements. When installed, various rooms and floors are connected to each other by channels and air ducts, which can serve as a source fire danger. In this regard, the material of channels and air ducts and their laying must meet the requirements of SNiP, which determine the provision of explosion and fire safety.

Recently, ventilation outlets have been constructed from metal. However, the classic brick version still exists, at least for decorative purposes.

As a material for laying out ventilation shafts, would be better suited red solid brick. It is also possible to use hollow facing stone. But in this case, the cavity is filled with clay or mortar when laying each row. It is unacceptable to build ventilation shafts from sand-lime brick because it does not tolerate high temperatures well.

Performance technique

There are no special requirements for this job. The preparation of masonry mortar is carried out using the same technology as for the construction of walls: 1 part of cement is mixed with 3 parts of sand, water is added according to consistency. Everything is thoroughly mixed until homogeneous mass. The sand just needs to be carefully sifted, because foreign elements and inclusions of fine gravel make the mixture weak, it will collapse, crumble and, accordingly, accumulate in the ventilation shaft.

It is recommended to monitor the moisture content of the sand, and use M-500 grade cement for the mixture. The solution prepared using it is more plastic and better suited for such work. You can check if it is ready by tilting the container at an angle of 40 degrees. If the solution does not spill out, but remains in it as a thick mass, then it has excellent plasticity and is ready for use.

It is recommended to monitor the moisture content of the sand, and use M-500 grade cement for the mixture. The solution prepared using it is more plastic and better suited for such work. You can check if it is ready by tilting the container at an angle of 40 degrees. If the solution does not spill out, but remains in it as a thick mass, then it has excellent plasticity and is ready for use.

Design features

The design of ventilation ducts may vary. The most common and simplest option is the one with vertical masonry of a square exit. First, markings are made. There is a special tool for this. After this, bricks are laid in 2-3 rows, and “buoys” are mounted along the established plumb line - bricks that perform protective function channel and serving as additional markings. They are laid out across the shaft with the end part.

How structural part, they also provide strength, but pose minor problems during chimney cleaning activities. Wall masonry ventilation duct, performed in two bricks, using a multi-row dressing system. Connection point with load-bearing wall or a partition is reliably sealed by grouting the joints. This is necessary so that during operation, combustion products do not enter the living space.

Negatives

A structural disadvantage of brick ventilation shafts is considered to be small side effects. In addition to their direct purpose, they  They let the heat out. To reduce these indicators and not resort to additional insulation of brick walls, it is necessary to provide a bend inside the shaft to retain the escaping air. The brick is laid out with a ladder, the protruding niches are sealed with mortar, and in the lifting areas the stone is placed on the edge and then pressed against the next masonry row.

They let the heat out. To reduce these indicators and not resort to additional insulation of brick walls, it is necessary to provide a bend inside the shaft to retain the escaping air. The brick is laid out with a ladder, the protruding niches are sealed with mortar, and in the lifting areas the stone is placed on the edge and then pressed against the next masonry row.

At the point where the ventilation duct exits to the roof, you need to provide an air gap of 13-15 cm. Connections of the chimney with roofing material There should not be, according to fire safety standards. The defect is covered with a special galvanized apron.

The operation of the ventilation duct is negatively affected by overcooling of the exhaust gases. Inside the passage, due to temperature changes, condensation begins to form and it all settles on the brickwork, which, being oversaturated with moisture, becomes the result of weakening internal draft. In order not to violate safety regulations, which will subsequently lead to disastrous results, the distance from the inner wall of stone to the outside of the metal air duct should be 1.5-2 bricks.

Often, for decorative purposes, brick air ducts are laid out not in the classical way (vertically), but at a slight slope, with a drainage level of up to 1.5 meters. This requires a different material. Hewn brick - its structure does not create resistance to the movement of internal gases.

Ventilation ducts are now very often made of metal, but the classic version, which is brick ventilation ducts, is still popular in the construction of houses. They are located in interior walls buildings. The cross-section of the channels of such an air duct is 1X1/2 or 1/2X1/2 brick.

There is no way to build a brick house without ventilation ducts.

The best option for constructing brick ventilation ducts is to use solid brick, but if it is absent or in short supply, you can also use hollow facing brick, the cavities of which are filled with mortar or ordinary clay. It should be remembered that this is unacceptable, since it does not tolerate temperature changes very well and begins to crumble.

Preparation of mortar, materials, masonry technique

Laying brick ventilation ducts involves using the same mortar as for laying internal walls.

Laying chimneys and ventilation ducts: a) in walls 1.5 bricks thick; b) in walls 2 bricks thick.

To prepare it, add 3 parts sand to 1 part cement. Sand must be used clean, since foreign impurities weaken the solution and, as a result, the entire ventilation duct. You should also remember about the moisture level of the sand. It is preferable to use grade M-500 cement, since it has excellent plastic properties and is ideal for this type of work. Having thoroughly mixed the resulting dry mixture in a specially designated container, pour water into it, while constantly stirring the solution until the required consistency is obtained. This is checked as follows: the container is tilted at an angle of 40 degrees, and if the solution does not spill out, then it is ready for use. If the volumes of the prepared solution are quite large, then it is more reasonable to use a concrete mixer with an electric drive to mix it.

The design features of brick ventilation ducts can vary greatly depending on their purpose. The most common and classic option is to lay a vertical square course with a side of 2 bricks. The first stage is preliminary marking, which is carried out using a template. After this, several (usually 2-3) rows are laid and buoys are installed plumb - bricks laid across the channel. They are necessary to ensure the correct shape of the ventilation ducts and protect them from contamination while brickwork. They give strength to the ventilation duct, but create quite big problems when cleaning the chimney. After 5-6 rows the buoys are rearranged. Ventilation ducts are laid using a multi-row or single-row suture ligation system.

It is necessary to use the technique of laying bricks end to end. This will prevent the penetration of combustion products into living spaces or adjacent ventilation ducts during operation of the duct.

Negatives

The disadvantage of such a chimney is that it releases not only smoke, but also heat into the street. To avoid this, it is necessary to make a bend in the channel, which will help retain some of the heat inside it. To do this, the bricks are laid in a ladder, the niches are filled with mortar and they are laid on this hill, and then they are pressed on top with a new row of bricks.

At the point where the chimney exits through the roof, an air gap of at least 13 cm wide must be left. The chimney is connected to the roof of the house using special galvanized steel aprons. Overcooling of the flue gases inside the ventilation duct can lead to the following: condensation forms inside the duct, the brickwork becomes oversaturated with moisture and the draft inside the air duct weakens. To avoid this, the distance from the outer surface of the walls to the inner surface of the chimney should be 1.5 bricks at an outside air temperature of 20 ° C and above, 2 bricks from -20 to -30 ° C and 2.5 bricks at a temperature below - 30 °C.

Often in multi-storey buildings They lay out not classic vertical, but inclined ventilation shafts with an exhaust level of up to 1 m. Such masonry is made with hewn bricks to ensure the least resistance to the movement of exhaust gases. After the masonry is completed, to accurately determine the location of the blockage in the ventilation duct, an iron ball on a rope is lowered into it, and the location of the blockage is determined by the presence of resistance.