Approved by an expert

One of the most common devices that can provide uninterrupted hot water at home is a gas water heater. It perfectly copes with heating of any volume of water in the shortest possible time. At the same time, modern modifications allow you to clearly set the required temperature and automatically turn on and off in accordance with the operating mode of the draw-off point.

Instantaneous gas-fired water heaters are quite economical and safe to operate. The only inconvenience is the need to organize a high-quality removal of combustion products. Once and for all, this problem can be solved only with the help of a competent installation of an exhaust pipe for a gas column. When choosing the parameters and configuration of the flue system, follow the manufacturer's instructions and current regulations.

According to the table of definitions NPB 252-98, the exhaust pipe for the gas column is the connecting pipe for the flue pipe of the apparatus and the smoke channel. Accordingly, it transports the products of gas combustion and must meet the requirements for chimneys. Failure to comply with them is fraught with gas contamination of the room and carbon monoxide poisoning.

All requirements for chimneys are set out in the following regulatory documents:

- NPB 252–98;

- Rules for the production of pipe and furnace work VDPO;

- SP 42-101-2003, Appendix D

- SP 60.13330.2012, which is an updated version of SNiP 41-01-2003 (replacing SNiP 2.04.05–91).

The main provisions that directly relate to smoke removal from domestic gas water heaters are as follows:

- The cross-sectional area of the exhaust pipe is taken not less than the cross-section of the outlet pipe of the unit;

- It is necessary to ensure the complete tightness of the chimney, its resistance to corrosion and high temperatures up to 200 ° C;

- The laying of connecting pipes through living rooms is prohibited;

- The vertical section of the exhaust pipe at the outlet of the column must be at least 500 mm high, in some cases it can be reduced to 250 mm;

- Connecting pipes should be up to 3 m long in new buildings and up to 6 m in existing ones;

- It is allowed to use no more than 3 turns with a bending radius not less than the diameter;

- The exhaust pipe is installed at a distance of at least 5 cm from the ceiling or wall of non-combustible materials, but if they are combustible or slow-burning, then at least 25 cm. The distance can be reduced to 10 cm by taking protective measures in accordance with SP 42-101-2003;

- If the connecting pipe for the geyser passes through an unheated room, then thermal insulation must be used;

- The chimney must be laid with a slope of 0.01 or more towards the appliance.

Important! Removal of combustion products is possible only through smoke ducts or specially installed chimneys; the use of ventilation ducts is strictly prohibited.

Smoke channels are arranged in walls made of non-combustible materials and insulated, if necessary, to prevent condensation. If there are no suitable walls or no channels are provided in the building in use for the removal of combustion products, then a chimney of a wall-mounted or root type is installed.

Each fuel-burning device must have a separate smoke channel or pipe. In some cases, it is allowed to remove exhaust gases from the column and the boiler into one chimney with an increase in the cross section of the pipe. In this case, the introduction of combustion products into the channel should be carried out at different levels at a distance of at least 0.75 m or at the same level using a cut with a height of 0.75 m and a thickness of 0.12 m.

The chimney must be strictly vertical and have a removable socket at the base or a pocket 250 mm deep with a door for cleaning soot. If it is necessary to bypass existing obstacles, a deviation of up to 30 ° from the vertical is allowed, while the cross-sectional area is preserved, and the offset should not exceed 1 m.

On a note: the round or rectangular hole under the flue inlet is intended for soot cleaning and must always be accessible for maintenance. When doing general cleaning in the kitchen, do not forget to open the door and clean out the soot, leaves and other debris.

The height of the chimney is a key factor in creating good draft. It is she who is decisive in the issue of high-quality removal of combustion products. The height of the chimney must be determined in accordance with the scheme given in SP 42-101-2003 (Appendix D).

If there are taller buildings or trees in the vicinity, the height of the wind support area must be additionally checked and, if necessary, the height of the chimney must be increased. In any case, the elevation above the adjacent part of the roof must be at least 50 cm, and with a combined (flat) roof - at least 200 cm.

After the installation is completed, the tightness of the flue pipe and the presence of draft must be checked. In order to avoid the risk of draft disappearance as a result of freezing of the head or its overlapping with foreign objects, it is forbidden to use nozzles on chimneys in the form of umbrellas, deflectors, etc.

On a note: in rooms with hermetically sealed windows, the geyser may periodically turn off due to insufficient air flow. Automation stops the operation of the water heater to prevent back draft, which may occur due to rarefaction of the air in the room. To fix the problem, it is enough to keep the kitchen window in micro-ventilation mode while the column is running.

Selection of pipeline material

When going to buy an exhaust pipe, you need to carefully study the installation conditions, know the model of the geyser, the diameter of the smoke exhaust pipe and the required lengths of the pipeline sections. It is advisable to stock up on the layout of the water heater indicating all the distances, this will help you better navigate when choosing the necessary elements and, if necessary, get expert advice.

According to SP 60.13330.2012, connecting and chimney pipes must be made of non-combustible materials with an equivalent inner surface roughness of not more than 1.0 mm. In addition, they must be tight with tightness class B and prevent air leaks at the joints and at the junction with the smoke channel. The use of materials such as ceramics and stainless steel is recommended.

SP 42-101-2003 allows the use of roofing or galvanized steel with a thickness of 1 mm or more, flexible metal corrugated pipes and unified elements supplied with the unit.

It is very important that the material of the chimney is resistant to corrosion, as condensate can quickly destroy it. The smoother the inner surface, the less soot will collect on it. The roughness of the outer surface is not standardized, but from the point of view of ease of cleaning, a smoother material for the connecting pipe will be more practical.

However, corrugated pipes are quite popular for connecting a geyser to a smoke channel. They are easy to work with and very comfortable in tight spaces. Their use allows you to successfully avoid obstacles and carry out concealed installation, hiding equipment in cabinets and closing the pipeline with removable panels.

The main disadvantage of corrugated pipes is the possibility of burnout under the influence of high temperatures. Therefore, for fire safety purposes, it is recommended to use stainless steel corrugation, and not cheaper aluminum.

Galvanized steel with a thickness of 1 mm is a perfectly acceptable material, but there is an opinion that galvanizing can release harmful substances when heated strongly. Accordingly, its use is undesirable for models with high flue gas temperatures.

The ideal material in terms of durability, aesthetics and compliance with all requirements is stainless steel. It is not threatened by corrosion, burnout, dust accumulation, or accidental damage. Quite naturally, it turns out to be the most expensive.

Mounting order

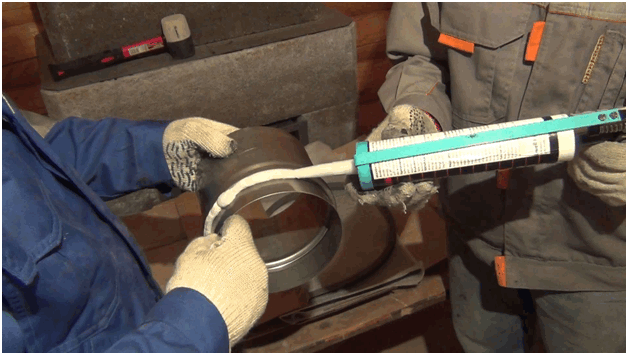

Installation of an exhaust pipe for a geyser from any material begins with taking measurements and preparing all the necessary elements. In the case of corrugation, the procedure for carrying out the work is very simple. It is enough to take the pipeline of the required length, put it on the flue pipe of the water heater and clamp it with a clamp. The free end is inserted into the decorative ring and fixed in the opening of the smoke channel. The main thing here is to match the diameter of the corrugated pipe with the size of the outlet of the column.

For all other materials, it is necessary to prepare the required number of straight and rotary elements that will be inserted into each other, forming the desired chimney configuration according to the design principle. Rotation angles are standard or custom-made for specific dimensions.

When assembling, ensure the maximum tightness of the connections. The entry of one element into another must be at least half the diameter. For better sealing, a heat-resistant sealant is used. The joints are fastened with clamps and are located outside the ceilings in free access.

When fixing the exhaust pipe for the gas column, it is necessary to exclude the possibility of deflection, as well as contact with electrical wiring, gas pipes and other communications. To pass through the floors and roofs, it is necessary to use additional thermal insulation or a special unit - cutting.

Due to the limitation on the number of allowed turns, the number of possible chimney configurations is rather limited. In total, there are three main options, depending on the location of the exhaust opening. Two more can be obtained by mirroring the previous ones.

All the requirements and recommendations set out above apply to devices with an open combustion chamber. The norms also allow the removal of combustion products through an external wall without a vertical smoke channel from gas water heaters with a closed combustion chamber and forced exhaust gases. In this case, installation is carried out according to the manufacturer's instructions in compliance with the standard distances and lengths of the coaxial chimney specified in SP 42-101-2003.

Conclusion

Thus, the installation of an exhaust pipe for a geyser has many important nuances. Given the great danger that can arise from non-compliance or partial violation of regulatory requirements, it is necessary to approach this issue with the utmost seriousness and, if possible, entrust the execution of all work to professionals.

High-quality installation of the connecting pipe is the key to the safe operation of the geyser. Strict observance of all the requirements of regulatory documents will ensure the stability of the device and allow the owners to use a convenient water heater without fear of carbon monoxide poisoning.